Three Times The Charm — October 2016, Canadian Packaging

By George Guidoni, Editor; Photos by Cole Garside

Automation Bottling Alliance Packaging Baldor Electric Company Cactus Design Cameron’s Brewing Company Crown Metal Packaging Domino Printing Systems Omron Automation & Safety Palmer Canning Systems Sealed Air Diversey Care Shipmaster Containerboard Ltd. slideshow Tapp Label Company Zebra Paper ConvertersOntario craft brewer catches lightning in a can with classy packaging redesign and a smooth canning line startup

If good things come to those who wait, then Cameron’s Brewing Company provides a compelling example of why patience is a blessed virtue in Canada’s fast-growing craft beer business.

Founded 19 years ago by Cameron Howe in Mississauga, Ont., the privately-owned microbrewer is hardly a newcomer to the burgeoning craft beer market—having been honored with well over 140 prestigious awards for its craft-brewed recipes over the years at dozens of international beer industry competitions.

Cameron’s Brewing Company president Bill Coleman (left) and brewmaster Jason Britton showing off some of the newly-designed packaging for its core and seasonal brands.

But after six years of fine-tuning its brewing competencies at its current digs in Oakville, Ont., under the watchful eye of current co-owner and president Bill Coleman, the company has really come into its own this year as a serious player with a fresh packaging redesign of its core product portfolio and installation of a brand new canning line to fuel a spectacular sales surge across Ontario.

“Our sales have grown by 300 per cent since we launched the new cans earlier this year,” Coleman told Canadian Packaging on a recent visit to the company’s fully-owned, 30,000-square-foot facility that offers plenty of extra room and capacity for what is expected to be a vastly accelerated growth curve for Cameron’s three core flagship brands in coming years.

Toronto-based boutique design agency Cactus Design helped Cameron’s Brewing to modernize its can packaging graphics with an updated company logo and engaging imagery.

With the province of Ontario finally relaxing its long-time ban on retail beer sales outside the traditional LCBO (Liquor Control Board of Ontario) and The Beer Store outlets by letting select grocery chains and independents to sell limited quantities of beer to consumers while they do their regular grocery shopping, Coleman is highly upbeat about the company’s future growth prospects and opportunities.

“Our main beer brands have remained unchanged because we always produced a great beer,” says Coleman, “but our new packaging is

a real game-changer for our overall branding strategy.”

With cans now accounting for over half of all beer sales across Canada, Coleman says that switching the main Cameron’s brands from bottles to cans was always in the cards, but not before the company had the perfectly updated designs to launch into a marketplace already brimming with a growing variety of eye-catching product labeling and packaging savvy.

To achieve the desired high-impact shelf presence, Cameron’s hooked up with Toronto-based boutique graphic design agency Cactus Design, giving it full creative license for a radical rebranding of its mainstay Captain’s Log Lager, Ambear Red Ale and Cosmic Cream Ale varieties, along with several seasonal products.

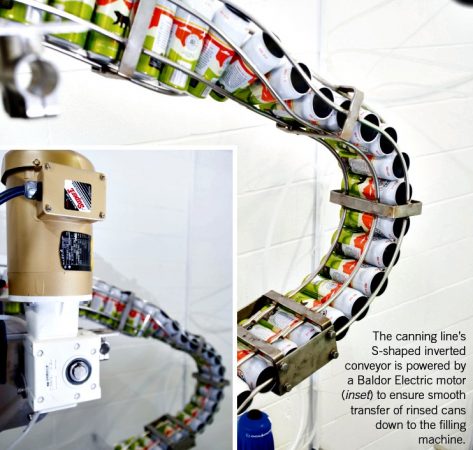

The canning line’s S-shaped inverted conveyor is powered by a Baldor Electric motor (inset) to ensure smooth transfer of rinsed cans down to the filling machine.

EARLY PRAISE

Based on the overwhelmingly positive market response to the new can packaging—now retailing province-wide in 65 per cent of the

600-plus LCBO locations and at 45 mainstream Ontario grocery stores operated by leading food retailers Sobey’s, Loblaw’s and Longo’s, along with family-owned Pino’s and La Mantina’s—choosing Cactus to handle the rebranding project seems a brilliant masterstroke.

