Fight The Good Fight – December 2016, Canadian Packaging

By Andrew Joseph Features Editor; Photos by Cole Garside

Automation General Bottling Capmatic Ltd Festo Inc. Inc. JDA Progress Industries Ltd. SICK Ltd. slideshow Vape Brands International Videojet TechnologiesCanadian vape liquid manufacturer boosting its productivity levels to new heights with fully-integrated filling, capping and labeling capabilities

Vape Brands International founder and chief executive officer Beju Lakhani (left) credits Capmatic’s technician Jeffery Vanderckhove (right) for the successful installation of a Capmatic filling-and-capping line at the company’s Mississauga plant.

It’s not quite true that nobody loves a quitter, because the vape industry surely does.

Canada Census calculates that of the approximately 35 million people in Canada, about five million of them are active tobacco smokers who help fuel the $16.86-billion Canadian tobacco industry—putting a lot at stake for companies in the business of helping people quit smoking.

With researchers comparing the addictive quality of tobacco to that of heroin, many people have found the allure of cigarettes a very tough habit to quit.

While some people trying to quit tobacco have been able to do so ‘cold turkey’ via medical aids, or by using nicotine patches and nicotine gum, many have found themselves drawn back into using tobacco products days, weeks and even months later.

“People looking to wean themselves from smoking are now looking to the vaping industry for a success story,” Vape Brands International Inc. chief executive officer and founder Beju Lakhani told Canadian Packaging during a recent visit to the vape e-liquid manufacturer’s new facility in Mississauga, Ont.

While mainstream media describes vaping as a form of electronic cigarette (e-cigs), Lakhani notes, vaping doesn’t even come close to resembling cigarettes.

Vaping involves the inhalation of heated flavored liquid that form a vapor, with Lakhani noting that the liquid may or may not contain nicotine, depending on the vaper’s choice.

When the vapor is exhaled, there is no smoke. It’s all vapor created by the heated liquid—that is often whimsically-scented to add flavor.

“Vaping is a relatively new technology that is considered to be a safe way to help smokers kick the nicotine habit,” relates Lakhani.

Vape Brands International is one of the largest vape e-liquid manufacturers in Canada, producing some 25,000 bottles of vape e-liquid per month, but Lakhani insists the opportunity is there to produce and sell far more than that.

Housed inside a new ISO 8 Cleanroom inside Vape Brands International’s new Mississauga production facility, the fully-integrated filling, and labeling line installed by Capmatic last month has capacity to fill up to 1.2 million bottles per month.

According to Lakhani, the vape industry is growing by leaps and bounds globally—all thanks to the plethora of people who are using vape products to help them quit smoking tobacco.

“Consumers everywhere have accepted the vape industry,” Lakhani states. “They’ve tried the patch and the gum, but they have also heard the testimonials of the many people who have successfully used vaping to help them stop smoking.

“That’s why vaping is a growing industry.”

Lakhani says that within Canada alone, there are around 1,000 shops catering to the vaping industry, with Vape Brands International distributing its e-liquid products to about 540 of them.

Vape Brands International is certainly counting on the trend continuing.

“I would say that since 2015, the vape market has doubled—nearly tripling in size,” says Lakhani. “In the U.S., there are over 6,000 different brands of e-liquid, just to give you a scope of how large and how popular the vape industry has become.”

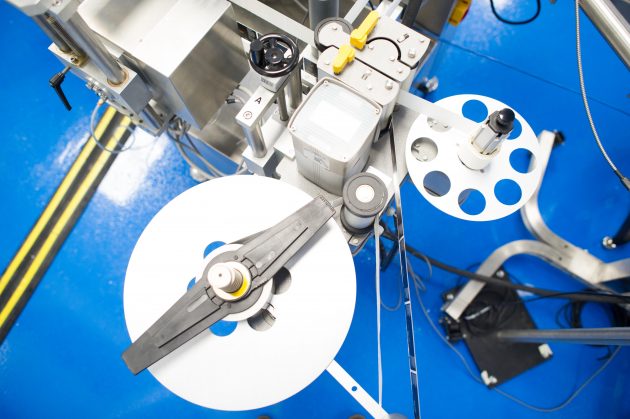

A close-up view of the newly installed CF-2P dual filling component, manufactured by Montreal-based Capmatic, performs precision-filling of 30-ml glass containers of vaping liquid at the new Mississauga headquarters of Vape Brands International.

Vape Brands International was formed in 2013, going live in 2014, producing a single vape e-liquid: Moshi E-Liquid.

Since then, Lakhani and his team have grown the Moshi brand into one of the top-selling vape e-liquids in Canada, with keen penetration into the U.S., European and Asian vape markets.

There’s actually a Moshi Standard and a Moshi Cloud line, with the chief difference being that the Cloud line contains 30 percent more vegetable glycerine, which helps the vaper produce larger bursts of vapor cloud output.

