Tales from the bar side – September 2015, Canadian Packaging

By Andrew Joseph, Features Editor; Photos by Cole Garside

Automation Bottling Controls/Drives Arol S.p.a. Flying Monkeys Craft Brewery IDD Process & Packaging Krones Machinery Company Ltd. MicroStar Logistics Moore Packaging Corporation Omron Automation & Safety slideshow ULine Videojet Technologies Inc.Feisty Ontario craft brewer jumps through all the right hoops in relentless pursuit of hop perfection.

(From left): Flying Monkeys Craft Brewery president Peter Chiodo, Omron Automation & Safety account manager Ralph Nymann, Flying Monkeys automation specialist Chris Mavreas, and Omron industry marketing manager for food and beverage/packaging Laura Studwell with six examples of quality beer produced at the Barrie, Ont. craft brewery.

When most people think of flying monkeys, they probably recall the horrible little winged creatures that attacked Dorothy, Toto et al in The Wizard of Oz book and movie—or maybe they’ve had a beer or three.

Situated in the tres cool downtown section of Barrie, Ont., Flying Monkeys Craft Brewery has taken the art of beer to new heights with a wonderfully eclectic variety of tasty craft beers wrapped with witty monikers and brilliant psychedelic packaging.

The brewery first opened its doors in 2005 as the Robert Simpson Brewery named in honor of the long-passed first mayor of Barrie and himself a founder of a local brewery in the 19th century. For various reason, the company then changed the name to Flying Monkeys in 2009, a progressive step that actually brought the brewery more in-tune with the far more interesting personality of the brewery’s owner.

“Flying Monkeys is a little left of center,” head simian and company president Peter Chiodo told Canadian Packaging magazine during a recent visit to the 9,000-square-foot brewery and its 50 employees. “The brewery name was inspired by a sign I have on my back porch: ‘Don’t make me get out my Flying Monkeys’.

“It is indeed from The Wizard of Oz, which is really a pretty trippy adventure.”

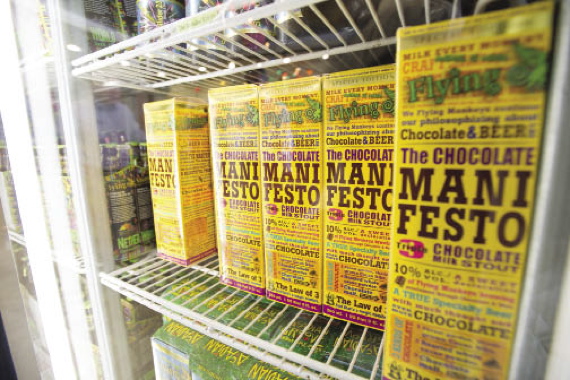

Different in so many ways, the Chocolate Manifesto Triple Chocolate Milk Stout beer bottle of Flying Monkeys comes in its own individual paperboard carton package.

Whether it’s a little left of center or trippy, the independent, locally-owned craft brewery is not one for a ‘normal or straight’ beer, but rather seeks to push the envelope by creating beers with unique flavor profiles that aren’t weird for the sake of being weird but rather are beers with flavors that taste surprisingly good.

With a nod to the more experimental Europeans, Chiodo says, “We make beers you don’t typically get in Canada, flavor-wise. As well, our beers are generally higher-gravity beers, a technique that results in a higher alcohol content.”

Nowadays, the brewery produces 23 brands a year most available only for a certain period of time, including: SuperCollider2.0 Double IPA at 10.4% ABV (alcohol by volume); 12 Minutes to Destiny Hibiscus Pale Lager at 4.1%; Acadian Groove Canadian Maple Porter at 10%; The Chocolate Manifesto Triple Chocolate Milk Stout at 10%; The Matador 2.0: El Toro Bravo Dry Rye Ale (aged on Spanish cedar) at 10.1%; and the six more regular brews that still don’t look or taste like a regular beer—Hoptical Illusion Almost Pale Ale 5%, Netherworld Cascadian Dark Ale 6%, Smashbomb Atomic IPA 6%, Genius of Suburbia 3.8%, Antigravity Light Lager 4% and Flying Monkeys Amber Ale 5%.

As evidenced by the beverage monikers, Flying Monkeys likes to utilize some interesting ingredients in its beer concoctions.

Flying Monkeys utilizes a new NA HMI (human-machine interface) from Omron, part of its Sysmac NJ control system showing Fermenter tanks 11 and 12—the screen allows the operator to view tank temperature, level and various control valves necessary to monitor the fermenting process.

