I can see the light!

By Canadian Packaging Staff

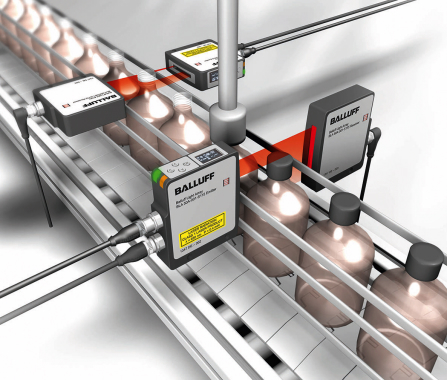

Automation Controls/Drives Balluff Balluff GmbH Balluff Inc. BLA high-resolution light arrayNew high resolution light array from Balluff ideal for applications involving measurement and detection of multiple objects.

Florence, KY—If there is a need to identify different objects during the manufacturing process, packing, or quality control, the new BLA high-resolution light array from Balluff is the ideal solution. This sensor identifies, compares or sorts objects based on minimal size or height differences.

The intuitive nature of the device makes it easy to use. It consists of a powerful red-light laser and a high-resolution CCD receiver and operates completely independently – without any other accessories such as a controller, PC or special software. The Balluff BLA light array has a range of up to two-meters and resolution of 0.01 millimeters.

The multifunctional device offers numerous modes of measurement such as object diameter, object position, gap width, gap position, edge position, etc. In addition, the user can use intuitive, on-device buttons to teach-in up to six different objects and blank out disruptive objects in the measuring field (blanking). Parallel use of the different measuring modes is also possible: e.g., checking the diameter of the object at the same time as determining the position of the object.

In this application, two BLA sensors are used to check whether the bottles in a filling machine have been correctly filled and sealed. The first BLA sensor immediately detects the width of the bottle neck and compares it with previously taught-in values. Once the cap is screwed on, the other BLA sensor checks whether the seal is complete and fits tightly against the bottle.

The BLA is very versatile, even in particularly harsh conditions, thanks to its robust metal housing:

- High-precision position monitoring and detection;

- Quick and easy sorting of parts according to size and/or diameter;

- Quality assurance and monitoring, e.g. of heights of objects, gap sizes, etc.;

- Precise detection of web edges, even with semitransparent materials.

Learn more about Balluff’s BLA light array HERE or watch the YOUTUBE video below:

Balluff Inc., the U.S. subsidiary of Balluff GmbH, Neuhausen, Germany, is a leading manufacturer of a wide range of inductive, photoelectric, vision, capacitive and magnetic sensors as well as linear position transducers, RFID systems, and networking products. Balluff products for OEM and factory floor solutions are used to control, regulate, automate, assemble, position, and monitor manufacturing, assembly, and packaging sequences for industries including: metalworking, automotive, plastics, material handling, wood processing, aerospace, alternative energy, medical, electrical, and electronics.

Questions? In Canada, contact Stephanie Vista, marketing specialist at 1-800-927-9654 or via e-mail at balluff.canada@balluff.ca or visit www.balluff.com.

Advertisement