RPC turns on the design skills for revolutionary closure

By Canadian Packaging Staff

Design & Innovation Bottling automtive oil packaging bottle closures Flowcontrol bottle innovative packaging lubricating oil closures lubricating oil packaging Millers Oils oil containers RPC Containers UKSC and HalsteadNew five-liter oil pack features unique dispensing closure to easily control flow of oil.

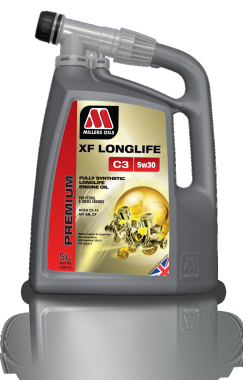

RPC Containers UKSC and Halstead are producing a bespoke five-liter oil pack for leading producer Millers Oils featuring a unique dispensing closure that allows the oil to be fully controllable and to flow freely and easily.

The innovative closure has been jointly designed by RPC and Millers Oils from an original concept devised by Millers to solve a long-standing problem in the market. Lubricating oils have traditionally been very difficult to control during pouring and this often leads to glugging, spills and splashes. The situation has been exacerbated in recent years with the many different oil specifications that are now available.

“This has led to an increase in the use of five-liter containers for each specialist variety rather than larger bulk packs,” explains Millers Oils joint managing director Nevil Hall. “With these different variants, it was necessary to find an on-pack solution that enabled them to be poured easily with no danger of glugging.”

Millers’ solution is a closure incorporating a special valve that twists open and shut to control the flow of the oil. As the oil is dispensed out of the spout, a smaller opening below sucks air back through the closure and into the base of the container. This prevents a vacuum forming to keep the oil flowing freely.

Having developed the concept, Millers worked with RPC to create a suitable container design that could incorporate the new closure. For user convenience a side handle was required, and the pack needed to retain the same height as the previous container in order to run on current filling lines and fit on existing shelves.

The closure itself is injection moulded in PP (Polypropylene) while the container is blow moulded in HDPE (High-density polyethylene) and this created a further challenge in ensuring the two parts could fit together easily.

The resulting Flowcontrol bottle produced by RPC features a ‘straight curved’ shape, where the each curve comes to a defined edge, similar to several latest car designs. This, together with a wide labeling area, helps to create a distinctive presence for the pack on shelf. The handle extends into the distinctive closure on top of the container; the closure itself is produced in a contrasting color to the main pack–a grey bottle with silver closure for Millers Oils’ premium range, and a silver and blue combination for the company’s workshop range.

“This was a major challenge to turn a great concept into a workable container,” says Hall.

“We have been delighted with RPC’s input and their willingness to fully engage in what is for them a relatively small specialist project. The company’s combination of creativity and functional design skills have produced a container that delivers on all levels, while the closure itself is truly revolutionary and has already generated a huge impact among our customers.”

For company information, visit www.rpc-rushden.co.uk.

Advertisement