In fact, Cactus Design principal Ian Fleming credits his team’s personal familiarity with Cameron’s beer as one of key factors behind the highly imaginative and inspired graphic redesign touching on all the main graphic elements and talking points.

“Being craft beer fanatics who have always admired Cameron’s delicious craft beers, the opportunity to update the brand icon and the packaging was a very exciting and interesting project for our agency,” Fleming recalls.

“Although the Cameron’s brand had been around for nearly 20 years, it had not been updated since its launch in 1997,” says Fleming, saying the outdated original packaging had “extremely weak shelf presence” that was just not connecting with LCBO or The Beer Store customers.

This shelf presence deficit became especially pronounced in recent years as LCBO adjusted its retail strategy to place greater emphasis on individual can sales.

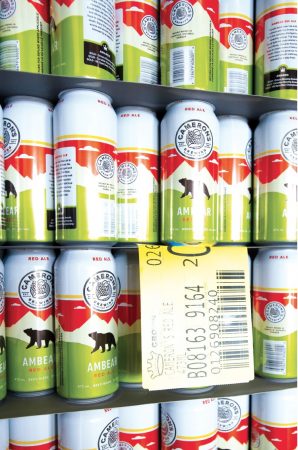

The Cameron’s brewery in Oakville uses the direct-printed aluminum cans shipped in bulk from a Crown Beverage Company plant in Batesville, Miss., to package its three core flagship brands, including its top-selling Ambear Red Ale brand of West Coast-style ale made with caramel malt and Cascade mountain hops to achieve distinctive depth and aroma.

With craft brewers quickly embracing that change with a flood of new canned products, the task of making Cameron’s brands stand out on the crowded shelves was a considerable creative challenge, Fleming acknowledges.

“As the Ontario-made craft beer category has exploded in the past five years, with many new brands coming into the market, packaging has become a very important factor in how consumers feel and engage with craft beer brands,” he explains.

“Most consumers do not have a deep knowledge of craft beer,” Fleming reasons, “so when they go to the Beer Store or LCBO they are

often choosing a section of craft beers to try based on the packaging.

“With the female shoppers increasingly assuming the role of primary purchasers for the family in the important new grocery channels

as well,” he points out, “creating packaging with a distinct and interesting shelf presence that tells a story about the beer and your brand is crucial.”

The new graphics for the Cameron’s three core beer brands represent a striking departure from the quaint but outdated look of the original cans (right) of Cameron’s Lager.

To pull this feat off for Cameron’s, the Cactus team first went about updating the brand’s original ‘Barley Man’ logo, now depicting a stylized bearded farmer carrying oversized barley sheaves tucked under his arm. (See pictures above)

“The challenge was to update the brand icon while still maintaining its history and heritage,” Fleming explains, noting that in addition to being a key packaging graphic, it’s also the main marketing emblem appearing on Cameron’s branded apparel, glassware, coasters and other promotional items.

“The new Barley Man is very distinct, dynamic and modern-looking,” says Fleming, “helping the brand stay fresh and relevant.”

As for the rest of the cans’ packaging real estate, Cactus decided to deploy an array of classic Canadiana imagery—mountains, black bear, lighthouse, sailboats and pine-trees—to lend a unique voice to each of the three core brands.

“The can designs are modern representations of classic Canadian imagery, places and stories,” he explains.

Positioned directly above the canning line on the main floor, the automatic high-level depalletizer supplied by Palmer Canning systems sweeps the layers of empty aluminum cans onto the running conveyors to pass them though the rinser before they are transferred downstairs for filling, seaming and manual case-packing.

NEW DIRECTION

“We were very careful to take a unique direction that would be visually interesting and distinct on the shelf, while maintaining a style that didn’t alienate our long-time customers, but was more likely to attract new ones.

“The cans’ simplistic and colorful graphic style is intended to make them fun and approachable,” he states, “because the Cameron’s brand is inclusive, friendly and approachable.

“You can be a craft beer snob or totally new to craft beer and enjoy our beers just as much.”

Says Fleming: “The Cameron’s team puts so much effort into creating fantastic craft beers, that we had to ensure the packaging communicated innovation and quality, while remaining genuinely authentic to the company and its history.”

