Home Cooking – Canadian Packaging, June 2014

By Andrew Joseph, Canadian Packaging Features Editor, Photos by Andrew Aleaxnder

Automation Food Safety Cartoning Case Packing Controls/Drives Metal Detection Robotics Ahearn & Soper Inc. Bell-Mark Corporation CHEP Eagle Pack 430 Pro X-Ray Eagle Product Inspection Festo Canada Healthcare Food Services HFS Ilpra Spa Label-Aire LLC Loeb Packaging Limited Markem-Imaje Mettler-Toledo International Inc. Novelis Orion Packaging Systems Plan Automation Pro Mach Industries slideshow Tucs Equipment Inc. Unifiller Systems Wexxar/BEL Winpack Ltd.Ontario food processor cooks up high-quality meals for healthcare facility residents

There’s an old time-tested adage that one can tell plenty about a civilization by the way it treats its sick and elderly.

This wisdom carries even more weight in modern-day Canada, as it is estimated that the so-called Baby Boomer generation that appeared at the conclusion of WWII will, by the year 2015, be senior citizens aged 65 years or older, a point only made troubling by the fact that it is predicted that these elder statesmen will actually outnumber Canada’ youth population aged 14 years of age or younger.

It is thought that by the year 2036, approximately 25 per cent of Canada’s population will be categorized as senior citizens.

Like it or not, there is no escaping the fact that Canada is getting older.

Of course, the silver lining should be the fact that Canadians are living longer due to better overall health, work and living conditions, medicines and even food, though personal choices often play a discriminating role in determining one’s health status and longevity.

Even so, the odds are high that no matter what a person does—regardless of age, sex or creed—there’s a higher likelihood of them having to utilize the services of a hospital to have some illness or debilitation taken care of by healthcare professionals.

(L-R) Brad McKay, Chief Executive Officer, Healthcare Food Services; Rob Brook, Quality Assurance Manager; Stephane Mutchmore, General Manager, Operations.

Golden Age

And even after making it to the golden years, many a senior citizen eventually comes to the conclusion that running their own household is not as much fun as it used to be, and seeks out habitation in a residential care facility where a full-time, on-premises staff ensures its residents are well looked after.

For those requiring a hospital stay and those utilizing the long-term residential care facilities, the need for healthy and nutritious foods is of paramount importance.

And yet, this notion doesn’t always get the respect it deserves.

For many a generation, the term ‘hospital food’ has been a long-standing joke describing some variation of an unappetizing gelatinous mass of greyness that is slopped down in front of a patient.

This shortcoming has prompted many catcalls about how the lack of good food is what drives patients to want to get healthier quicker—to avoid having to choke down any more blandness than they have to.

While that description may be exaggerated, there was—in the past—a modicum of truth to it; a fact that today’s more savvy healthcare facility administrators are all too aware of and eager to make part of the industry’s past.

Taking the reins and leading the way is the food processing business known as Healthcare Food Services (HFS).

Headquartered in the Orleans area of the nation’s capital of Ottawa, HFS is a well-known and respected by healthcare facility administrators as well as a leading expert in the healthcare food industry.

“We offer varied and balanced meals for the people requiring healthcare,” HFS chief executive officer Brad McKay told Canadian Packaging during a recent interview.

“But we ensure that every meal we create is also nutritious and economical.

“It’s all about flexibility and choice,” he adds.

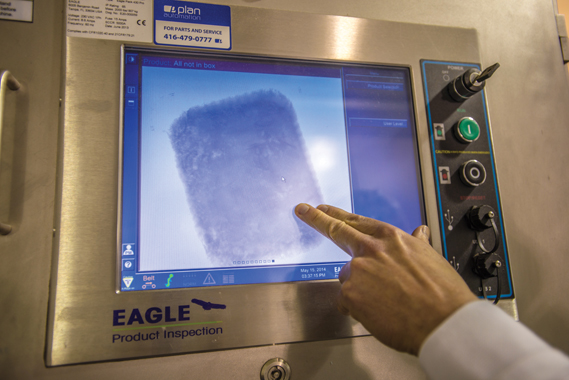

Purchased via PLAN Automation, the easy-to-operate Eagle Pack 430 Pro X-Ray system from Eagle Product Inspection ensures effective product quality control.

More than simply a food processor, McKay says that HFS is a company that was created specifically to cater to the needs of the healthcare industry, noting that “our roots are in healthcare.”

