Plastic packaging industry overview and forecast

By Anwesha Majumder

General Bottles Cans Film Flexibles Plastic Department of Environmental Conservation of New York City Flexible Packaging Association Grocery Manufacturers Association Manufacturers Alliance for Productivity and Innovation MarketsandMarkets Natural Resources Defense Council plastic packaging industry forecast Robbie Fantastic Flexibles United Nations Industrial Development OrganizationOverview compiled by MarketsandMarkets provides look at the status of the plastic packaging market.

Packaging trends evolve as per consumer fit, production, and storage needs. The change in consumer demand patterns is the most influencing factor transforming the packaging industry. Plastic has secured its position as the most preferred material in the packaging industry for the sectors such as FMCG (Fast Moving Consumer Goods), food and beverage, pharmaceutical, as well as industrial goods. A large portion of day-to-day household products are packaged in plastics. The extensive use of plastics for packaging can be attributed to innovative visual appeal and convenience. In addition to that, the ability to improve the hygiene quotient and shelf-life of products, especially in the food and beverages segment, is adding to the popularity of plastic packaging.

The packaging industry has been witnessing growth due to factors such as increase in income levels, rising population, and changing lifestyles. Growth prospects of end-use sectors such as food & beverages, pharmaceutical, electronics, personal care, and other FMCG industries are stimulating the rise in the demand for the plastic packaging industry. Organized retail and development of the e-commerce industry are further expanding the demand for plastics for packaging applications.

The period from 1970 to 1980 was known as the “plastic revolution.” Plastic, being lightweight and easily transportable, was used extensively in the packaging of products. The modern packaging industry is under a lot of pressure to constantly advance, meet new environmental standards, and produce raw materials that are more reliable and effective than their predecessors. The increase in demand for packaged food & beverage as well as pharmaceutical products which require protection against moisture and other environmental changes are the major drivers fueling the growth of the plastic packaging market.

Primary Types of Plastic Packaging

The use of plastic in packaging can be primarily categorized into two significant types, namely, rigid packaging and flexible packaging. Rigid plastic packaging is defined as any plastic package having a relatively inflexible shape or form, with a minimum capacity of eight fluid ounces, which makes it capable of maintaining its shape. Rigid plastic packaging is the aggregation of products such as HDPE (High-density polyethylene) bottles, PET (Polyethylene terephthalate) bottles, jars, specialty cosmetic containers, and thin wall plastic containers. Wherein, flexible plastic packaging is a type of packaging that is made of conforming materials or easily yielding materials such as films, sheets, and foils. These materials form flexible bags, pouches, wraps, and sachets that acquire a bendable shape.

In comparison with rigid packaging, flexible packaging is a more dynamic technology and anticipates a strong growth in the future. A gradual shift has been witnessed in the plastic packaging industry from traditional rigid packaging to flexible packaging due to several advantages offered by flexible packaging such as convenience of handling and disposal, and savings in transportation costs as a result of minimal space requirement. Also, flexible packaging is lighter in weight, cost-efficient, and uses less material as compared to other forms of packaging.

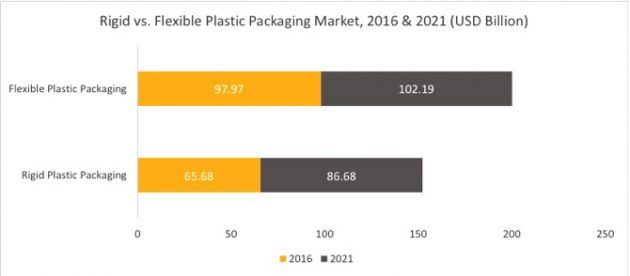

MarketsandMarkets estimated the Rigid and Flexible Plastic Packaging Markets at USD 65.68 billion and USD 97.97 Billion, respectively, in 2016.

Source: MarketsandMarkets Analysis

Market Trends in the Plastic Packaging Industry

Flexible Packaging, Substitution of Traditional Packaging: The growth in the demand for flexible plastic packaging has been driven by the increasing need of replacing traditional packaging materials such as metal cans, glass and plastic bottles, and liquid cartons across a wide range of end-use sectors. Various brand owners started valuing flexible plastic packaging for its flexibility, proportional low cost, and high potential for innovations. The implementation of various manufacturing methods and polymer additions provide the means to increase their appeal to a broad spectrum of products.

Convenience features such as single-serve portions, portability, and easy-to-peel provided by flexible plastic packaging shift the consumer’s focus from rigid to flexible plastic packaging.

Technological Advancements: The invention of flexible films has propelled the plastic packaging industry has been to remarkable heights. Through the development and utilization of these films, manufacturing practices, and continual innovations in the packaging technologies such as Modified Atmosphere Packaging (MAP) and Vacuum Packaging, the field of packaging has been able to grow and advance to adapt to the needs of products across the globe. Flexible plastic packaging solutions help reduce the carbon footprint. This favorable environmental impact translates into high-growth prospects for the sector. Nanotechnology greatly influences the packaging sector. It is also used to enhance the barrier properties of flexible plastic packaging. Continuous development and innovations in the packaging industry will offer immense opportunities for the growth of the flexible plastic packaging market.

Recyclability: The trend of recycling and reuse of plastics is an important step toward endorsing innovation and sustainability. Regulations formulated by governments of respective countries and growing awareness about recycling and disposal of plastic waste are encouraging the packaging industry to develop eco-friendly production technologies and sustainable packaging products.