The 12 Minutes To Destiny beer is a pink-tinged ale made from Cascades hops and steeped with hibiscus flowers, fresh raspberries and orange peel, and despite it sounding overly fruity, Chiodo says the hibiscus flower actually adds a tartness to the flavor that makes it all come together into one refreshing beer.

“We actually have an area of our brewery that makes three hectoliters in a test vat where we constantly have several different recipes in various stages of production in an effort to create the next Flying Monkeys taste sensation,” explains Chiodo. “Sometimes it’s magic like with our peppery Matador 2.0 or the sweet Amarillo flavor in the Hoptical Illusion Almost Pale Ale—and then sometimes ingredients you swear should blend together to provide an exquisite taste instead taste like a monkey’s… well, you know.

“But that’s why we enjoy the whole experimentation process here at Flying Monkeys Craft Brewery. It’s tricky, but it’s a lot of fun.”

Flying Monkey president Peter Chiodo (left) and automation specialist Chris Mavreas are very happy with the Omron technology that makes its brewing process more consistent.

Chiodo isn’t your typical Canadian brewer. Although he grew up in Toronto, he is a graduate of the University of Alabama and the University of Mississippi, loves his NCAA football, likes hockey but isn’t fanatical about it. From out of a romance novel he married his college sweetheart, Andrea, who now utilizes her talents and Ph.D in literature to design the fantastic images on the beer bottles and packaging while taking a firm hand in the marketing of the Flying Monkeys beer.

“Andrea has been instrumental in helping Flying Monkeys achieve distribution in the U.S.,” begins Chiodo. “It really is a dream come true for us all to increase our distribution by getting into America.”

Also available at the brewery’s walk-in store located on premises, as well as restaurants and bars throughout the province, Chiodo notes that they are still only producing around 10,000 barrels of Flying Monkeys beer a year, but is always ready to up the program, but not by selling his soul.

“Being a craft brewery is different from being a large brewery,” begins Chiodo. “The big breweries just look at the brand, whereas for craft breweries it’s all about the culture.

“Big breweries have caught onto to that and try to be hip, but it’s a culture you have to live,” he explains. “It’s not about Smashbomb Atomic IPA or Hoptical Illusion Almost Pale Ale—those beers are only part of who we are.

“We’re Flying Monkeys and we’re real people brewing beer and experimenting with crazy ingredients. We’re trial and error—probably lots of error, but that’s who we really are.”

Simply put, Chiodo describes himself as just a normal guy who likes beer and who happens to have got together with some great people to open up a craft brewery.

“But that doesn’t mean we’ll bottle up anything we don’t think people will like,” explains Chiodo. “We know that beer is like art, and it takes into account that people have different tastes, but we are all into pushing the boundaries with our beer flavor profiles.

“Our beer has even been into space,” mentions Chiodo in such a casual manner that one isn’t sure if the easy-going brewer is pulling your leg.

Turns out he wasn’t.

On June 4, 2015, on a homemade platform and balloon holding three GoPro video cameras, back-up battery packs, an altimeter and recovery beacon, Flying Monkeys launched a bottle of SuperCollider2.0 Dry IPA from the brewery’s rooftop up to the boundaries of space.

Using a demonstration box, Omron account manager Ralph Nymann discusses with Flying Monkeys automation specialist Chris Mavreas the basics of how an industrial control system can further increase the craft brewery’s production consistency.

With the beer still liquid at an altitude of 109,780 feet above the Earth, the balloon burst and beer and platform began a controlled decent via parachute. Following the beacon, the Flying Monkeys recovery team drove 116 kilometers over three hours to find it intact in a forested grove.

“We did it to celebrate our 10th year of operation, and because it was something weird that we thought we should do,” states Chiodo, adding, “If we can launch our beer into space, it can’t be as difficult to get our beers into the stores.”

He says that getting his beer into the LCBO (Liquor Control Board of Ontario) stores was a bit of a challenge—something few craft beer companies have managed to do—but it is able to sell six packs of six different beers in over 600 LCBO locations throughout Ontario.

“It’s weird, it doesn’t matter how many awards we’ve won for our beer, but I do understand that the LCBO has limited shelf space and tries to balance out the three categories of spirits, beer and wine,” Chiodo notes. “But the Beer Store is a monopoly.”

The Beer Store is an entity owned by a triumvirate of Labatt (AB InBev), Molson Coors and Sleeman (Sapporo), and Chiodo says that if he wants his beer to be sold there, Flying Monkeys has to pay a listing fee.

“If we were to ship a six-pack, 12-pack and 24-pack to all 440 Beer Stores in the province, it would cost $250,000 in listing fees,” reveals Chiodo. “And while I could afford limited distribution, the returns would not match the investment.

“It turns out space isn’t the final frontier for Flying Monkeys.”

