Pure Brew Masterclass – July/August 2016, Canadian Packaging

By George Guidoni, photos by Naomi Hiltz

Bottling Coding & Labeling Corrugated Amsterdam Brewing Company Arpac LLC Arrowhead Systems Ball Corporation Becker Motors CORBY Plastics Festo Inc. Graphic Packaging Corporation Inc. Kisters Kayat Krones Machinery Co. Ltd. Moore Packaging Corporation Owens-Illinois Canada PakTech R.E. Morrison Equipment Corp. Serigraphie Richford SEW-Eurodrive of Canada Ltd. slideshow Videojet Technologies Inc.Stalwart Toronto craft brewer keeps getting better with age through a landmark brewhouse installation and a new state-of-the-art canning line startup.

If there’s one thing that can top doing what one loves for a living, it’s being able to share that love with as many people as one

possibly can.

For Iain McOustra, brewmaster of popular Toronto-based craft brewer Amsterdam Brewing Company, sharing his personal passion for beermaking with beer aficionados across the province of Ontario is a labor of love that just keeps getting sweeter year after year.

Amsterdam Brewing Company owner Jeff Carefoote (left) and brewmaster Iain Mc-Oustra show off some of the company’s premium-quality products and different packaging formats at the retail storefront at the entrance to the company’s 65,000-square-foot brewery located in Toronto’s trendy Leaside neighborhood.

And never more so than following the recent brewhouse installation at the company’s fairly new brewing and production facility operating in mid-town Toronto’s upscale Leaside Village neighborhood, where Amsterdam Brewing moved to in late 2012 after vacating its previous downtown location making way for a new condominium development.

Installed as a fully-integrated, turnkey brewing and canning operation by leading German beverage production line equipment manufacturer Krones AG, the state-of-the-art Steinecker CombiCube B 90-hectoliter compact brewhouse is as much a showcase of made-in-Germany engineering prowess as a testament to Amsterdam Brewing’s ambitions to remain a Top Tier player in Ontario’s burgeoning craft beer business.

Supplied by Krones as a fully-integrated turnkey brewing solution, the compact Steinecker CombiCube B brewhouse at the Leaside plant comprises a mash/wort kettle (foreground), a lautertun to drain the liquid wort, and a whirlpool to remove hop particles.

Founded 30 years ago by local Dutch-born beer enthusiast and entrepreneur Roel Roemer as a neighborhood downtown brewpub in the city’s then-nascent Entertainment District, the privately-owned company has enjoyed remarkable growth over the years to become a popular choice among discerning beer fans throughout Ontario—both at the retail level and at hundreds of pubs and restaurants in the GTA (Greater Toronto Area) region.

The heavy-duty see-though glass plate built into the manway cover on top of the Krones mash/wort kettle facilitates easy visual inspection of the vessel’s interior by personnel.

Leveraging early marketplace success of its flagship Amsterdam Natural Blonde brand pale lager to diversify its product portfolio with a growing range of premium-quality bottled and canned ales, lagers and seasonal varieties, the brewer has consistently combined its knack for product innovation with keen marketing and packaging savvy to cultivate a devoutly loyal customer base well willing to pay a little extra premium for truly outstanding product quality and taste profile.

The Steinecker brewhouse at Amsterdam Brewing is outfitted with a vapor condenser to trap the heat produced by the brewing process, which is then reused to heat up the water used in other parts of the beermaking process.

Nowadays serving well over 1,200 retail and foodservice outlets throughout Ontario, Amsterdam Brewing currently retails about 40 per cent of its output through the provincially-owned LCBO (Liquor Control Board of Ontario) stores and another 40 per cent through The Beer Store locations, with remainder largely accounted by keg sales to pubs, restaurants and taverns, where Amsterdam Natural Blonde remains a highly sought-after on-tap choice for both owner-operators and their customers.

The hop dosing unit integrated into the Steinecker CombiCube B brewhouse ensure extremely precise hop measurement and distribution as a specified by the brew recipe.

Joining the company in 2003, McOustra naturally takes pride in being part of an ambitious and innovative enterprise now producing around 30 different styles of beer each year—adding up to over 28 different SKUs (stock-keeping units)—while

maintaining that the best is yet to come for the fast-growing microbrewer.

Brewing supervisor Morgan Wielgosz taking a peak inside the Steinecker mash/wort kettle through the vessel’s manway cover outfitted with a heavy-duty, airtight-sealed see-through glass panel.

“Our production staff has grown to 93 people from 33 in the three years that we have been at the new facility,” McOustra told Canadian Packaging during a recent visit to the smartly laid-out, 65,000-squarefoot brewery operating a busy 24-hours-a day, five-days-a-week schedule on track to produce 50,000 hectoliters of beer this calendar year.