Founded in 1980, HFS was the brainchild of four Ottawa hospitals who wanted to ensure that its patients received a set menu of foods that would provide consumers with eating pleasure during a difficult or stressful time in their lives.

Working out of a 45,000-square-foot production plant, HFS was originally restricted to just serving the Ontario market, actually reached full production capacity in 1999.

But perhaps tired of running at capacity and noting that more and more healthcare facilities were practically begging them to produce food for them, in 2003 HFS took the plunge and constructed a spacious, state-of-the-art, 75,000-square-foot processing and packaging facility, which is 100 per cent nut-free, Halal-certified and HACCP (Hazard Analysis Critical Control Point)-accredited.

HFS prepares millions of meals a year for the healthcare service industry at its 75,000-square-foot, state-of-the-art processing and packaging nut-free and HACCP-certified facility in Ottawa.

Federal Case

The new facility is federally-regulated as a CFIA (Canadian Food Inspection Agency)-inspected plant that allows HFS and its 120 employees to produce and ship foods right across Canada.

No longer limited to only making foods for hospital patients, it has robustly expanded into long-term residential care facilities.

“We go coast-to-coast-to-coast, from the Pacific Ocean to the Atlantic Ocean and all the way north to Baffin Island,” reveals HFS general manager of operations Stephane Mutchmore, adding that while 20 per cent of the company’s business still remains in the Ottawa area, the remaining 80 per cent of its meals are shipped all over Canada.

Thanks to a satisfied customer base, HFS has grown far beyond providing foods for the four parent hospitals in the Ottawa area, now providing millions of meals a year—or, in Mutchmore’s words, “the equivalent of one day’s production would feed one person their dinner for a lifetime.”

By market share, HFS is the Number One dedicated food healthcare manufacturing company in Canada—the key word being ‘dedicated’.

“We do not produce food for any other entity other than healthcare facilities,” says Mutchmore. “We offer a complete menu of single-meal and bulk-meal options, but we are much more than a food processor.

“We see ourselves as a partner who offers our customers more than a list of menu items—we do benchmarking surveys to see how we can best serve not only our healthcare clients, but their patients too,” he explains.

“We will help create a menu that works according to regional and demographic requirements to ensure customer and consumer satisfaction.”

With help from PLAN Automation, HFS purchased an optional product rejection system featuring Festo pneumatics for its Eagle Pack 430 Pro X-Ray unit to help provide greater production line efficiency at its Ottawa-based food processing and packaging facility.

The HFS operation provides what it calls two specific varieties of food items, with 85-per cent frozen, and the remaining 15 per cent chilled, which Mutchmore says is done mostly for transportation purposes.

Running its production 24-hours-a-day, including daily sanitation, HFS produces over 500 SKUs (stock-keeping units), and as Mutchmore notes, it’s often more than simple size variations of products.

A custom-manufactured Label-Aire application system purchased via Ahearn & Soper prints and applies labels with fully-detailed product data onto shipping cartons.

“We actually offer a standard size for most of our products, though each is available as a single meal item or in bulk format, pre-portioned or not, as required,” explains Mutchmore.

“But we also provide modified textures of our products to help consumers who have dysphagia, a condition causing people to suffer extreme difficulty in swallowing foods and liquids.”

Mutchmore says HFS has developed a series of texture-modified foods in three formats: puréed, minced and thickened-liquids, which vary according to viscosity or particle size.

“Regardless of the food or texture, HFS ensures that every product is made with only top-quality, natural, nutritious and flavorful ingredients,” Mutchmore states.

Other special diets offered include: ‘energy-controlled’ for those who need to control their blood-sugar levels; low-sodium, where HFS adjusts spices and seasonings to ensure good flavor; ‘vegetarian’ entrées, soups and sauces that can be made—and coded for ease of consumer distribution—including meatless options without egg or dairy or sans animal protein whatsoever.

HFS produces a diverse list of food products where it considers great taste to be an equal partner of dietary requirements as set up by a facility dietician. These varied product offerings comprise:

•

Breakfasts, offering foods in the continental style or in the classic hot manner;

•

Soups that are Ready-to-serve, requiring nothing to add, mix or dilute, and are conveniently rethermable;

•

Salads featuring pre-washed and peeled top-grade vegetables, which can be prepared to serve alone as a meal or as a compliment to lunch or dinner;

•

Sandwiches, which HFS offers with the option of having wrapped in food-safe packaging to provide freshness and to avoid any possible handling-related contamination;

•

Over 100 entrées featuring beef, poultry, pork, fish and seafood, pastas and meatless all prepared according to regional or cultural food preferences, are preservative-free, and use no artificial flavoring;

•

Sauces and gravies made from scratch via non-powdered mixes made homestyle with real meats and vegetables. These products are prepared as-is—thaw-and-serve—or so that a facility cooking staff may modify it to create a signature sauce or gravy suited to the specific taste and dietary profile of the establishment.