According to Coleman and Cameron’s brewmaster Jason Britton, the new cans hit all the high notes spot on with their eye-catching design, which is direct-printed right onto the 473-ml aluminum Tallboy-style cans shipped to the Oakville facility from a Crown Metal Packaging canmaking plant in Batesville, Miss.

“Crown has been supplying us with cans for last the several years,” says Britton, “and we have always been impressed with their high-quality cans that never give us problems on the line.

“We also love their customer service.”

Shipped to Oakville in bulk in towering palletized loads, the colorful cans are filled on the plant’s all-new canning line—installed in early 2016—designed and integrated into a turnkey system by Palmer Canning Systems, Chicago-based beverage line integrator specializing in craft-brewing equipment installations.

A monoblock 12-head counter-pressure filler supplied by the Chicago-based Palmer Canning Systems works in tandem with a single-head seamer (inset top right) to process up to 45 cans of beers per minute, using an Omron touchscreen HMI (human-machine interface) terminal (inset bottom right) to facilitate user-friendly operation for the production staff.

Running at the average throughput speed of 42 cans per minute, the compact system comprises:

- An automatic high-level depalletizer. Stationed directly above the canning line on the main floor, the compact depalletizer sweeps the cans off the pallet layer by layer and rinses the interior of each can via a compact S-shaped rinser;

- A monoblock 12-head counter-pressure filler with a single-head seamer, which purges all the oxygen from the cans prior to filling and quickly applies pull-tab can ends to the top of the precision-filled cans;

- A plastic-belt conveyor, a rinser and a drying station to put finishing touches on each can before they pass through the inkjet date-coder

- A Domino model A320i continuous inkjet coder used to apply highly legible production date codes to the bottom of passing cans.

A Sealed Air Diversey Care sanitation station helps the brewer maintain a rigorous hygienic regime at the facility.

For now, all the case-packing and palletizing is done manually, but Britton says the company is currently studying its options in the marketplace with the view of automating its end-of-line packaging operations, once volume demand justifies the expected ROI

(return-on-investment).

“After the site preparations were done, it took about two weeks to have the system installed and fine-tuned,” says Britton, “and it

was time sell-spent.

“This system has exceeded our expectations as far as commissioning of the line, the installation, and the performance and quality

levels,” he states, adding the company also enjoys “great” local technical support it receives from Buxton Mechanical Solutions, Inc., Palmer Canning’s Canadian representatives.

“After doing our canning on a mobile canning machine prior to this installation,” Britton relates, “we are very happy with how successful we have been with the new Palmer system to date.”

The Cameron’s plant uses high-strength pre-printed corrugated boxes supplied by Shipmaster Containerboard for packing the 24-can cases of beer retailed throughout Ontario at The Beer Store outlets.

The well-maintained Oakville plant currently employs 10 full-time production people to turn out a dozen to about 20 different SKUs (stock-keeping units).

“We are only using a third of the building right now for production, with the other half used primarily for storage of cans, boxes and other supplies, so we have plenty of room to grow and add to our capacity as the market dictates,” he says.

“We have set up the brewery much like a LEGO toy set, all positioned to drop in additional fermenting vessels to boost capacity and new packaging equipment to handle that capacity.

“We strongly believe in automation as a future strategy for us, but the level of that automation has to match our production demands at the time, while maintaining our commitment and passion for handcrafted beer.

“We still have to grow a little more to justify the more intensive automation investment,” says Britton, noting the company’s short-term plans aim to quadruple its current output volumes.

“Right now we are experiencing growth in all of our segments,” says Britton, noting that while canning accounts for about 70 per cent of total production, it draught beer (keg) business is also booming.

Adds Coleman: “The great thing about cans is that you can go into the LCBO and pick out a can from one of several Ontario craft beers and virtually travel the province by sampling them.

“Or taste-test other provinces’ beer, the U.S., or the world for that matter: consumers are migrating to cans because they love their convenience and the uniqueness of the product experience they offer.”

The Brewmaster’s Selection four-packs are packaged in high-strength preprinted paperboard boxes supplied by Shipmaster Containerboard.

While the company’s existing bottling line has been largely underused in recent times, “You never say never in this business,” Britton remarks.

