Another successful Open House For Multivac Canada

By Canadian Packaging staff

Automation Blue Danube Sausage House Limited Canadian Select Meats Inc. Finest Sausage & Meat Ltd. Handtmann Canada Ltd. Handtmann GMD 99-2 inline grinding system Handtmann VF 838S vacuum filler Intray.DK tray dispensing system Multivac Canada Inc. Multivac Canada Open House Multivac T 600 traysealer Ryding Regency Meat Packers Ltd. Schneider Electric Magelis HMIHeld at its Canadian headquarters in Brampton, Ont. Multivac Canada organized an Open House event for would-be customers to come in and learn first-hand all about the latest in packaging technologies.

As a leading global manufacturer of packaging machines, Multivac is not the type of company to sit on its laurels.

Multivac Canada Inc.’s Canadian headquarters, located in Brampton, Ont., has signage within its Training and Innovation Centre that proudly states “Fully automated. Totally integrated.”

Truth be told, after yet another successful, well-attended Open House event held on June 8, 2018, the signage should also include “Always engaged.”

Multivac Canada regional sales manager Sonia Tarantini (left) discusses some of the finer points of the capabilities of the Multivac L310 Labeller with a visitor to the packaging machinery manufacturer’s Open House.

Along with partner Handtmann Canada Ltd., Multivac operated a complete processing and packaging line within the Centre demonstrating to visitors and would-be customers, showing the smooth operating capabilities both companies provide.

The Training and Innovation Centre is not just a static showroom, rather it is a fully-operation site that not only allows its customers to test the capabilities of the machines before purchasing it, but also informs the customer of just what sort of machinery they might require to create the optimal production/packaging line for brand appearance, and cost efficiency.

Along with the visitors, both Multivac and Handtmann ensured they had plenty of experts available to not only discuss their needs, offer suggestions regarding machinery, but also explain in layman terms how the equipment not only works, but performs—along with live demonstrations of the machines in operation.

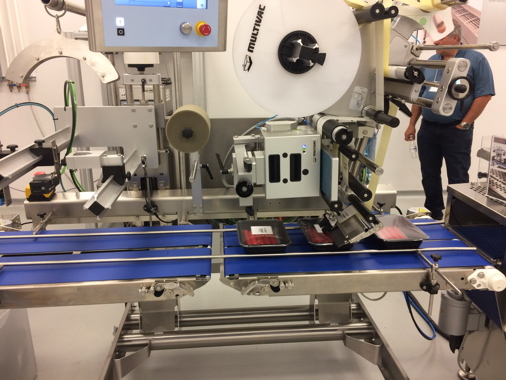

A reverse line view of (from left) the Multivac L310 Labeller; Multivac T 600 thermoformer traysealer, Handtmann GMD 99-2 inline grinding system and Handtmann VF 838S vacuum filling system at the Multivac Canada headquarters in Brampton, Ont.

A newly-installed fully-automated line at the Centre consisted of:

- A Handtmann VF 838S vacuum filler with an automatic lifter to move product up and in to the unit. Featuring a high filling pressure, the filler is ideal for the sausage industry—dry, fresh or even industrial meat production. At the Open House, modeling clay was used to simulate food products of various shapes and sizes.

Product passes through a Handtmann GMD 99-2 inline grinding system and onto a tray from an Intray.DK and on its way to a Multivac T 600 traysealer.

- From there, the product moves through a Handtmann GMD 99-2 inline grinding system providing high levels of hygiene, durability and production, using—depending on customer requirements—a wire cutter or a blade.

- Product then moves onto a tray dispensed via Intray.DK system featuring a Schneider Electric Magelis HMI (human-machine interface).

The Multivac T 600 traysealer—the smallest, fully-automatic traysealer that can be integrated within a packaging line.

- With the product in the tray, it is conveyed to a Multivac T 600 traysealer before being automatically labeled by the company’s L310 Labeller.

The Multivac L310 Labeller at work.

The T 600 from Multivac is the smallest, fully-automatic traysealer that can be integrated within a packaging line to pack food, medical and pharmaceutical products, industrial as well as consumer goods.

Replete with energy-efficient drive systems, ease-of-washdown, and fast die changes, the T 600 traysealer offers quick and efficient pack output with gentle tray handling. Along with MAP, and EMAP pack types, it can also create vacuum skin packs—all with the usual Multivac penchant for top-notch sealing capabilities.

A Handtmann engineer discusses the efficiency prowess of the Handtmann VF 838S vacuum filler with automatic lifter.

Nick Balega, president of the family-owned Blue Danube Sausage House Limited who create Hungarian and European deli meats, says the event was eye-opening. “We had a great time, and we had an opportunity to see a lot of wonderful equipment in action.” (You can read a 2013 article done by Canadian Packaging magazine on Blue Danube HERE.)

Another visitor to the Centre that day was even more effusive in his praise, Shannon Desborough, owner of Finest Sausage & Meat Ltd. of Kitchener, Ont., who says: “I’ve known them (Multivac) for years. It’s interesting to see real-time demonstrations of what the machines can do, to see the machines in action.

“We have so many products and ideas,” he continues, “but we walk in here, and see the Multivac machines in action, and it opens up my eyes to the possibilities of how we could do things in different ways.”

A Multivac engineer discusses with a crowd of visitors just what the Multivac T 600 thermoformer traysealer can do to pack product and extend its product shelf-life over other forms of packaging.

Other equipment showcased at the Open House event include:

- Multivac R105 thermoformer;

- Multivac R105 MultiFresh thermoformer with a Multivac MBS 220 converger;

- Handtmann VF 608B grinder working with a Verbufa VDM depositing system moving it into a Multivac R145 thermoformer unit;

- Inotech WT99-IT-STD sausage link cutter capable of taking a job that one person can do in a work shift and performing it in 12 minutes;

- Multivac P600 double chamber vacuum chamber, and a;

- Multivac Baseline P200 vacuum chamber system.

Canadian Select Meats Inc./Ryding Regency Meat Packers Ltd. are two meat processing companies operating in west Toronto. Representing both businesses, Anthony Petronaci came to see the equipment in action at the Multivac Canada Open House.

Petronaci says, “I don’t get much of an opportunity to visit the Multivac facility, but it is always good to see how things are operating before we make a decision on any capital investment.”

Advertisement