See video – x-ray product “reclaim” service saves food companies thousands of dollars in potential lost product

Canadian Packaging

“Don’t send product to landfills that can be saved by an x-ray detection reclaim service!”

In this video, Plan Automation outlines a unique service food companies are now using to run x-ray inspections of product lots suspected of having metal or foreign object contaminants.

“Last year, over 200 customers diverted more than 5 million pounds of food from landfills with a value of over $10 million, “explains Plan Automation’s Scott Holmes.

Take a quick tour of the new 15,000 square foot facility in Bolton, ON as it receives steady shipments of goods for product inspection and reclaim services.

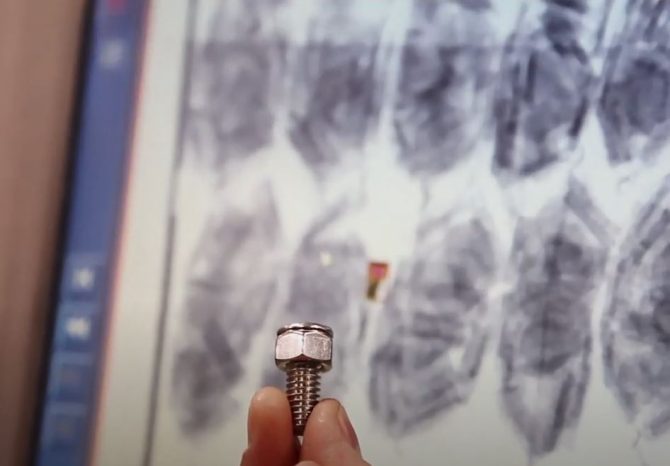

Company principal Mat Bedard shows us two types of product reclaim detection services. First, full shipper cases with multiple packages of baked goods move through a large aperture x-ray machine in search of a metal bolt hidden in one of the shipper cases. Watch as Mat “finds the needle in the haystack” which allows the customer to isolate the one offending shipper case …saving over $500,000 as the other shipper cases were rescued and reclaimed for distribution.

In a second case, Mat demonstrates how one cookie maker who suspected fine metal shavings in some product was able through a package by package X-Ray analysis find the 6 contaminants that were as small as 0.3 mm. The rest of the production run was saved.

Don’t needlessly send food and other products to the landfill when you have this eco-friendly and money-saving service available.

Watch the video to see how you can save thousands the next time you suspect product contamination.

Advertisement