Only in Vegas!

Canadian Packaging

Automation Bagging/Weighing Bottles Cartoning Case Packing Coding & Labeling Controls/Drives Conveying Flexibles Motors Printing Robotics Vision PACK EXPO Las Vegas 2019Packaging excellence in full flight at PACK EXPO Las Vegas 2019

Delkor Systems, Inc. is planning to unveil the second generation of its flagship LSP Series robotic case-packer—featuring a scalable, modular frame design to accommodate single, dual or triple robotic loading arms to precisely meet a customer’s production rate up to 120 products per minute. According to Delkor, the new updated LSP case-packer maintains its “unmatched” operational versatility—including vision-based picking and packing of pouches up to 15 pound in weight into Delkor’s popular Cabrio cases, stackable trays, and standard cases with a simple and quick changeover process.

Booth #C-4840

Ryson International will showcase the new Narrow Trak spirals—exceptionally compact vertical conveyors designed to handle small loads at high throughput rates. Capable of running speeds of over 200 feet per minute, the space-saving verticals are equipped with new six- or nine-inches-wide nesting slats which provide an efficient flat conveying surface without gaps to provide reliable end-transfer of small cartons and packages, or side-transfer of small bottles or containers in a single file or in a continuous mass flow. According to Ryson, the Narrow Trak spirals offer an effective alternative to side gripper conveyors because they can run at high speeds and do not need to be adjusted for varying product sizes, while offering generous elevation change capacity. This compact units are equipped with Ryson’s proprietary low-friction chain slat arrangement to ensure assures high capacity, high speed, low energy consumption, low maintenance requirements, and long service life.

Booth #LS-6310

As in the past, Reiser will unveil the company’s extensive portfolio of high-performance food packaging equipment and complete processing-to-packaging solutions in full operational mode—running real or simulated products. The company’s vast equipment solutions on display will include Reiser form/fill/seal packaging machines, Ross tray-sealing equipment, Fabbri automatic stretch film wrappers, Supervac vacuum chamber packaging machines and JLS robotic packaging equipment—all available in various model sizes to meet virtually any production requirement. Among the anticipated highlights, the new Fabbri 75 automatic film stretch wrapper (see picture) will demonstrate the advantages of the innovative four-way stretch technology to produce tight, over-the-flange, wrinkle-free packages of fresh meat, poultry, seafood, and produce in preformed trays at speeds of up to 75 packs per minute.

Booth #LS-6333

B&R Industrial Automation Corp. will exhibit its expansive range of automation technologies designed to support and enhance the performance and flexibility attributes of automated packaging machinery across a broad range of applications, including intelligent track systems; Cloud-based secure machine access; easy-to-use integrated machine vision, and HTML5 human-machine interface (HMI) solutions that work with all the popular PLC (programmable logic controller) brands. According to the company, the new ACOPOStrak intelligent track systems are designed to provide users of fillers, cappers, labelers, cartoners, indexing systems and other packaging equipment with the benefits of true ‘Adaptive Machinery’ to facilitate cost-effective mass customization, while its Cloud-based Asset Performance Monitor application—based on ABB Ability software—automatically calculates KPIs (key performance indicators) such as OEE (overall equipment effectiveness) and machine health to identify opportunities to optimize operation and upgrade assets. For its part, B&R’s new machine vision solution and features a powerful lighting capability and integrates directly into the machine controller and network —rather than a separate vision system—simplified implementation that allows automation engineers to develop a large portion of machine vision applications on their own, with submicrosecond synchronization for increased machine performance and flexibility.

Booth #C-2058

![]()

Leading global industrial instrumentation supplier INFICON is planning to unveil the brand new Contura S600 non-destructive leak detection system featuring and oversized test chamber designed to test products sold for bulk retail and foodservice applications, as well as large-format MAP (modified-atmosphere packaging) and flexible packages. Utilizing a proprietary differential pressure method to detect both gross and fine leaks to offer a faster, easier and quantifiable alternative to methodologies like water baths and gas-based testing, the Contura S600 system’s enlarged test chamber allows manufacturers to test multiple products at the same time, providing a highly efficient testing method for an exceptionally broad variety of foods including pet food, meat and poultry, baked goods, snack foods, confectionery/candy, cheese, grains and cereals, prepared food and produce.