The Moshi Standard line is named after local Toronto-area communities—each with their own distinct flavor

and vibe: Baldwin Village; Black Creek; Bloordale; Centre Island; Chudleigh’s; Danforth; Don Valley; Dovercourt; Dundas Square; Echo Beach; Exhibition; Forest Hill; Fort York; Gladstone; Guildwood; High Park; Kensington; Leslieville; Mimico; Morningside; Mount Pleasant; Old Mill; Ossington; Parkdale; St. Clair; St. Lawrence; Summerhill; Sunnybrook; The Annex; The Beaches; The Junction; Trinity; Union Loop; and Yorkville.

For the Moshi Cloud line-up, Vape Brands International only offers seven flavors: High Park; Leslieville; Rosedale; St. Clair; The Junction; Union Loop; and Yorkville. “We also just released two new brands this past November,” relates Lakhani.

The new Origins line-up consists of three flavors of 30-ml taste: Pomegranate & Kiwi; Aloe; and green Candy Apple. The new Ohana line is currently just one flavor—fruit punch.

“Ohana is the Hawaiian word for ‘family’,” explains Lakhani, whose dad is also involved in the company.

“The brand is our first go at producing our own product in the larger 60-ml bottle, even though we have created product in even larger sizes for other vape manufacturers.”

The Capmatic CF-2P dual filler is capable of filling small glass bottles with vaping liquids at robust throughput rates of up to 60 bottles per minute.

Lakhani says the company is proud to have the full-time services of Andrew Vecchio, to create the recipes for them.

“Before joining Vape Brands International, Andrew was a professional chef for 11 years,” Lakhani reveals.

“His sense of knowing how long various combinations of ingredients need to steep in order to create the final flavor profile we are after, is uncanny.”

A Videojet DataFlex 6420 industrial thermal-transfer printing system performs high-speed application of lot code and best-before-data onto the product labels before they are attached to the vape liquid bottles.

To produce the e-juice, Vape Brands International utilizes hand labor: careful measurement of the ingredients featuring the mixing agents such as a flavorless base or propylene glycol or vegetable glycerine—a concentrate of flavorings for enhanced taste and smell; and if desired by the vaper, various controlled amounts of liquid nicotine.

Each variety of Moshi brand e-juice is available with different amounts of nicotine to help the smoker quit, all the way down to a vape e-liquid containing zero nicotine for those who just enjoy vaping.

After the ingredients are all mixed, steeping is required for anywhere up to a month, depending on the flavor profile or product manufactured, with a daily agitation via bottle shake as part of the plan.

A Videojet 1710 continuous inkjet printer integrated into the new Capmatic packaging line provides Vape Brands International with enhanced product coding capabilities.

“We also have an ultrasonic agitator that we could use to do the same month-long process in just a few hours,” says Lakhani, “but that will come in handy as we get closer to reaching our capacity or if we have an emergency request for product.”

After the e-liquid has been steeped for the requisite amount of time, the plastic jug containing the flavor to be bottled is taken to its packaging room.

Also by hand, in the early days of Vape Brands International, the company then would fill the 30-ml bottles, add a liquid dropper and cap, twist to close, and add a label hoping it was placed perfectly straight.

Manufactured by SICK, the model WL260-R270 photoelectric sensor was installed on the Capmatic line to help ensure precise fill levels for each and every passing container.

“By the end of 2015, it was pretty obvious we had outgrown our 3,500-square-foot facility, so we moved into our new 13,000-square-foot manufacturing center in March of 2016,” explains Lakhani.

At the same time, the manufacturing business began to evolve, “as we outgrew our domestic distribution and established very strong relationships with other vape e-liquid brand owners in an effort to create and expand our international business,” Lakhani notes, adding that in August of 2016 the company launched a private-label business—a brand new direction for the company—as Lakhani has paid close attention to the boom in vape shops opening across Canada and North America.

Thanks to its automated nature, in-house label design with on-site printing, as well as a wide variety of stock bottles and caps, and an uncanny knack to create or recreate customer vape recipes, Vape Brands International has a full-time flavor creation team available to turn ideas into reality.

The new Capmatic filling/capping/sealing system uses compact pneumatic cylinders from Festo to ensure smooth and safe movement for the conveyed glass bottles.

“Having us provide private-label manufacture of vape e-liquid for businesses in California looking to distribute in the east is smart,” suggests Lakhani. “Certain taxes and the cost of transportation can immediately be eliminated when Vape Brands is involved.”

He says that Vape Brands International is already working with partners in several countries “to help facilitate the smooth distribution of vape products in many markets.”

He says the company also has manufacturing partnerships in the U.S., U.K. and China, and can produce and distribute products that meet the challenges of various regulatory requirements. Lakhani says his company represents 15 brands domestically in

Canada, and six brands internationally, “and since all of this business has occurred after a mere three months, you know we are going to continue to grow those numbers.”

