Home to roost

George Guidoni

Food Safety Robotics X-Ray Automation BRC (British Retail Council) Bridge Machine Company Direct Poultry Eagle 400 RMI Eagle Product Inspection Eagle Repository food safety Fortress Technology Inc. Mepaco North American Meat Association (NAMI) PLAN Automation Inc. POSS Premium Foods Safe Quality Food (SQF) Level 3 certification Simultask PRO imaging software Stein VemagFamily-owned chicken processor keeps spreading its wings in a highly competitive market through proactive investment in advanced food safety systems and technology

A chicken in every pot may have been a luxury for some in days long gone, but with massive advances in farming, processing and packaging technologies since then, enjoying a healthy serving of this exceptionally versatile and nutritious protein has become as routine and commonplace among North American consumers as knocking back a cup of coffee in the morning.

That said, such product availability and ubiquity would never be possible without the enormous and tireless behind-the-scenes efforts by companies like Premium Foods and Direct Poultry to help keep the poultry products supply chain running like clockwork for the consumers’ benefit.

Founded 14 years ago by Augo Pinho, the Toronto-based company specializes in secondary processing of fresh chicken and turkey for customers in the retail, foodservice and industrial market—daily processing thousands of pounds of incoming raw poultry into the more ready-to-cook products ranging from deboned chicken breasts and ground chicken meat, to drumsticks and chicken wings.

“Pretty much whatever the customer specifies: be it fresh, frozen, organic, deboned, MAP (modified atmosphere packaging), IQF (individually quick-frozen) or fully cooked,” says company vice-president Chris Hobbs.

Operating two plants in the northwest Toronto suburb of Etobicoke, the family-owned company has enjoyed steady growth since coming entering the poultry processing industry under the ADP Direct Poultry Ltd. corporate banner—changing its name about a year ago to reflect its diversification into the retail frozen-food product segment and the launch of its flagship Chef’s Kitchen retail brand.

“We also do a lot of co-packing for other food manufacturers,” Hobbs told Canadian Packaging on a recent visit to the company’s second 50,000-square-foot facility started up about four years to accommodate its growing grocery retail business.

Currently employing 190 people at the two plants—also including the original 21,000-square-foot facility a few of city blocks away—Premium Foods runs a busy production schedule to turn out well over 250 different SKUs (stock-keeping units) for its growing client base, now stretching into Western Canada and some select U.S. markets.

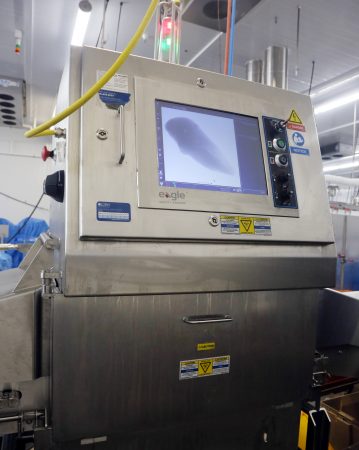

Installed by leading packaging systems integrator PLAN Automation, the Eagle 400 RMI X-Ray system has already resulted in a dramatic reduction of bone complaints among the plant’s customers, while providing a high-accuracy means of detecting other tiny contaminants.

“This newer plant normally operates a two-shift schedule, six-days-per-week,” says Hobbs, who joined the company about two years ago after a long stint in the financial services industry.

As Hobbs relates, the company’s success is rooted in its exceptionally quick turnaround in order fulfillment—especially for smaller businesses finding themselves short of product to put on their store-shelves or menus.

“The company started out on the idea of being a 911 chicken delivery service to help retailers and other customer to overcome temporary inventory shortfalls,” he explains, “and we have the capability to serve them within hours of them placing their order if they are close enough, and certainly within a business day.

“Also, being a federally inspected facility allows us to serve customers right across the country,” Hobbs points out, “as well as export to the U.S. “It’s a key prerequisite for serving the regional distribution centers for major grocers, as well customers in the industrial foodservice sector.”

To achieve this status, the company has worked tirelessly over the years to maintain the highest HACCP (Hazardous Analysis Critical Control Points) food safety standards possible, along with obtaining the internationally recognized food safety certifications from both BRC (British Retail Consortium) and SQF (Safe Quality Food Institute).

Both plants are also fully USDA (U.S. Department of Agriculture)-approved for selling to the U.S. markets, Hobbs points out, and are also fully certified for organic and halal production.

While chicken accounts for 80 per cent of the company production output and turkey for another 15 per cent, Premium Foods is also very competent at processing all the other primary red meat proteins such as lamb, pork and beef to customers’ specifications, according to Hobbs.

“Every meat except seafood,” he states. “Be it a couple of boxes or several truckloads, we are here to serve all our customers, whatever their size.”

