Evolution of the bottle

By Carol Zweep

Design & Innovation General Bottling Bottles Carol Zweep NSF InternationalNSF International manager of packaging, food and label compliance Carol Zweep looks at the evolution of the bottle, and where it is likely to go next.

Packaging in bottles is not a recent invention. Early examples of the bottle appeared in ancient civilizations of China, Greece and Rome and were made from clay and glass. The bottle is a rigid container that has a neck that is narrower than the body with a mouth that is sealed to hold liquids for consumption such as water, milk, soft drinks, beer, wine and cooking oil.

Historical Perspective

A turning point in the increased use and function of packaging was the Industrial Revolution. Use of machines led to mass produced goods. Agricultural workers migrated to the cities to work. Food that was previously grown and consumed locally had to be packaged, preserved and transported to feed the new working class. Glass became a popular material for bottles and found various applications for beverages. The invention of carbonated sodas led to use of glass bottles that were first sealed with a rubber washer and gasket system. Later, metal crown caps were used. Bottle resealability became a popular feature with the development of screw top caps.

Plastic Bottles

Following the invention of plastic, it was discovered that this material could easily be melted and molded into various shapes including plastic bottles. Plastic has the advantage of being more light weight and shatter resistant than glass. Various plastics have different physical and barrier properties that enable manufacturers to select the appropriate material and design to meet processing and shelf-life requirements of the food. For example, polypropylene is a material that can withstand high temperature retort processing. Beverages that are sensitive to oxidation (such as wine and beer) need bottles with an excellent oxygen barrier. This can be achieved by using multilayer materials, oxygen scavengers and coatings. Convenience and portability promoted the proliferation of single-serve bottles. Product differentiation is achieved by custom designing bottle shapes for aesthetics, functionality and strength.

Sustainability

With the increase in consumable goods came the concern about packaging waste. Light weighting bottles was one initiative to reduce the amount of packaging waste as well as cost. For example, from 2000 to 2014, the average weight of a 500 mL PET water bottle has declined 48 per cent to 9.89 g according to the International Bottled Water Association. Development of the recycling infrastructure and end use markets enabled successful recycling of plastics. Ice River Springs is the first bottled water company in North America to self-manufacture its own resin and produce plastic water bottles made of 100 per cent recycled plastic. Companies such as Coca Cola are making bottles using conventional plastics that are made from renewable plant material (sugar cane) instead of petroleum-based materials.

Novel Bottles

Another trend in the bottle industry is the use of aluminum to provide a novel and premium feel to bottles. Specialty or promotional beers in aluminum bottles have become popular.

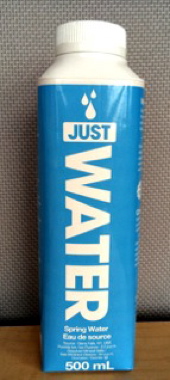

A novel twist to the bottle is Tetra Pak’s carton bottle (Tetra Top) with a screw-off cap. Tetra Pak claims that cartons are more sustainable than plastic bottles. The separable top allows for recycling of the plastic top and carton sleeve. The majority of the package is made from renewable resources; the cap and top are made from high-density polyethylene derived from sugar cane and the carton portion is mainly paper made from trees. Less energy is used in manufacturing the carton bottle compared to standard PET bottles and the carton material can be stored and transported flat.

What is the bottle of the future? Imagine an edible container of water made from seaweed that produces zero waste. Ooho! is a new kind of package created by Skipping Rocks Lab. It is made by treating spheres of ice with a liquid form of seaweed-derived membrane. The membrane solidifies and the water melts to create the edible water container.

The packaging industry has responded to the changing demand over the years. Innovation has proven to be the key to the evolution of the bottle. No doubt that packaging challenges will become even more complicated in the future.

Carol Zweep is the manager of packaging, food and label compliance for NSF International. Contact her via e-mail at czweep@nsf.org.

Advertisement