After a layer of plastic film is attached to the head and neck area, the bottles are conveyed through a JDA Progress heat tunnel, with a Dayton blower, to have a safety seal applied.

In favor of proper government legislation regarding the manufacture of vape e-liquid products, Lakhani takes a serious role when it comes to product safety.

The new ISO: 9001 facility includes an enclosed 1,600-square-foot ISO 8 Cleanroom and a new filling, labeling, capping line with a safety seal application that gives Vape Brands International the capacity to produce 1.2 million bottles a month, a challenge that Lakhani is more than ready to exceed over next couple of years.

Vape Brands purchased a Capmatic CF-2P dual filling line with a Capmatic Jolly capper, Capmatic LabelStar System 1 ECO labeler, and a Capmatic BandStar 50 safety seal application system, as well as associated conveyors and a rotating accumulation table.

Other equipment purchased through Capmatic includes:

- a Videojet DataFlex 6420 industrial thermal transfer printing system that burns easy-to-read information onto dark surfaces, such as the black labels used by Vape Brands International;

- a heat tunnel manufactured by JDA Progress of Woodbridge, Ont. featuring a Dayton blower that heat seals the plastic film applied over the head and neck of the bottle applied by the Capmatic BandStar 50.

“We only just recently installed the line, and have been working with it on our own since early November 2016,” says Lakhani. “Before that, we had a Capmatic specialist in our facility working with the machine and training us to use it optimally.”

Capmatic calls its automatic CF-2P liquid filler versatile, featuring variable speed control, while being able to dispense and fill liquid or semi viscous products.

“The Capmatic website actually singles out the CF-2P as being the ideal filling equipment for vape e-liquid production,” relates Lakhani.

The CF-2P dual filler—it fills two 30-ml glass bottles at a time from the bottom-up to avoid inclusion of air bubbles—works at a speed of up 60 bottles per minute.

The high-speed Capmatic LabelStar System 1 ECO labeler can apply adhesive labels around each vape liquid bottle at brisk rates of up to 80 bottles per minute.

The new Capmatic line is not truly automatic, as the next phase involves two Vape Brand International employees adding an eyedropper cap to the bottle, and partial twist to close it.

After the line workers place the bottles back onto the conveyor, Festo pneumatics help guide the bottles to the Jolly capper. The capped bottles are positioned accurately within the machine thanks to an indexed starwheel, as the machine tightens the bottle’s cap with a very accurate torque.

Continuing on its path, the bottles pass through the LabelStar System 1 ECO labeler that applies an adhesive label around each bottle up to 80 containers a minute. Just prior to label application, a Videojet DataFlex 6420 industrial thermal transfer printing system

quickly scribes lotcode numbers and best-before date onto each label.

According to Capmatic, the LabelStar System 1 ECO labeler is an economic labeler similar in function and features to the regular System 1 labeler, but operates at a slower speed for less demanding applications like those at Vape Brands International.

The conveyor then moves the bottles individually through the Capmatic BandStar 50 to apply a clear plastic band over the top of each bottle, before it travels through the heat tunnel to provide a safety seal to help prevent product tampering.

A filled, capped and sealed bottle of Moshi Standard E-Liquid High Park flavor atop the line drawing of the recently-installed Capmatic liquid packing line at Vape Brands International.

“While no one likes to think their industry could be the target of product tampering, our company believes it is better to be safer, rather than sorry,” notes Lakhani.

“This is a very competitive industry,” he continues, “and if something negative should occur, we can at least say that we did a good job of protecting our product and the consumer.”

Lakhani says that Vape Brands “puts an emphasis on customer service—it’s more than just manufacturing a product to a customer’s specs; it’s about looking after the customer regardless if they are a liquid brand owner, a retail shop operator or a vape consumer.

“We create a product in a safe manner that ensures the consumer can ultimately enjoy it in safety. It’s why we chose to purchase our line from Capmatic.”

According to Lakhani, he put out a call for submission for a filling line, receiving project quotations from across North America and Europe.

“There were a lot of criteria on our list that we wanted taken care of, and Capmatic was the one company that fulfilled all of our needs on the first presentation,” recalls Lakhani.

Lakhani admits that Capmatic wasn’t the least expensive option presented to Vape Brands, but “price certainly wasn’t everything to us because we are aware that one often gets what one pays for.

“Capmatic’s after-sales service, and knowledgeable history of pharmaceuticals was quite impressive,” reels off Lakhani, adding that the decision was a close one with several excellent companies coming down to the final selection “but what we found, was that we could actually trust Capmatic more than others.

“We just felt that Capmatic would serve us best.”

Captions

The high-speed Capmatic LabelStar System 1 ECO labeler can apply adhesive labels around each vape liquid bottle at brisk rates of up to 80 bottles per minute.

A filled, capped and sealed bottle of Moshi Standard E-Liquid High Park flavor atop the line drawing of the recently-installed Capmatic liquid packing line at Vape Brands International.

Advertisement