Smart plastics for Industry 4.0

By Canadian Packaging staff

Automation Controls/Drives Chainflex Motion Cables DryLin linear bearings and linear guides ICOM iglide plastic bushings igubal spherical bearings igus igus communication module Industry 4.0 isense smart plasticsIntelligent cables, cable management, and linear solutions from igus increase plant automation.

igus has introduced an innovative range of “smart plastics” for Industry 4.0 with the goal of making preventative maintenance easier, while reducing costs in the factories of the future.

Nowadays, high-performance plastics are used in moving applications of all types, including medical and lab equipment, bicycles, packaging lines, robotics, machine tools, and crane facilities.

Thanks to decades of testing results, igus is able to make accurate predictions regarding the expected service life of their products in particular applications.

Now, intelligent plastic solutions can ensure additional reliability in factories and applications.

Smart plastics for preventative maintenance

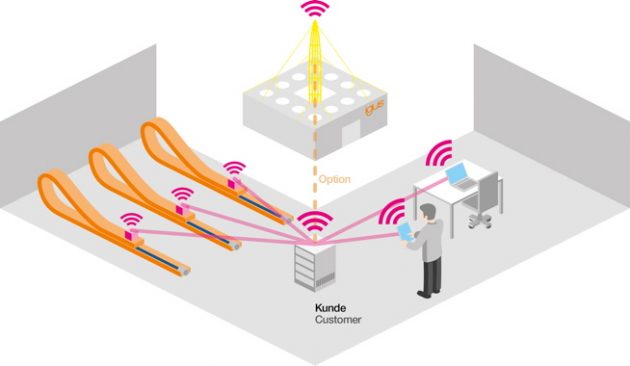

Networked smart plastics, which incorporate a range of sensors and monitoring modules, can expand the possibilities of preventative maintenance and increase uptime and reduce unexpected repairs and maintenance.

Igus, with its intelligent Energy Chain cable management systems DryLin linear solutions, and Chainflex continuous-flex cables that constantly monitor themselves, help provide an early failure warnings to plant supervisors.

This new range of igus products is called “isense”, and has the ability to network with the igus communication module, or ICOM, via a direct integration with the factory/application interface.

Through the “isense” system, intelligent cable carrier systems, cables, and linear guides communicate with factory personnel to inform about potential maintenance dates.

Automated maintenance saves time and money

isense systems are capable of monitoring the service life of the Energy Chain, cable or linear system.

Through continuous distance measurements and calculations of the system’s parameters, as well as test data, it is possible to also reliably predict the functionality of the operation in real-time. If measured values exceed the set parameters, the intelligent isense products indicate the remaining product lifetime, enabling timely maintenance and/or replacement.

When networked with the ICOM system, options such as the direct ordering of spare parts and maintenance commissioning can be scheduled, lowering maintenance time and costs even further.

For more information about how smart plastics can enable preventative maintenance, visit www.igus.eu/smartplastics.

About igus

igus develops industry-leading Energy Chain cable carriers, Chainflex Motion Cables, DryLin linear bearings and linear guides, iglide plastic bushings, and igubal spherical bearings. These seemingly unrelated products are linked together through a belief in making functionally advanced, yet affordable plastic components and assemblies. With plastic bearing experience since 1964, cable carrier experience since 1971 and motion cables since 1989, igus provides the right solution from over 100,000 products available from stock. No minimum order required. For more information, contact igus at 1-800-521-2747 or visit www.igus.com.

Advertisement