High barrier metalized films and elimination of starry night defects with BOBST DarkNight

By Canadian Packaging staff

Automation Design & Innovation Food Safety Film Bobst DarkNight defect reduction high barrier metalized films K4000 vacuum metalizing platform K5000 vacuum metalizing platformBOBST’s DarkNight is a new approach to high barrier metalization.

New from BOBST, is the DarkNight process that produces high barrier metalized films through defect reduction and web-handling optimization.

Loss of barrier performance due to defects is a common problem

Defects on metalized films lead to a drastic deterioration of barrier properties and poor visuals known in the industry as “Starry Night”. Reduced water vapor and oxygen barrier in turn translate in to a reduction in shelf life of food products.

BOBST DarkNight for higher barrier metalized film

In order to meet the increasingly demanding standards in the flexible packaging industry for barrier applications and products with longer shelf life, BOBST has developed DarkNight, a unique and innovative process to produce High Barrier metalized films through its K5000 and K4000 vacuum metalizing platforms.

Traditionally, thin aluminum foils are used as a barrier in laminate structures to protect products from moisture and oxygen permeation, UV light radiation and aroma/mineral oils migration but leading brand owners now want to reduce their aluminum foil consumption in order to reduce packaging costs but also need a more consistent quality in their supply chain of metalized films.

As BOBST is known in the industry as a process specialist, it was a natural step to use this know-how to develop an innovative solution which is a major step forward in the journey to full aluminum foil replacement.

Cost-effective solution

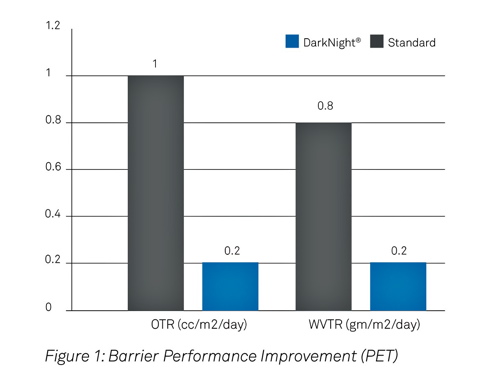

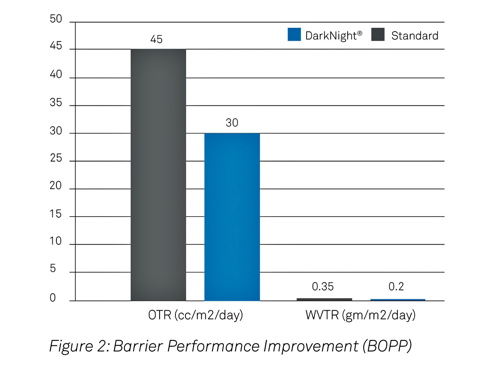

BOBST DarkNight is the smarter way to achieve high barrier metalized films at a lower cost; a major cost advantage arises from the fact that it eliminates the need to use high Optical Density (OD) deposition levels (>3.0 OD) in order to achieve high OTR & WVTR barrier values; as is usually required for high barrier applications.

Superior packaging protection

The BOBST DarkNight process works in conjunction with BOBST Hawkeye (which comes as standard) which along with the Optimized Web-Handling System provides a new approach to defect reduction which enables the production of higher barrier films.

Enhanced barrier performance means superior packaging protection properties (permeation resistance) resulting in increased shelf life for food products; in addition the effective light barrier properties which BOBST DarkNight provides protects products which are particularly sensitive to UV rays.

- 90 percent defect reduction*

- 80 percent barrier improvement*

*actual values largely depends on film properties

Defect reduction, improved barrier and improved visuals

The BOBST DarkNight process provides film producers and converters with three key advantages: defect reduction; improved barrier levels and; improved visual appearance of the film.

BOBST DarkNight results in improvements in both barrier and visual quality of the film.

About BOBST

BOBST is the world’s leading supplier of equipment and services to packaging and label manufacturers in the folding carton, corrugated board and flexible material industries.

Founded in 1890 by Joseph Bobst in Lausanne, Switzerland, BOBST has a presence in more than 50 countries, runs 11 production facilities in eight countries and employs over 5,000 people around the world. The firm consolidated sales of ~CDN $1.793 billion for the year ending December 31, 2013. Company information available at www.bobst.com.

Advertisement