To ensure premium quality products, Premium Foods invests considerable capital in new processing machinery and methods, explains Hobbs, citing recent installation of a made-in-Italy Stalam defrosting unit that employs radio frequency (RF) technology to achieve rapid defrosting of bulk meat, rather than microwaving or other conventional techniques.

“This is only the second such system to be installed anywhere in Canada,” sates Hobbs, praising the inline system’s exceptional throughout speed, gentle product handling, and operational flexibility that allows for bulk frozen chicken to be put through the system in the same distribution packaging in which the product had arrived.

“We load it up with meat frozen solid at -18°C and it comes out at the other end 20 minutes later at -2°C, without us even unsealing the boxes,” Hobbs relates. “It has drastically reduced our time requirements for dethawing frozen product.

“Not only is the thawing process more rapid,” Hobbs extols, “but doesn’t cook the meat whatsoever, like a microwave defroster would.”

Line workers at the Premium Foods facility conduct visuual inpection of skinless deboned chicken breast son a high-speed production line that also passes through a recently-installed Eagle 400 RMI X-Ray machine to detect any overlooked bone fragments left inside the meat.

Among other notable capital investments on the processing machinery side, Hobbs proudly points to a new POSS mechanical meat separator, used primarily for making ground and sausage meat; a Mepaco mixer/grinder; a Vemag model HP 25E filler; a two-stage Stein oven; and a high-performance mixer/former from Bridge Machine Company.

A major portion of the meat processed on these machines is quickly shaped into meatballs, sausage, patties, etc., and swiftly conveyed into the adjoining Ready-to-Eat product room for further processing or IQF freezing, as required, and final packaging in bags or boxes.

As required by the company’s food safety requirement, the Ready-to-Cook line is a fully separated climate-controlled room with its own sanitary requirements and procedures.

The spanking clean room houses a couple of recently-installed Vemag pressure cookers purchased to handle the plant’s fast-growing chicken wing business, with Premium Foods recently winning a long-term contract to supply wings to a leading foodservice distributor in Western Canada.

For company founder Pinho, whose 33 years of experience in the poultry business stretch back to his high school days, the company’s promising early growth in the grocery retail segment is immensely gratifying.

“We have been at it for about five years now,” Pinho relates, “and I think that we are now approaching the top of our game.

“There is definitely a learning curve involved in getting used to a new customer base, different people to contact, different ways of doing business, a lot more contracts to renew on year-to-year basis and so on,” Pinho relates.

“But we are now running this business segment at full capacity now,” Pinho points out, “and we are continuously looking for new ways to do thing better and faster.

“I like diversification because there is a lot of innovation that goes into it,” says Pinho, noting the company’s recent name change is a reflection of the more innovative culture that the company is trying to nurture in the workplace.

“We felt it was the right time to differentiate ourselves from being exclusively with raw products, we decided to reinvent ourselves with the name change to reflect that not only do we also do fully cooked product, but product of premium quality.”

The processing area of Premium Foods plant employs a high-capacity POSS mechanical bone separator in the production of its ground chicken meat, which is then used to make meatballs, sausages, patties and other similar products that are quickly cooked on-site and frozen prior to packaging in the adjoining Ready-to-Eat product room.

With Canadian population growth driven in large part by newcomers arriving from overseas, Pinho says that the timing of the company’s entry into the new fully cooked segment could not be better.

“We can do halal, we can do organic, we can do just about anything to tap into these fast-growing ethnic segments where chicken happens to be a very common dish,” he explains.

“We are already thinking about further expansion in the near future by adding another line and even purchasing another facility.”

Pinho says he is immensely proud that his company has never had to deal with a product recall, stressing that food safety is always a paramount priority in all of the company’s operations.

“We always strive to make sure we’re on top of the list when it comes to food safety,” says Hobbs, citing widespread use of the ozonization treatment throughout the facility to kill off pathogens and other potential contaminants.

“In addition to improving food safety, it also improves the product’s shelf-life,” Hobbs points out, adding that the ozonization process enables the product made at the Premium Foods plant to easily meet all the U.S. guidelines for salmonella count ratings.

Naturally, rigorous product inspection is a major part of the company’s uncompromising quality control procedures, as evidenced by strategic deployment of high-quality metal detection systems along four of its production lines—including two high-sensitivity Stealth series metal detectors manufactured by the Toronto-based Fortress Technology Inc.

While the metal detectors have been working as good as promised, Premium Foods recently decided to elevate its food safety credential and track record to the next level by investing in advanced X-Ray technology to enable in-line detection of bone fragments in chicken meat, which conventional metal detection cannot perform.

