Sustainable Superiority

Canadian Packaging

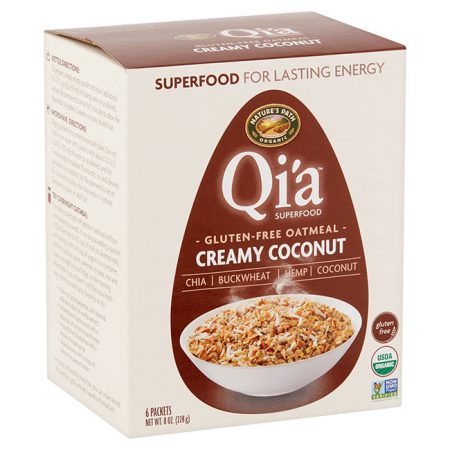

Automation Sustainability Cartoning Case Packing Bosch Packaging Technology Charles Downer & Co. Elematic 3000 WAH XXL Elematic 3001 WA Elematic 3001 WAH Elematic Click System Nature’s Path Foods Qi’a superfoodLeading organic superfooods producer maximizes production efficiencies at a busy cereal processing facility with state-of-the-art packaging automation

The demand for healthy, organic cereal-based products is on the rise, with revenue in Canada for breakfast cereals alone expected to reach 1.2 billion U.S. dollars by 2021.

Consequently, manufacturers need to expand their production capacities and equipment.

The Vancouver-based superfood manufacturer Nature’s Path Foods, Inc. offers consumers high quality, organic and planet-friendly products whilst demonstrating that packaging need not cost the earth.

In order to reduce material waste and boost production efficiency, the company reached out to leading global packaging machinery manufacturer Bosch Packaging Technology, which is represented in Canada by Charles Downer & Co. of Richmond Hill, Ont.

Proudly offering premium, organic and sustainable products to customers all over the world, Nature’s Path Foods, Inc. deeply cares about the health of its customers and the planet, which is why the company is committed to promoting sustainable practices.

Nature’s Path was one of the first companies to sign onto the Food Trade Sustainability Leadership Association’s Declaration of Sustainability.

By upgrading their case packing equipment with a solution from Bosch, Nature’s Path managed to significantly reduce cardboard consumption while also boosting production efficiency.

Nikhil Mehrotra is a Packaging Engineer at Nature’s Path. The Canadian company has been working with Bosch Packaging Technology since 2012. (Source: Nature’s Path)

ON THE RIGHT PATH

Founded back in 1985, the company has adjusted to a number of developments in the retail industry, which includes the recent trend towards wholesale warehouse clubs and supercenters.

These retail outlets offer larger package sizes for customers who want to bulk buy staple ingredients and stock their pantries.

In order to meet this demand for their wholesale products, Nature’s Path decided to offer their products in large stand-up bags and folding cartons of up to 2-kg.

For their corn flakes, granola and crunchy cereals weighing between 325-gram and 750-gram, Nature’s Path began to look for more flexible packaging options.

Whilst market factors and consumer trends certainly influence company processes, they are not the only driver.

“Every decision we make must align with our triple bottom line––being socially responsible, environmentally sustainable, and financially viable,” John Oucharek, director of engineering at Nature’s Path explains.

“In 2010, we became zero-waste certified and pledged to become completely carbon neutral by 2020.”

“This step consequently entailed looking at the environmental impact of our packaging.

Oucharek adds, “As a result, we strive to use our packaging material as efficiently and effectively as possible, and Bosch Packaging Technology has been a reliable partner throughout this journey.”

Nature’s Path has been working with Bosch for a number of years now, starting with a complete packaging line for cereal bars in Blaine, Washington in 2012.

Over the years, the company has expanded their production capacities in order to accommodate their growing 100-percent organic product range, including cereals, oatmeal and granola.

At Nature’s Path facility in Blaine, the Elematic 3000 WAH from Bosch Packaging Technology packs boxes of cereal bars into hooded wrap-around cases.

FORMAT FLEXIBILITY

Nature’s Path started looking for highly flexible case packing solutions for their production sites in Sussex, Wisconsin and Blaine, Washington that would address a very specific challenge: Packaging such delicate products into large, household-size packs.

This can be tricky in terms of filling level, bag roundness and form stability.

The Bosch experts examined these particular needs in great detail and proposed the Elematic 3001 WA wraparound case packer for medium and large sizes for the production site in Blaine.

The machine cartons 325- and 750-gram boxes of Crunch, Hemp Plus Granola and Corn Flakes.

The site in Blaine also needed a new cartoning solution for boxes of cereal bars, so Nature’s Path purchased the Elematic 3001 WAH for hooded wraparound cases.

Bosch also suggested the Elematic 3000 WAH XXL case packer to carton the 225-gram and nd 650-gram stand-up bags of the Qi’a superfood breakfast cereal at Nature’s Path’s production site in Sussex, Wis.

SHELF IMPACT

These case packers are ideal for shelf- and retail-ready products that are transported, stored and displayed in large cases, such as corrugated display bins placed at the end of supermarket aisles.

The machines offer maximum flexibility as they can handle up to 35 different formats, pack styles and product sizes.

Nature’s Path’s processing and packaging lines for cereals comprise a number of machines for filling and cartoning stand-up bags.

As the last machine in the line, Bosch’s Elematic case packers collate the packaged products into corrugated cases.

The Elematic forms and fills up to 25 cases per minute via the lowerator principle, which stands out for its gentle handling and compact case packing.

To make sure the Elematic 3001 WA would integrate into the existing production line, Bosch experts at the packaging design center in Remshalden, Germany worked with Nature’s Path to find a tailored solution for their packaging needs.

“The Bosch team proposed a case packing solution that offers us high production speeds, maximum flexibility and an improved user experience,” Oucharek explains.

“In doing so, they have helped us become more sustainable.

“We managed to reduce our need for corrugated case material by 15 percent, which translated into substantial cost reductions as well as a significant contribution to our environmental mission.”

The Elematic 3001 WA was designed with usability in mind.

SHOOTING BLANKS

Loading blanks into the machine is hassle-free and back friendly due to the low blank magazine.

The case packer’s open and easy-access framework offers another user-friendly advantage: it not only boosts visibility throughout the cartoning process, but also enables operators to quickly clean and adjust the machine.

Thanks to the Elematic Click System, which is a standard feature on the Elematic 3001 series, format changes are tool-free and completely reproducible.

A clearly audible clicking noise indicates to operators when the parts have successfully locked into place.

This eliminates adjustments and minimizes errors, while reducing scheduled downtimes.

Format changeovers can be performed in approximately eight minutes- depending on the grouping pattern.

The machine also features an external hotmelt granulate container and an HMI intuitive control panel which enables operators to program format selection, position, speed, timing and glue position.

ALL ABOUT TRUST

The relationship between Bosch and Nature’s Path is built on trust.

“Having worked together for so long, we have established very close ties, despite the distance and time differences,” Oucharek explains.

“With Jeff Downer, we have a trusted contact person on the ground. Throughout the project, we truly felt that Bosch was there for us.

“For any further questions or issues, we knew we could reach out to Bosch Packaging Technology’s comprehensive customer services via their hub in Raleigh, North Carolina.

Concludes Oucharek: “The team at Bosch took our specific needs into account and really valued our feedback.”

Advertisement