Booth #US-7777

Marking its 50th anniversary this year, Loma Systems will be exhibiting a wide range of inline product inspection equipment to help ensure consumer and safety brand protection within the global food, pharmaceutical and packaging industries, including the new X5C X-ray & CW3 checkweigher combination system. Measuring just 2.5 meters in length, the combination system can easily be integrated where production space is limited by reducing footprint requirements by about 25 per cent, according to the company. The powerful X5C X-ray technology is exceptionally well-suited for accurate detection of all detection of all metal types, glass, calcified bone, rubber and stone in various packaging materials—even for products in foil or metalized film—while the fast and accurate CW3 checkweigher can cope with a wide variety of flexible and rigid packs over a broad range of product weight, while offering

value-added options such as reject confirmation, bin full sensors and infeed guides.

Booth #C-4103

Dynamic Conveyor Corporation will display a broad variety of the company’s conveyor configurations—including the new In-Line Box Filling, Side-by-Side Filling and Over/Under Box filling systems capable of capable of filling by part count, cycle count or weight—designed to ensure exceptionally smooth transfer of boxes from weighing from just a few grams up to 200 pounds in fully-automatic, unattended operation enhance with simple control set-up and an easy-to-read visual indicator. In addition, the company will exhibit its popular DynaCon range of reconfigurable conveyors that allow end-users to easily reconfigure their existing conveyor layouts to suit changing production requirements on demand, similar to the Lego building blocks, with proprietary conveyor modules that include flat, incline, angle and radius turns.

Booth #LS-6317

Domino Amjet, Inc. will exhibit the company’s broad range of the company’s automatic product coding, marking, printing, labeling and stamping systems for product identification and traceability applications in the baking, snack food, dairy, beverage meat, pharmaceutical and other CPG (consumer packaged goods) industries. Among Domino’s most compelling innovations, the new high-speed F720i fiber laser is designed to deliver clear, legible and durable codes on aluminum cans at speeds of up to 600 meters per minute. According to the company, the laser’s unique 3D power concentration can achieves its superior coding quality through use of short and intense coding pulses that significantly increases marking speed and produce a high-resolution mark even on the most challenging surfaces, such as the concave surface on the base of a can.

Booth #C-2437

AstroNova Inc. will exhibit the company’s broad range of tabletop digital label printing solutions, including the Trojan-Label brand the T2-L narrow-format, industrial quality, water-based inkjet press outfitted with lamination capabilities, for enabling seamless print-and-pack with all size print runs in flexible packaging applications.

Booth #C-3906

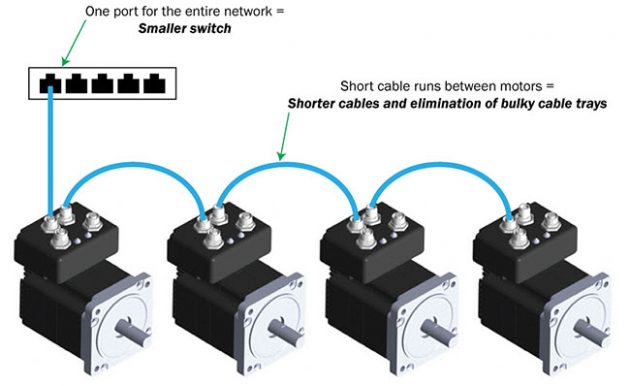

Applied Motion Products will introduce two new NEMA 24 frame integrated motors with dual-port communications for connecting to the industrial Ethernet network of a plant or machine. By incorporating two M12 Ethernet connectors instead of just one on each axis, the SWM24IP-3DE integrated stepper motor and TXM24IP-IDG StepSERVO integrated motor support more efficient network topologies such as line networks and daisychain connections, according to the company, by leveraging the widely used EtherNet/IP network communications protocol to control, configure and query a drive using an open, standards-based, industrial Ethernet connection at speeds

up to 100 MB per second. All of the drive and motor features are accessible over the EtherNet/IP network, including more than 100 commands and 130 registers for controlling motion, I/O, configuration, polling, math, register manipulation, and Q programming. With both motors including a built-in encoder for enhanced positioning capabilities, the SWM24IP-3DE can perform stall detection and stall prevention functions for more reliable and accurate

performance than an open loop motor, and in a broader range of applications, while the TXM24IP-1DG utilizes Applied Motion’s StepSERVO closed-loop stepper technology to improve the performance of the step motor with greater acceleration, increased efficiency and higher accuracy, as well as decreased motor heating and noise.