While the incidence of loose bone bits finding their way inside deboned chicken breasts and other parts was never at a crisis point, the company decided to take a proactive approach to the issue by contacting its longtime business partner and technology supplier PLAN Automation to suggest an optimal solution.

Well familiar with PLAN Automation’s capabilities through earlier installation of the Stealth metal detectors from Fortress, Premium Foods felt that acquiring X-Ray for its busiest production line handling its fastest-moving products (chicken breasts) would quickly pay off in terms of customer goodwill and company reputation.

They were not disappointed, as PLAN Automation quickly suggested the installation of a heavy-duty Eagle 400 RMI (raw meat inspection) X-Ray system manufactured by Eagle Product Inspection LLC of Tampa, Fla.

Skinless deboned chicken breasts that have passed through the Eagle 400 RMI X-Ray product inspection system are placed inside plastic bags and into shipping crates for delivery to the plant’s retail and foodservice customers while still in their optimal fresh state.

Installed about four months ago, the system has already achieved a “dramatic reduction of bone complaints,” according to both Hobbs and Pinho.

“It has provided a very effective means of reducing bone counts,” says Hobbs, praising the system’s super sensitivity levels that allow it to pick up even the tiniest fragments of bone—even those of bones that haven’t yet fully calcified.

“A lot of other companies we compete with still rely primarily on visual inspection by line operators to take care of bone removal, but it’s simply not possible to do it all at high speed with just the

human eye alone,” Hobbs states.

Built specifically for the meat and poultry industries to ensure superior bone and contaminant detection in harsh environment requiring daily sanitation and hygiene procedures, the robust Eagle RMI 400 X-ray inspection machine combines proprietary SimulTask PRO imaging software with a user-friendly touchscreen to enable instant detection of bone, stainless-steel, aluminum, glass and stone particles as little a one-millimeter or better.

Designed to NAMI (North American Meat Institute) standards with hygienic construction and an IP69K rating for optimal protection anginas high-pressure and high-temperature washdowns,

the machine incorporates innovative inclined infeed and outfeed conveyors which eliminate the need for radiation shielding curtains—eliminating product contact and reducing time needed for

sanitation cleaning.

Supplied with a blue homogeneous food-grade urethane non-wicking friction belt, the system’s proprietary Eagle Repository function allows for convenient review of production statistics, the numbers of rejects and saved images, with all thatinformation transferable onto a PC or network for further data analysis, as well as for product traceability purposes.

As Hobbs explains, the Eagle RMI 400 X-ray system’s primary purpose at the plant is that of a “redundancy mechanism” to compensate for whatever bone fragments may have escaped the initial

visual inspection by the line workers deboning the meat.

Also installed by PLAN Automation, the Stealth series metal detection system manufactured by the Toronto-based Fortress Technology Inc. Is one of several key quality control systems used at the Premium Foods plant in Etobicoke to ensure optimal food safety.

“The line operator is still the first line of defense,” he says, “but this is as good a secondary line of defence as it gets.

“With both looking for defects, we are sure to catch them most of the time,” says Hobbs, praising the system’s robust high-speed operation that enables it to inspect up to about a 1,000 kilograms

of chicken part per hour.

“Nothing is bulletproof, but having this highspeed system in place has reduced our bone complaints dramatically,” Hobbs states.

“It essentially eliminates operator error,” adds Mat Bédard, vice-president and product inspection specialist with PLAN Automation in Orangeville, Ont.

“Being able to detect chicken bones of young underdeveloped chickens whose bones haven’t had a chance to fully calcify yet has to be one of the toughest applications in the known X-Raydom,” he chuckles.

“And being able to detect other contaminants in addition to bone is a major benefit to companies like Premium Foods, because in many cases the contaminants originate right at the farm level,” he states.

“For example, free-range chickens are notorious for having a lot of small stones and pebbles being embedded in their flesh, and this system will detect all that.

“Being an organic matter, bone detection is in many ways determined by bone density and shape, so we may be looking at fragment of three or four millimeters in size, which is still quite small,” Bédard explains.

“There is really no such thing as complete guaranteed elimination,” Bédard says, “but if dramatic risk reduction is your goal, this Eagle RMI 400 X-ray as good a

technology as it gets out there in the marketplace.”

Bédard adds that PLAN Automation provides around-the-clock service for all its X-Ray system customers across Canada with a staff of over 40 people—including nine full-time service technicians—as well as an on-hand X-Ray systems inventory worth approximately $350,000.

Adds Pinho: “We train our operators extensively to know here the bones are so that they know where to cut them out, and they are very good at it, but having this second line of defense is critical for us.

“We strive to be the best we can be in all aspects of the poultry business,” Pinho concludes, “and having this advanced X-Ray technology in place is all part of our ongoing drive to succeed in a very competitive marketplace.”

Advertisement