Complaints about distribution aside, Chiodo and the Flying Monkeys team are quite high on a new technology recently purchased.

“We like to have a lot of fun making our beer, but we are very serious about how we create it,” says Chiodo.

“We brew our beers to taste, not necessarily to style, giving plenty of respect to the ever-changing boundaries of the craft brewhouse.”

Omron Automation & Safety, a division of the Japanese Omron Corporation, recently sold Flying Monkeys Brewery an easy-to-use technology that automatically controls the fermenting vat’s temperature along with the analog valves, as well as providing a monitoring of tank levels.

According to Omron Automation And Safety account manager Ralph Nymann, “Over the next few months we are adding more technology to the Flying Monkey’s facility that will include additional control systems for the brewhouse—where the brewmaster controls all aspects of the beer process—as well as the packaging line situated in the facility’s lower level.

“When the project is complete, this will be a self-sustained brewhouse run via programmed recipes.”

The control system being utilized is the Omron Sysmac NJ501 MAC (machine automation controller) with distributed NX I/O, along with—currently—two seven-inch NA HMI (human-machine interface) displays for operator control and guidance.

An additional larger operator screen interface is also being added partially for operator guidance, but also it will be used during the facility tours the brewery does on a daily basis to better explain how the brewing process works.

As Nymann states, future plans will include additional control systems for the brewhouse—which features an additional 70- valves and temperature and level controls, as well as additional drives for motor control—and a system for the brewery’s cleaning process that will include the monitoring of caustic conductivity.

“The next installation phase will also include the ability for Flying Monkeys to connect the Omron Sysmac NJ501 controller via an iPad for remote monitoring and control of the whole brewing process,” notes Nymann.

For Omron, the Sysmac NJ501 MAC is the flagship of the controller lineup.

“It is a freshly redesigned hardware platform containing a powerful Intel Atom processor which has more than proven itself capable of handling harsh and wet work environments,” explains Nymann.

“Because Omron has shifted away from the rigid ASIC-based architecture, it allows the NJ-series to be more adaptable and scalable, providing greater flexibility without compromising the expected Omron reliability or robustness.”

With distribution across North America, ULine’s Toronto office supplies Flying Monkeys with all its stretchwrap needs to safely secure kegs and bottle packs to pallets.

For Chiodo, the ease with which the Sysmac NJ501 controller helps him perform his work is what is key.

“That’s the bottom line, isn’t it,” he grins. “Although we always have someone around watching the brewing process, we are only human—sort of.

“The Sysmac controller we have in place now, and the ones we will have in place shortly will help us create our beer in a more systematic manner ensuring we can provide our customers consistent quality with every batch,” says Chiodo.

According to Omron, the unification of advanced motion control with machine logic in one unit provides machinery with a fantastic advantage as the NJ-series seamlessly combines two prominent application requirements to reduce hardware and development cost.

“The ‘handshaking’ and other intermediate steps needed with multiple systems that create overhead, inefficiency and delay are all eliminated while functionality and performance are increased,” notes Nymann, adding that Omron’s tying in of vision via a built-in EtherCAT interface, configured from the same software environment as the logic and motion, makes the solution unprecedented.

All logic, motion, I/O, and vision response refreshing are all executed in the same control period which sounds like techno babble, but it provides precise sequence and motion control which provides The Flying Monkeys brewmaster with superb control over how the beer is created.

Situated away from the brewing process, Flying Monkeys houses its packaging lines in the basement where it fills barrels and glass bottles.

Flying Monkeys utilizes a Krones labeler to provide quick and neat wraparound labels along the neck and body of its glass bottle packaging.

Along with an automated glass bottle rinser and a Maxima bottler, equipment on the lines includes:

•

a Krones labeler;

•

Arol bottle cap crowner;

•

IDD keg washer;

•

corrugated cartons produced and supplied by Moore Packaging;

•

a Videojet Marsh coder to apply lot code data onto the cartons;

•

ULine stretchwrapping for pallet wrapping;

•

Stainless steel kegs supplied by MicroStar Logistics.

For Chiodo, while fully aware that Flying Monkeys is first and foremost a business, he still insists that everyone involved have fun at work when having fun is appropriate.

“We keep things loose at work, and I think it shows by the large walk-up traffic we generate at the in-brewery shop and for the facility tours we operate,” says Chiodo. “It’s always different.

“There is no end result because we don’t end our results,” sums up Chiodo “We’re always looking to see what strange and wonderful ingredients we can put into the mix to create that next fantastic tasting beer. It’s an artistic canvas, and we’re still painting our craft.

“It’s an exciting time to be a beer aficionado.”

Advertisement