Understanding Recycled Content

By PPEC - Paper & Paperboard Packaging Environmental Council

General Sustainability Corrugated Paperboard Packaging Containerboard corrugated packaging International Standards Organisation Iso kraft paper Paper & Paperboard Packaging Environmental Council PPEC recycled boxboard recycled paper recycled paperboardWhite paper prepared by PPEC (Paper & Paperboard Packaging Environmental Council) describing how recycled content is defined and measured, how it differs between packaging types, and its relationship to virgin material - all in its Understanding Recycled Content report.

How do we define recycled content?

Recycled content is generally defined in two ways: pre-consumer and post-consumer. Both are recognized by the International Standards Organisation (ISO) and by Canada’s “Guidelines” for environmental labeling. PPEC does not distinguish between the two in its survey results because both divert used paper material for further recycling.

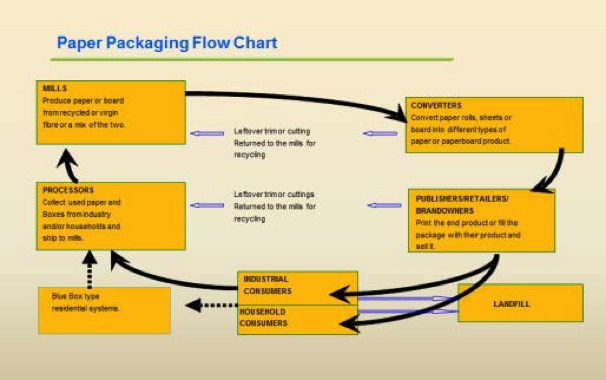

“Pre-consumer” recycled content includes the corrugated clippings or boxboard trim that is left over when converting board or paper into a box, bag, or carton. This leftover trim is sent from the converting facility (box plant) back to the mill for recycling. “Post-consumer” material, on the other hand, is the formed box, bag, or carton that’s sent for recycling after use by industrial, commercial, institutional, or residential consumers.

Some people argue that post-consumer material is somehow environmentally superior to “pre-consumer” material. PPEC (and ISO) do not support this argument. The amount of trim or cuttings (pre-consumer material) at a box plant, for example, is actually relatively small because maximizing the use of the whole board that has already been paid for is in the best interests of the plant and its customer. The next customer will get some of this trim in the next piece of board purchased, and so on in a continuous recycling loop, so the brandowner or retailer should get credit for this recycled content, in our view.

Some people argue that post-consumer material is somehow environmentally superior to “pre-consumer” material. PPEC (and ISO) do not support this argument. The amount of trim or cuttings (pre-consumer material) at a box plant, for example, is actually relatively small because maximizing the use of the whole board that has already been paid for is in the best interests of the plant and its customer. The next customer will get some of this trim in the next piece of board purchased, and so on in a continuous recycling loop, so the brandowner or retailer should get credit for this recycled content, in our view.

There is a further argument for including some recognition of this trim or cuttings sent back to the mill from the box plant. And that is that, generally speaking, a mill needs an additional 10 tonnes of used paper or board to produce 100 tonnes of recycled product shipped out the door. This is because paper fibers shrink in the pulping process. Even though a mill has paid a municipality, a processor, or a broker for 110 tonnes, and technically re-pulped 110 tonnes, it makes no claim for recycling more than 100 tonnes for recycled content purposes. It does not seem unreasonable in this light, to claim trim and cuttings as a trade-off for the shrinkage that is not claimed.

How is recycled content measured?

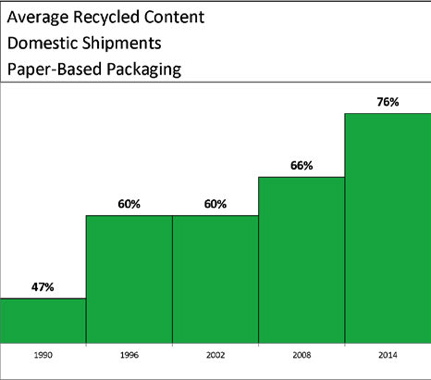

Recycled content is usually expressed as an average. This could be an average of a mill’s particular production run (so each customer can label the recycled content of its packaging) or an average over a much longer period of time (normally 12 months for mill or industry averages). National average recycled content percentages are determined by dividing the number of tonnes shipped by the number of tonnes of recycled paper or board used in those shipments. For example, in 2014, of the 1,565,256 tonnes of paper packaging material shipped domestically in Canada some 1,187,811 tonnes comprised recycled paper or board (giving an average recycled content of 75.9%).

What is the average recycled content of paper packaging made in Canada?

The combined average recycled content of domestic shipments of the three major packaging grades (containerboard, boxboard and kraft papers) as noted above, was 75.9% in 2014. This is very close to our 2012 survey results (76.4%). The average has steadily increased from 47% back in 1990 to close to 80% today.

What is the average recycled content of the various packaging grades?

Kraft paper is predominantly used to make multi-wall sacks and grocery bags.