Booth #C-3614

Bosch Packaging Technology, represented in Canada by Charles Downer & Co. Ltd., is planning to demonstrate its single-source bag-in-box system expertise with a running cracker line from bagmaker and settler to product handling, end-load cartoner and case packer. Intended primarily for companies operating in the bakery and cereal markets, the turnkey solution comprise:

- The Kliklok Interceptor product handling machine that deposits bags directly onto its main conveyor by a bagmaker;

- The mid-range Kliklok MEC end-load cartoner capable of handle a wide range of carton sizes, reaching from a thin pizza boxes to four-inch-thick cake boxes;

- The Elematic 2001 case-packer capable of handling a large selection of primary pack styles, such as flowwraps, cartons, cups and thermoforms—as well as hard-to-handle bags—as speeds of up to 40 cases per minute.

According to product manager Bernhard Vaihinger, “We use a special process that allows carton forming without any pressure on the product to take the strain off the products. With speeds of up to 40 cases per minute at an infeed rate of 600 products, it is one of the fastest and most flexible case-packers on the market.”

Booth #C-2800

Beckhoff Automation LLC is planning to unveil the company’s new cutting-edge eXtended Transport System (XTS) to the North American marketplace as a game-changing “Smart Factory” mechatronic solution that combines the advantages of rotary and linear motion principles into a best-of-breed linear transport system that enables intelligent material flow, exceptional precision, real-time robotics integration, and efficient self-reconfiguration based on lot, recipe or other product specifications. According to the company, the robust XTS solution featuring highly customizable and durable motor modules; mechanical guide rails and wireless movers integrating the necessary power electronics; EtherCAT communication and position measurement in a compact form factor to help reduce machine footprint up to 50 per cent. Supporting installation horizontally, vertically or at angles, the system’s tracks can be combined to dynamically manipulate or transport parts with multiple movers for exceptionally flexible mass production capabilities.

Booth #LS-6149

Wildeck, Inc. is planning to conduct a live demonstration of the company’s industrial elevated mezzanine platforms that can be used for storage, manufacturing, office space or as an equipment access platform. Constructed with heavy-duty steel, these freestanding structures can safely support tremendous loads, including industrial packaging equipment, while offering manufacturing plants a cost-effective way to expand their available production and storage space by simply adding a single- or multi-tiered mezzanine to an existing building.

Booth #US-8420

Conveyor manufacturer Dorner will present its new FlexMove conveyor line that, according to the company, has taken the best attributes of two existing product lines and merged them into a single platform combining the best

engineering and performance standards in flexible conveying automation from both lines, while also simplifying the product category into one universal platform. Available in three purchasing options based on the customer’s applications and situation, these aluminum-frame, flexible-chain FlexMove conveyors are designed to make tight 360° turns in and around machinery and equipment to overcome floorspace limitations and elevation changes across a broad range of packaging, parts handling, product transfer, assembly automation, and machine conveyance applications.

Booth #C-1844

UniTrak Corporation Ltd. will unveil the company’s new KleanTrak series sanitary belt conveyor specifically engineered to overcome the challenges of sanitary conveying with an innovative design that facilitates easy cleaning in food, pharmaceutical and other washdown environments, while also minimizing the potential for bacteria growth. Featuring 304 grade stainless-steel frames and offering a variety of finishes, including electropolishing, the KleanTrak conveyors use a cleated FDA-approved belt in a patented tensionless drive system that ensure no belt slippage or stretch, according to the company.

Booth #LS-5843

Eagle Product Inspection (represented in Canada by PLAN Automation) will display the company’s new high-performance Eagle Pack 240 HC compact XRay machine designed for easy washdowns in harsh environments for packaged meat, poultry, dairy and other food applications where daily sanitization of equipment is mandatory. According to the company, the new machine is engineered to provide superior X-Ray performance in the detection of foreign bodies in several package types, including chubs, overwrapped trays, pouches, cartons, tubs, cups and plastic containers.

Booth #C-1506

Triangle Package Machinery Company’s exhibit will feature the company’s new model CSB (Compact Sanitary Bagger) hygienic vertical from/fill/seal (VFFS) machine capable of running over 70 bags of product—such as fresh-cut produce—per minute. Featuring a narrow film cage that can accommodate up to 27.7-inch rolls of film, the model CSB offers users exceptional flexibility when placed in a side-by-side configuration, whereby they can run varying film structures or rolls, while sharing the same scale for filling the bags. Utilizing Rockwell Automation controls for optimal throughput and performance, the CSB machine offers superior hygienic design features solid stainless-steel bar, fully welded and electropolished after welding; solid round bar stock frame; internally mounted guard doors pivot on the frame; a pivoting control box offers easy accessibility; no slotted fasteners; and washdown-rated electronics

Booth #C-2614

Advertisement