An impressive variety, also in terms of packaging

By Markus Vogelmann, Verkauf / Sales Account Manager at Gerhard Schubert GmbH

Automation Cans Case Packing Robotics Innopack TLM KHS Rotkäppchen-Mumm Sektkellereien SchubertSchubert’s Innopack TLM provides Rotkäppchen-Mumm Sektkellereien with over a dozen formats

Markus Vogelmann, Verkauf / Sales Account Manager at Gerhard Schubert GmbH

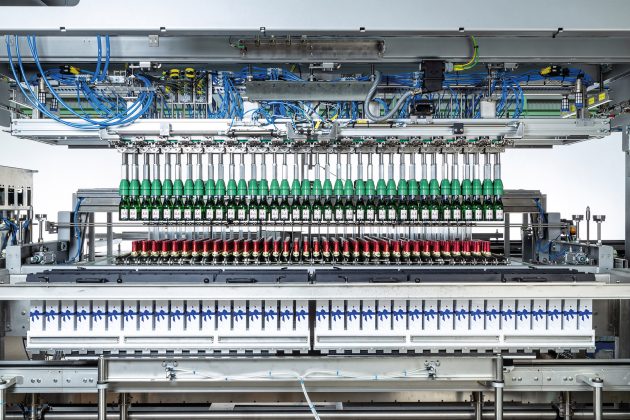

Rotkäppchen-Mumm Sektkellereien covers (almost) every wine drinker’s wish list with a wide, comprehensive range of products. A packaging machine offering flexibility, quick format changes and excellent performance is needed to ensure that both large and small bottles are packed in an appealing and versatile way. Ultimately, only the Innopack TLM from Schubert and KHS could take on the challenge. Currently, it is the only available packaging machine that can handle this wealth of variants economically and reliably.

Rotkäppchen-Mumm Sektkellereien, headquartered in Freyburg on the River Unstrut in eastern Germany, can look back on a company history of 180 years and has grown into a world-leading manufacturer of sparkling wine, wine and spirits. The company is the market leader within this sector in Germany. The MMchen, the Piccolos of the well-known and successful brand MM Extra, have been a household name for connoisseurs for decades. The assortment is now much more extensive and offers the right product for everyone: whether Rotkäppchen Flaschengärung Riesling, alcohol-free Mumm Rosé Dry or Jules Mumm.

The KHS packer places the bottles into the erected gift packs positioned on the waiting Transmodul.

Fast-moving trade, flexible machine

The packaging for this sparkling variety needs to be as multifaceted as the product itself for the trade and the end-consumer. The packaging variants range from batches to individual bottles in a gift pack, which are bundled in wrap-around cartons of 24 for ease of transport, to clusters of 4 bottles. The list already included nine formats when Schubert took in the order. Further formats were added during the commissioning of the machine. This is also due to the fact that market requirements are changing ever faster and the shelf space provided by retailers is not always increasing despite the growing variety of products. This is why for example, in the future, 12-pack cartons will have to be filled with two 6-packs instead of the previous three times four bottles. At the same time, Rotkäppchen-Mumm is continuously expanding its range, whether in terms of varities or bottle volumes. With this in mind, the Innopack TLM will be able to pack 0,75 l wine bottles, for example, quickly and safely in wrap-around cartons holding six bottles.

Two in one: filling and packaging beverages

Because of these complex requirements, Rotkäppchen-Mumm opted for an Innopack TLM: a combination of a KHS packer and a TLM system from Schubert. This block solution from the two leading system manufacturers implements all desired formats in a single machine and with up to 600 products per minute. It is designed in such a way that only a few format changes are necessary and tools can be changed quickly. The Innopack TLM will also effortlessly create additional packaging variants which can be implemented in the future. “It was extremely important for us to know that our new packaging machine would enable us to meet all the requirements of the retail trade for many years to come,” says Joachim Engler, Technical Manager at Rotkäppchen-Mumm, underlining the decision in favour of the Schubert and KHS solution.

F2 robots take the filled and sealed gift packages from the Transmodul and place them in the sales cartons.

A smooth collaboration

The Innopack TLM developed for Rotkäppchen-Mumm consists of a total of 13 sub-machines with a total length of 33 metres. They successfully master the enormous complexity of the required packaging tasks and are operated according to format and required capacity. In the case of gift packaging for the MMchen, for example, up to ten sub-machines can be used. In the first two sub-machines, F3 robots take up to 550 blanks per minute from the magazine, depending on the desired output. F2 robots pick up the individual packs lying in a row, straighten them up during transfer and place them on a Transmodul for further processing. On the way to the next sub-machine, the tabs are glued. There, F2 robots seal the underside of the gift packs, stand them up and place them in rows of two on another Transmodul line. The KHS packer feeds the small bottles and carefully places them into the open top gift packs. In the next two sub-machines, four F2 robots then also seal the top of the packaging and place it on one of two further Transmodul sections for pre-grouping.

Ready for delivery to customers: The sales cartons containing the gift packaging are sealed by F2 robots.

Securely packed and sealed

Shortly before the end of the packaging process, the sales cartons come into play: similarly to the gift packages, they are unstacked, erected and placed on their own Transmodul line. In the second to last sub-machine, two F2 robots lift and transfer the prepared MMchen into the outer cartons – in four groups of six products. The Schubert machine fills up to 23 sales cartons per minute, with three Transmodul lines working in parallel. To ensure that Rotkäppchen-Mumm can finally transport everything safely to the customers, the tabs of the large outer cartons are also glued and closed on the upper side.

The Innopack TLM of Rotkäppchen-Mumm currently already packs nine formats, and many more options are planned.

Transmodul as a connecting element

The Transmodul is what enables the Schubert and KHS components to work so well together. These Schubert transport robots can move around the whole line without restrictions thanks to an inductive energy supply, and radio transmission of data and signals. In the Rotkäppchen-Mumm machine, up to six Transmodul lines are in operation. The control of the entire system is implemented with only two operator terminals and a uniform software. This guarantees easy handling of the Innopack TLM.

The range of Fruchtsecco fruity sparkling wines currently comprises six alcoholic and two non-alcoholic varieties, including the fruity-tart pomegranate flavour.

A worthwhile investment: more formats, twice the speed

Thanks to the Innopack TLM from KHS and Schubert, the company benefits from a variety of formats that no other manufacturer could have implemented in a single machine. Last but not least, it is important to note that this new system works twice as fast as the previous machine of the sparkling wine, wine and spirits manufacturer.

Advertisement