For this you need strong paper fibers (kraft is the German word for strong). Paper bags in Canada are mostly made from woodchips and sawmill residues left over from lumber operations. Nothing is wasted. Even rotten, bent, or twisted saw logs are salvaged and used. In 2014, one Canadian mill used mostly old corrugated boxes collected from supermarkets and factories or from curbside (what the industry calls recycled pulp) to make bag material, but it has since closed. The average recycled content of kraft paper packaging shipped domestically in 2014 was 32 per cent.

Paper bags collected from household Blue Box-type systems are normally recycled back into new corrugated boxes rather than separated out and shipped back thousands of kilometers to the nearest kraft paper mill for recycling. For more specific environmental information on paper bags go to www.paperbagscanada.org.

Boxboard, which is used to make cereal or shoe boxes, does not require the strong paper fibers that kraft paper bags do, and so is mostly 100% recycled content when it leaves the mill. It’s made from a mixture of old corrugated boxes, old newspapers, used printing and writing paper and old boxboard itself, the residential collection of which PPEC pioneered back in the early 1990s.

Of the nine mills in Canada producing boxboard grades in 2014; six used 100% recycled content. Two mills used a blend of recycled and sawmill residues, and one used 100% sawmill residues or virgin fiber. Overall, the average recycled content for domestic shipments of boxboard was 73 per cent. For more specific environmental information on boxboard go to www.paperboxescanada.org.

Containerboard is used to make the corrugated boxes commonly used to ship heavier products.

It too is mostly 100% recycled content. Of the 11 containerboard mills in the country in 2014, seven produced 100% recycled content, and the balance a blend of recycled and sawmill residues or virgin fiber for an overall industry average of 80% recycled content. For more specific environmental information on corrugated boxes go to www.corrugatedboxescanada.org.

Does using recycled content mean that less virgin material will be consumed?

Yes. In the paper industry, however, this fact comes with some caveats. The industry cannot exist without the introduction of virgin fiber at some point in the paper life cycle. It needs longer virgin fibers to replenish the shorter and thinner fibers that gradually wear out as a result of repeated recycling.

Yes. In the paper industry, however, this fact comes with some caveats. The industry cannot exist without the introduction of virgin fiber at some point in the paper life cycle. It needs longer virgin fibers to replenish the shorter and thinner fibers that gradually wear out as a result of repeated recycling.

Paper fibers can generally be recycled between four and nine times. In other words, to keep the whole recycling loop going (and to produce recycled content in the first place), we have to have trees or wood chips and sawmill residues somewhere in the system on a regular basis.

What problems do setting minimum recycled content levels cause?

While it may seem like the “right” thing to do environmentally, the unfortunate reality is that governments and individual companies tend to act in isolation, setting unscientific and competing minimums that suit their perceived (and sometimes narrow) needs. The nightmare scenario for the industry is widely divergent thresholds that bear no relationship to the global supply and demand for paper fiber (both virgin and recycled), and a tendency, driven by politics and public relations more than anything else, to leapfrog over someone else’s number.

If the ultimate goal is to achieve a global balance in the use of the world’s forest resources, isn’t it better to allow countries that no longer have sustainable forests of their own (and there are many), to import their needed virgin material from countries (like Canada) that do have sustainable forests, to keep the whole global paper life cycle going? A couple of the tools to do this are bans on illegal logging and independent third-party certification of sustainably managed forests. PPEC is proud to say that there is no illegal logging in Canada, and that every single one of our mill member companies has achieved what’s called independent “chain-of-custody” certification, or responsible sourcing of raw materials, whether recycled or virgin.

We also question whether, in fact, there is really a need for recycled content minimums for paper packaging in Canada. The overall average is already 76 per cent, far higher than any other packaging material has achieved. And the overwhelming majority of Canada’s packaging mills are already at 100% recycled content. There is not much more the industry can do.

And then there are imports of packaging board and converted boxes, bags and cartons.

Almost half of the paper packaging that Canadians use is imported, either as raw material or as converted product. Any minimum recycled content levels would have to apply equally to imports to meet fair trade rules and various treaty obligations.

Another argument often advanced for setting minimum recycled content levels is that such “green procurement” grows or encourages markets for recycled materials. This is demonstrably untrue for used paper packaging in Canada.

The markets for old corrugated and boxboard are now very mature. Virtually all Canadians now have access to the recycling of these materials and a recent PPEC survey indicated an actual residential capture rate of 65%, over and above what we estimate to be an 85% industrial capture rate for old corrugated boxes nationally. Setting higher recycled content levels than currently being achieved would simply mean that mills would import more used paper and board to meet the minimum thresholds. Capture in Canada itself would be unlikely to increase.

A better and more practical option, in our view, is to ban recyclable paper materials from disposal. In fact, PPEC is calling on provinces to do just that, to ban the disposal of old corrugated containers (used corrugated boxes) from private and public sector landfills.

Environmentally, it is the right thing to do (reducing methane and carbon dioxide emissions). Material bans also extend the life of landfills (delaying costly measures to find sites for new ones). And there are also significant operational cost savings to be gained from bans. No good box should go to the dump.

Environmentally, it is the right thing to do (reducing methane and carbon dioxide emissions). Material bans also extend the life of landfills (delaying costly measures to find sites for new ones). And there are also significant operational cost savings to be gained from bans. No good box should go to the dump.

For more information, contact PPEC at www.ppec-paper.com.

Advertisement