“The market can be cyclical: what’s out of style one day may well be back in style in the future, but at the moment it’s really all about cans for us as a primary focus,” Britton states.

“The growth of our can business has been truly extraordinary, especially since the redesign that has really rejuvenated our brand.”

To keep its market momentum going, Cameron’s is launching a new Brewmaster’s Selection four-pack this month, featuring two cans of the three main brands, along with two new seasonal canned offerings—Black Forest Dark Lager and the Bamberg Castle Smoked Ale.

According to Coleman, the company’s strategy of introducing a new Brewmaster’s Selection four-pack twice a year—packaged in attractive, high-strength folding cartons supplied by the Mississauga-based Zebra Paper Converters—has been exceptionally well-embraced by craft-beer enthusiasts.

“Our four-packs are always popular because we offer consumers a real choice in a small package,” Coleman remarks, “with our two

regular beers and two seasonal beers they may never have had before.”

Both of the seasonal beers in the new Brewmaster’s Selection pack are unique German-inspired recipes made with the freshest and

highest-quality ingredients, Coleman asserts.

“The designs offer a fresh take on a European feel that mixes well with the Canadiana look of the core brands,” he points out.

Because the two seasonal beers are only sold for a limited time from October to February, the Crown-made “silver bullet” cans in which they are packaged are shrinksleeved rather than direct-printed, Coleman explains, due to the short-run print requirements.

“It’s just much more economical,” says Coleman, crediting Toronto-based label manufacturer Tapp Label Company for supplying the colorful, high-quality rollstock shrinksleeves, which are applied onto the cans at a nearby Alliance Packaging plant in Oakville.

“Both Tapp and Alliance are doing a fantastic job for us,” says Coleman, singling out the 12-color Bamberg Castle brand full-body shrinksleeves from Tapp Label for special praise.

For the European-trained brewmaster Britton, the license and freedom to experiment with new flavors and recipes on a regular basis is a priceless perk of the job.

“It’s a very unique and artistic challenge to produce ‘never-before’ beers,with rare and inspiring flavors,” he states. “It really helps us to stay relevant in the marketplace.

“Consumers can always get a beer, but where do they go to find, say, a Scandinavian-style ale brewed with brett and aged in a foeder?

“That’s not as easily available as people may think.

“So as a company, we are always looking for gaps and holes in the marketplace that we can fill with new products, such as our two new German-style seasonals,” says Britton, adding there is really no such thing as too many beers in today’s craft beer market.

“The flavor threshold and the flavor palette are endless, so the more new beer is made by companies that are truly passionate about their beer, the better,” Britton asserts.

“Likewise, the sudden emergence of so many new small brewers is also a good thing for the industry and the consumer public.

“Having a local brewery is like a throwback to having a local butcher, a local baker, a local barber and local candlestick-maker all down the street,” he chuckles. “It is a perfect reflection of today’s ‘buy local’ consumer mindset.”

“The society is changing, and this change is providing us all with an opportunity to show what craft beer is all about.”

Coleman concurs: “In places like Oregon, craft beers account for at least a quarter of all beer sales in the state, whereas in Ontario we’re still at about five or six per cent of the market.

“Even in British Columbia and Alberta, craft beers own 15 per cent of the market,” Coleman points out.

“So when people ask me how long the current growth for Ontario-made craft beers can continue at such a fast pace, I say ‘Forever’.”

The Domino model A201i continuous inkjet printer is used to apply production date codes onto the bottom part of the filled aluminum beer-cans.

As a board member of the Ontario Craft Brewers (OCB) association who is genuinely relishing life in the craft beer business, Coleman devotes a lot of time to helping build up the industry and helping new microbrewers to get up and running.

“This is an industry made up of family-run businesses with an incredible amount of genuine passion for what they do,” he states.

“And personally, I just love the craft beer industry for introducing the general public to all the different and exciting new taste options. “Just 15 years ago, everything tasted almost the same: the pilsners, the lagers, the IPAs … they all tasted alike, with minuscule differences in taste profile and flavor,” Coleman reflects.

“What craft brewers have done is encourage the consumer to be more experimental and adventurous,” he sums up, “and the consumer is in turn pushing the brewers back to be even more experimental and adventurous themselves.

“It is a virtuous circle and long may it continue!”Cameron

Advertisement