•

Starches and side-dishes—including pasta, rice or potatoes—all prepared so staff can serve easily;

•

Portion-controlled desserts that are all made nut-free and available in a range of low-fat and low-sodium varieties.

• A diverse line of bakery items.

A HFS employee carefully prepares a pallet load of packaged food items on an end-of-line automatic stretchwrapper, manufactured by Orion Packaging Systems, to prevent product shifting during transport to healthcare facilities across Canada.

Party Line

With such a huge line-up of menu items, HFS employs eight different packaging lines: a pumping line, chill, sandwich, bakery, individual meals, portioning line, manual assembly, and slicing.

“Because we are a not-for-profit company, any surpluses are reinvested into the facility to ensure we always have the best production equipment and a smoother and more efficient production line,” explains McKay.

After packing its high-quality, tasty food items for healthcare facilities in corrugated cartons supplied by Loeb Packaging, the cartons are placed upon the signature-blue pallets, manufactured by CHEP and widely used in its pooling program.

A very recent addition to HFS’s capital expenditure is a new Eagle Pack 430 Pro X-Ray food inspection system manufactured by Eagle Product Inspection of Tampa, Fla., but purchased through Canadian packaging system integrators PLAN Automation.

According to HFS quality assurance manager Rob Brooks, the processor was keen on improving its food safety within its production line and specifically wanted to purchase an X-Ray system, deciding a metal detection unit alone would not be able to effectively handle the metal-based packaging used for such items as lasagna.

“Armed with the knowledge that we wanted to purchase an X-Ray system, we visited a packaging trade show, and met up with the folks of PLAN Automation, who were showcasing the Eagle Pack 430 Pro system on behalf of Eagle,” explains Brooks.

Along with being the official Canadian supplier of Eagle Product Inspection X-Ray equipment, PLAN Automation also has an office relatively close to HFS, which was a keen selling point for Brooks.

According to PLAN Automation food safety and product inspection specialist Mat Bédard, “Working with HFS has been a very pleasurable experience right from the very beginning.”

Bédard says that although HFS was quite keen on having an X-Ray system in their production line, they didn’t know much about the Eagle Pack 430 Pro at first.

“In our meetings with them prior to the purchase, we walked HFS through the technology and then we actually asked them to join us at a testing facility in Toronto, where they could see the full ramifications of the Eagle Pack 430 Pro system and how it can provide an extra level of food safety to their program,” explains Bédard.

Brooks recalls, “We were excited by just how sensitive the Eagle system was over some of the other technologies we had seen.”

Bédard says he was actually quite impressed by the thoroughness of HFS, because even after seeing the system, they still wanted to ensure the proof was in the pudding, contacting all of the references PLAN Automation had provided to talk to other Eagle X-Ray system users.

HFS uses a Universal1000i food depositer and filler manufactured by Unifiller Systems to ensure accurate placement of food items into plastic trays.

Armed with rave reviews, HFS purchased the Eagle Pack 430 Pro X-Ray system and after installing it in the summer of 2013, was treated to a thorough training session that showed them how to get the most out of their new food safety machine.

Some features of the Eagle Pack 430 Pro X-Ray system include:

•

High-speed imaging capabilities at a rate of up to 120 meters per minute (400 feet per minute);

•

State-of-the-art, proprietary SimulTask imaging processing software and user interface with improved algorithms for cutting-edge image analysis;

•

A software-enabled ‘auto learn’ function as well as a dynamic belt-speed adjustment that simplifies system set-up to save valuable production time and money;

•

Compact footprint, even though HFS wanted a machine large enough to handle bulk-sized SKUs;

•

Tool-less belt removal;

•

HACCP-ready with full event and contaminant logging.

As a special option on the Eagle Pack 430 Pro, HFS also requested a high-performance reject system featuring pneumatics supplied by Festo.

The Eagle Pack 430 Pro is constructed with glass-beaded stainless steel with a roll-out conveyor, featuring conveyor belting constructed from a seamless impregnated, polyester fiber underside and a white urethane top-face coating formulated to handle a wide product range of temperatures from -30°C to 100°C (-22°F to 212°F).

