Shapes of things to come

Alanna Fairey

Design & Innovation Sustainability Design ALPHA VFFS Charles Downer & Co. Ltd. GENESYS VFFS V-Shapes V-Shapes S.r.lNew unit dose packaging solution a breakthrough in consumer convenience

Founded in 2018, the Bologna, Italy-based private-held V-Shapes S.r.l has made it their mission to create original solutions for the packaging world, while also leaving a small environmental footprint.

A principle of family-owned Richmond Hill, Ont.-based Charles Downer & Co. Ltd., the board of directors is comprised of highly skilled professionals working in plethora of different sectors in the packaging industry, with expertise ranging from engineering to plastic materials.

In the hopes of creating a breakthrough product that would leave an impression on customers, a new innovative technology had come to life: V-Shapes.

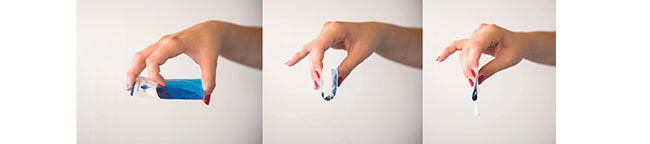

The flip top one hand opening and dispensing system is easy to handle in any situation and is also user-friendly, which is particularly an advantage for elderly and disabled people who have limited function of their hands.

The V-Shapes sachets have a unique flip top one hand opening dispensing system, which offers a unique and outstanding packaging method that stands out from the crowd.

“It’s rare to find something that really makes the difference,” says honorary president Antonio Burattini, who had an impressive resume of 40 years in the packaging industry. “V-Shapes represents one of these rarities.”

Launched worldwide the previous year, the V-Shapes concept helps to bring the one-hand unit dose packaging industry to a ground breaking new level.

Already maintaining a CSA certificate and UL certificates, the plant will soon have their ISO 9001:2015 certification at the machine manufacturing plant in Bologna.

Thanks to the new opening system, customers can make the choice to pack any liquid or granular product with different special applicators.

This unique packaging can be used in a plethora of different industries, which include food, cosmetic, and pharmaceutical, in addition to chemical.

With the one hand opening dispensing system a simple and easy convenience for customers, the V-Shapes packaging comes up with solutions for the unit dose packaging industry that would not be possible with any standard packs already available on the market.

“The V-Shapes packaging is perfect for any company that is thinking of rebranding their product and wants to achieve a high product visibility and good consumer acceptance,” Jeff Downer, chief executive officer of Charles Downer & Co., says.

“Thanks to the new and fresh design, companies can overcome the old-fashioned and bad experience classic sampling packaging solutions, with a new and exciting packaging solution.”

The V-Shape packaging can be produced on two different types of VFFS (vertical-form-fill-seal) packaging machineries, which are both owned and produced by V-Shapes S.r.l at their Bologna headquarters.

The ALPHA VFFS has the capabilities to work with a number of different liquid products, volumes and a range of customizable dimensions available.

The fully automatic VFFS multilane machine includes an accurate servo driven dosing system that prevents costly overfilling on volumes from less than 0.2-ml to more than 25-ml.

Inimitable thanks to its compact footprint, the ALPHA VFFS has an average output speed of 15,000 V-Shapes per hour, showing off its impressive need for speed.

The ALPHA VFFS is not the only machine used to package the V-Shapes sachets.

The ALPHA VFFS is a fully automatic multilane machine, which, along with the GENSYS VFFS, works to package the V-Shapes packets.

Capable to work with many different liquids and granular commodities, the GENESYS VFFS, like the ALPHA VFFS, is a fully automatic multilane machine and has an average output speed of approximately 20,000 V-Shape sachets per hour.

Introduced back in June of 2018, both the ALPHA VFFS and GENSYS VFFS are adaptable to product requirements and also offer minimized production costs.

Both of the V-Shapes machines are also manufactured in accordance with international standards based on GMP (Good Manufacturing Practice).

Thanks to the higher than normal production speed and low manpower and production costs, the V-Shapes sachets promote sustainability thanks to their low environmental footprints.

“Our V-Shapes production process allows to minimize material scrap and we promote an EN 13432 compostable V-Shapes packaging solution for those who have a suitable product,” Downer explains.

“With minimum scrap, low energy consumption, small footprint and V-Shapes Compostable solution we can diminish by 30-percent the environmental footprint in comparison to other packaging companies.”

According to Downer, the V-Shapes sachets are simply a product that will be unlike any other.

Concludes Downer: “Just try it to feel it.”

Advertisement