Increased Food Safety, Quality, and Shelf Life: Plastics offer excellent barrier to oxygen, carbon dioxide, and water, are inert toward acids, alkalis, and other solvents, thus ensuring freshness and hygiene of the contents for a longer period. Plastic packs help in protecting the quality of food items and can reduce the post-harvest losses significantly. According to the Natural Resources Defense Council—a New York City-based, non-profit international environmental advocacy group—up to 40 percent of food in the U.S. was wasted, in 2016. Flexible plastic packaging has been proven to be a superior alternative to enhance the shelf-life of perishable items. For instance, studies show that bananas packaged in flexible plastic packaging have slowed the ripening process and prolonged the shelf-life.

Flexible Packaging is gaining traction due to cost-effectiveness: Due to busy lifestyles, the demand for convenient products has increased, which has led to a rise in demand for flexible packs. Flexible plastic packaging requires fewer resources and energy for packaging; hence, flexible packs are available at low costs and occupy 35 percent less retail shelf space, rendering them cost-effective as compared to other forms of packaging. Robbie Fantastic Flexibles (U.S.), a member of the Flexible Packaging Association (U.S.), states that the manufacturing of 780,000 flexible pouches consumes 87 percent less coal, 74 percent less natural gas, and 64 percent less crude oil in comparison to the manufacturing of rigid clamshell packages. This type of packaging has the ability to package the product in the least packaging possible, thereby lowering product warehousing and shipping expenses while maintaining or improving product protection.

Downsizing of Packaging: Sustainability is closely associated with the reduction of sources used in packaging of a particular product. This reduces the waste generated due to packaging materials. It is related to reducing the volume usage of primary materials in the initial production process by using an ideal combination of primary, secondary, and/or tertiary materials.

Manufacturers have been concentrating on reducing the packaging size and weight, by using fewer materials. According to the Grocery Manufacturers Association (GMA), between 2005 and 2010, its members cut packaging weight by 1.5 billion pounds. The association expected its members to reduce packaging weight by another 2.5 billion pounds between 2011 and 2020. This trend of downsizing packaging helps reduce waste generated out of packaging. The Department of Environmental Conservation of New York City, under its packaging reduction guidelines, states to use a poly wrap or shrink wrap over box packaging to reduce packaging size and bag packaging.

With the development of new technologies, reduction in the amount of packaging by developing lightweight packaging from materials such as plastic films has been encouraging the packaging industry toward sustainable packaging. This is likely to support the demand for flexible plastic packaging as it requires fewer resources to pack the product and at the same time ensures its quality and safety.

Future Opportunities

In the future, the growth of the plastic packaging industry is expected to be majorly influenced by the end-use sectors, government initiatives, and growing consumerism.

After witnessing a downward trend during the recession period, the global manufacturing industry is likely to witness steady growth in the coming years. According to the United Nations Industrial Development Organization (UNIDO), the global manufacturing production increased by 2.3 percent in 2014, representing a marginal change as compared to 2013. The global manufacturing industry will be primarily supported by the growing industrialization and consumption level in emerging economies such as India, China, and Brazil. Furthermore, steady improvement in the global economy is also expected to increase the global manufacturing activities in industries such as food and beverages, healthcare, and cosmetics and toiletries, which in turn will benefit the overall packaging industry as well as the plastic packaging market.

According to the Manufacturers Alliance for Productivity and Innovation, manufacturing production in the U.S. was forecast to post a growth of 4.0 percent in 2016, and 3.1 percent in 2017, as a result of the recovery in the U.S. economy. The Mexican manufacturing output also increased by 3.2 percent in the first quarter of 2015. Continuous expansion of production is expected to drive the demand for both rigid and flexible plastic packaging, which will protect products from damages during storage and transportation.

Growing consumerism will also contribute to the growing demand for plastic packaging. The inclination toward the use of convenient and affordable packaging is driving the market towards flexible packaging, globally. The shifting interest of consumers toward easy handling, long-lasting, and easy-to-store products has created huge opportunities for plastic packaging due to the versatility offered by plastic materials. This growth will also be pushed by the increasing size of the middle-class population in the emerging economies of Asia Pacific, the Middle East, and South America.

In addition to this, plastics are considered to be harmful to the environment, thus several nations have imposed ban on plastic products. The need of the hour is to come up with a sustainable solution by adoption of technologies, upcoming innovations, and eco-friendly alternatives. An integrated development addressing cost-effective processing of plastic, besides streamlining operations of plastic recycling could pave a path for the advancement of this industry.

MarketsandMarkets

MarketsandMarkets provides quantified B2B research on 30,000 high-growth niche opportunities/threats that will impact 70–80 percent of companies’ revenues worldwide. The company currently caters to 5,000 customers worldwide including 80 percent of global Fortune 1000 companies.

Author Bio

Anwesha Majumder has completed post graduation in MBA (Marketing & Operations) from ICFAI with extensive market research, consulting and process automation experience for three years. At MarketsandMarkets and working as a senior research analyst, she executed more than 15 consulting projects in the field of different types of packaging and packaging automation, including those on aseptic packaging, modified atmosphere packaging, laminated packaging in North America, European sterile medical packaging, form-fill-seal packaging, corrugated packaging in the Middle East and Africa, rigid plastic packaging, and Asia-Pacific industrial packaging.

Anwesha Majumder has completed post graduation in MBA (Marketing & Operations) from ICFAI with extensive market research, consulting and process automation experience for three years. At MarketsandMarkets and working as a senior research analyst, she executed more than 15 consulting projects in the field of different types of packaging and packaging automation, including those on aseptic packaging, modified atmosphere packaging, laminated packaging in North America, European sterile medical packaging, form-fill-seal packaging, corrugated packaging in the Middle East and Africa, rigid plastic packaging, and Asia-Pacific industrial packaging.

Advertisement