“PLAN was very amiable in helping us with any after-training questions we had,” notes Brooks, “getting us whatever help we needed right away.”

Adds Bédard, “Simply because we are talking about cabinet X-Ray equipment, the federal and provincial governments require a lot of paperwork to be filed, and that is something we did for HFS well in advance of the delivery of the system to their facility.”

Sealed bulk packs of pork gravy (left) and puréed squash (right) are cooled down in a chilly 2°C cold water bath.

Critical Input

Some of the other critical packaging equipment employed at the HFS facility includes:

•

an Optiform V/G automatic thermoformer, manufactured by Italian manufactures Ilpra Spa, designed for preparation of rigid containers;

•

plastic transparent film for the thermoformer supplied by Winpack;

•

three Markem-Imaje inkjet printers to add lot-code and product identification data to the plastic film packaging;

•

one model TUF-10-25-C bag filler from Tucs Equipment Inc., which supplies the chilled tanks and the inline conveyor used to move packed items from the pump to the chilled tanks;

•

a Bell-Mark EasyPrint S32 direct thermal-transfer printer placed upon the Tucs bag filler;

•

aluminum trays and lids—all lidded by hand—supplied by Novelis, Inc.;

•

An Ilpra 1400N tray-sealer is used for plastic trays and bowls, utilizing lidding film rather than a plastic dome to provide ease-of-use for the healthcare facility during meal preparation;

•

corrugated cartons supplied by Ottawa-based Loeb Packaging Limited;

•

while every carton is hand-packed, HFS uses a Bel 505 case-erector and a Bel 252 carton-sealer, both manufactured by Wexxar/BEL, a Pro Mach Industries division;

•

a custom-built Label-Aire print-and-apply label application system from Ahearn & Soper Inc., a high-performance system that applies labels to the outer side wall of the sealed corrugated cartons delineating product identification in both French and English-languages, product code, lot code, expiry date, case pack number, ingredients and allergen information listed, and a scanable barcode;

•

pallets for transportation supplied by CHEP;

•

pallet-load stretchwrapper manufactured by Orion Packaging Systems;

•

a Universal1000i food depositer and filling machine from Delta, B.C.-based Unifiller Systems;

•

a Mettler Toledo SpeedWeigh weigher to ensure accurate and consistent meal portion control.

A Mettler Toledo SpeedWeigh is used to ensure accurate portion control before moving to an Ilpra 1400N tray-sealer, using lidding film supplied by Winpack (see image below).

Brooks is adamant that food safety is extremely important to HFS, and not merely with its X-Ray system or the way it maintains a clean processing and production line area.

“We generally serve an immune-compromised customer base,” explains Brooks, “so we possess a strong focus on good sanitation and good manufacturing practices to avoid pathogenic and allergenic contamination and cross-contamination.

“We cannot compromise patient safety on our part, so all of our employees watch themselves and each other to ensure we maintain that extremely high-level of food safety,” Brooks states.

From ensuring no employee brings outside food into the production area, to checking that no lock of hair escapes a hairnet, to verifying no sewn-in pockets are worn in case a loose thread falls into the food, HFS is intent on taking food safety to a new level, by removing the risk of any foreign, biological and chemical contaminants into its production line area.

After hand-packing the cartons of food items, Healthcare Food Services uses a high-performance BEL 252 automatic case-sealer equipped with unique Snap Folder capabilities, manufactured by the Wexxar/BEL division of Pro Mach Industries.

Despite HFS being a leader in the market segment, Mutchmore acknowledges that it is rapidly becoming a highly competitive business, with some retail food processors crossing over into the institutional food preparation segment—including some of the biggest food processors in Canada.

“We are now just one of 17 players selling lasagna, for example, to facilities within the healthcare market segment,” reveals Mutchmore.

“And it’s more than just lasagna,” he points out. “Every single category we serve has a major competitor vying for market share also.

“Healthcare facilities should want to work with HFS because we have healthcare in our DNA,” he asserts, “and as specialists in our market, we know our business.”

Mutchmore agrees that in the past some people may have had a negative perception of hospital food.

“But nothing could be farther from the truth,” he states.

“Even though healthcare facilities follow strict nutritional guidelines and dietary practice,” he concludes.

“HFS can easily satisfy those concerns while ensuring the old image remains a thing of the past, as we continue to provide high-quality healthy foods with a high-quality taste.”

Advertisement