UV curable inks still the big trend

By supplied by Kodak

Automation General Printing Heidelberg KBA KODAK ELECTRA MAX Thermal Plates KODAK SONORA Process Free Plates Kodak UV printing Komori RYOBI MHI Graphic Technology Ltd.While not a new technology, UV’s impact in the printing industry is being felt thanks to lower-energy technologies.

With all the buzz around digital printing over the last decade or so, it’s easy to miss the fact that during that same time span there have been some big changes for offset printing. Approximately 97 percent of printed pages come from offset presses, with only three percent printed digitally, so any changes to offset technology have the potential to make a big impact both for individual printers and for the industry as a whole.

Arguably, the most noticeable change in offset printing technology has been the trend toward UV (ultraviolet) curable inks. UV technology has been used in the printing industry for a long time, particularly with packaging, label, and business forms printers, but it hasn’t had much penetration in other areas until recently. However, in the last few years, UV has taken off among commercial printers, primarily due to new, low-energy UV technologies introduced by the major press manufacturers.

Kodak has been watching the move to UV closely, talking with its customers about the improvements they are seeing in their printing operations with UV, working with them to make the transition as smooth as possible, and developing new products that can extend the advantages of UV for them even further.

Brief Overview of UV Printing

UV curable inks were introduced as an alternative to solvent-based products to provide improved print quality and higher speed to a dry print.

Conventional heat and air drying works by solvent evaporation, a process that shrinks the initial wet coating and additionally can release environmental pollutants when organic solvents are present (VOC’s). In UV curing, there is little or no solvent.

Instead, the inks comprise liquid reactive components.

These reactive components can be hardened rapidly through the application of UV light, which causes chemical crosslinking (or hardening). Because there is little or no solvent to evaporate, there is no volume lost from the wet coating, resulting in higher ink densities and higher gloss on the print. In addition, there are no environmental pollutants from any organic solvents. Through the use of photoinitiators, it has been possible to cure the inks using UV lamps.

Conventional UV lamps consume a lot of power, take up a lot of space and generate a lot of heat.

These systems also produce ozone, requiring an extraction system that adds cost to the press.

Together these factors limit the application to print shops where the value of the print product would pay for the equipment and cost of running the UV. More recently, with the advent of higher powered and cheap UV sources, it has been possible to provide the same amount of energy to the wet sheet but with a lot less power, heat and space, and no need for an ozone extraction system.

With these new low-energy UV systems, such as LED-UV, H-UV, HR-UV, and LEC-UV, equipment and running costs are reduced, and old presses can be more easily modified with the smaller equipment.

These less expensive, smaller systems are allowing commercial printers to use UV and take advantage of faster turnarounds, less maintenance through use of less anti-setoff powder, a wider range of substrates, and higher print quality.

KBA (UK), Ltd. product and marketing manager Craig Bretherton states, “Commercial printers are also being attracted to this technology as it means difficult-to-dry stocks, such as offset, can be quickly turned around without the need for coating. In addition, due to the lack of a requirement for extraction and coating units in many cases, capital costs to add new drying technologies are not prohibitive.”

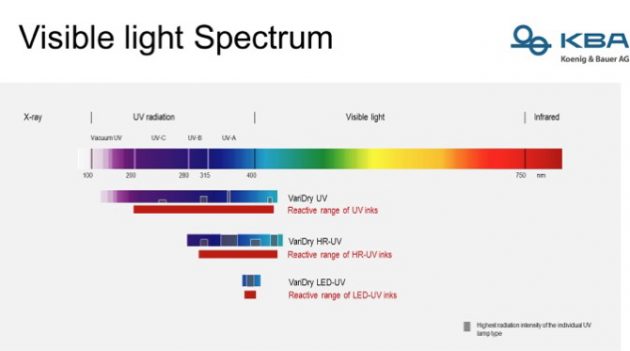

Caption for image: One of the benefits of low-energy UV is that it does not produce ozone. The graphic shows the typical active areas for the various UV options for KBA drying systems. Traditional UV is partially active below 200 nanometers (nm), which is where ozone is produced. HR-UV and LED-UV are not active in this area of the UV spectrum, and therefore do not produce ozone.

Printers in Japan have widely adopted low-energy UV presses, with Ryobi MHI (RMGT) being one of the first press manufacturers to the market with their LED-UV technology, and with Komori offering H-UV technology. Kodak estimates that about 70 percent of new presses made in Japan are now low-energy UV presses. In Europe, UV presses are also dominating new press sales.

Heidelberg estimates that approximately 15 percent of their global installations of presses are UV presses.

New Technology Means More New Technology

Switching to a UV system requires a complete review of all current components that go through the press, and some changes will be necessary. Not only will a printer be changing their inks, they must also look at compatibility with press chemicals, blankets, substrates, and more. In particular, UV can be challenging for printing plates. The good news is that Kodak’s plate scientists and engineers are very familiar with UV technology, and have developed new, innovative plate technology specifically for UV print applications, including low-energy UV.

New plate technologies are necessary because in a UV system, the blanket washes and plate cleaners that are required to clean the special UV-curable inks also happen to be aggressive against the coating of printing plates. Also, as the press chemistries have become more eco-friendly, they provide less protection for the plates. Historically, Kodak provided plates that could be baked to withstand the aggressive chemicals used with UV, but baking is also not very environmentally friendly, using a lot of energy and producing excess heat.

Kodak’s newest plates, such as KODAK ELECTRA MAX Thermal Plates, deliver superior solvent resistance without baking and are therefore ideal for UV applications, plus they require less developer in prepress than previous generation plates, further increasing their environmental benefits. KODAK SONORA Process Free Plates reduce even more environmental impact by eliminating the energy, water, and chemical waste from plate processing. SONORA Plates are suitable for short-run UV print applications, up to 10,000 impressions with SONORA XP Plates and 30,000 impressions with SONORA UV Plates.

What’s in store for the future? We are looking forward to many new innovations around offset print, whether they come from the press manufacturers, other industry suppliers, or printers themselves. And, of course, as the inventor of thermal CTP and the first to introduce a successful process free plate technology, Kodak will be leading the way with new technologies as well.

Advertisement