The combination of a daily three-shift brewing schedule and a full eight-hour packaging shift naturally keeps the Leaside brewery—also housing a busy retail store-front and a special events venue for private parties and banquets—a hive of activity

during the hot summer months.

“We actually have the capacity to produce 80,000 hectoliters annually,” McOustra remarks, “and we definitely plan to reach that level soon.

“But for now, this year’s output will be by far the most beer we will have produced in one year.”

McOustra credits the arrival of the Steinecker brewhouse and other key Krones canning line equipment for much of that volume increase.

One of the brewhouse’s many high-performance SEW-Eurodrive motors providing optimal power distribution to brewhouse operations, using Festo valves and regulators to facilitate energy-efficient equipment operation.

“We are now able to do five different brews per day,” says McOustra, who earned his formal accreditations at the renowned Siebel Institute in Chicago in 2009 and ultimately rose to the position of Amsterdam’s brewmaster in 2013.

During those years, McOustra witnessed first-hand the emergence of canned beer as an unstoppable packaging trend amongst both microbrewers and the mass-production beermakers—driven by consumers’ growing preference for more lightweight, convenient and portable means of enjoying the cold one of their choice either indoors or outside.

This trend is confirmed in Amsterdam’s own sales, McOustra relates, whereby cans now account for 42 per cent of the company’s output, with bottles for 22 per cent and kegs for the remaining 36 per cent.

“The growth in cans has been extraordinary over the last several years,” McOustra reflects.

“With canned beer becoming such an important part of our business, we knew we had to make a serious investment in our canning capabilities to capitalize on this growing segment of the market.

“Cans are doing very well at the LCBO, which is one of our most important sales channels,” he says.

“People are nowadays much more willing to experiment and try different beer styles, and it’s much easier for them to do that by buying individual cans, as opposed to bottled six-packs,” says McOustra.

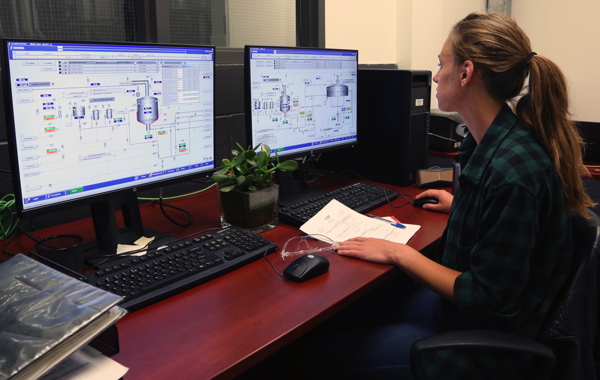

The user-friendly Botec process control system allows brewer Christina Romanin to monitor the entire Steinecker brewhouse operations in real time without any additional assistance.

As McOustra relates, using the brand new Krones equipment has actually enabled Amsterdam Brewing to achieve product quality standards that were previously impossible to attain with the company’s existing, and considerably older, bottling line.

“Our new Craftmate canning line not only enables us to pack 200 cans per minute, compared to 24 per minute that we used to do, but it also keeps the dissolved oxygen content below 40 parts per billion, which is quite outstanding.

“Oxygen is the enemy of beer,” McOustra proclaims, “and keeping the oxygen levels this low allows us to achieve longer shelf-life, while preserving the beers’ freshness and aromas much better than with the previous system.”

Equipped with 24 electropneumatically-controlled filling valves, the Krones Craftmate volumetric can filler is capable of filling between 12,000 and 15,000 cans of beer per hour, depending on can size, using inductive flowmeter technology to ensure consistently precise filling volumes.

Engineered specifically to allow lower-volume craft brewers the flexibility to process a broad range of can sizes and formats, the 24-head volumetric Krones Craftmate filler comes with fully-integrated four-head cappers, a compact valve manifold; an

operator-friendly touchscreen control terminal; an inclined table-top with a fully-enclosed cabinet with integrated pneumatic control systems for the valve manifold; and an integrated CIP (clean-in-place) station connected directly to the brewhouse tanks and vessels.

Freshly-filled beer bottles pass through an air-kinfe station, supplied by R.E. Morrison Equipment, to remove condensation from glass surfaces before case-packing.

A user-friendly control panel of the small-character Videojet inkjet coder used to apply production codes onto the glass bottles enables quick on-the-fly changes.

“This CIP unit is a great value-added feature because it controls all the automatic washing procedures for our canning line,

generating detailed reports for each one,” McOustra relates.

“This in turn enhances our quality control and enables us to reduce the amount of caustic cleaning chemicals used for equipment washdowns.”

For its part, the Steinecker brewhouse equipment comprises:

- a 250-hectoliter hot liquid tank and a 200-hectoliter cold liquid tank for mashing and sparging;

- a new tank-farm consisting of eight 200-hectoliter brewing tanks;

- a hop dosing unit for automatic infusion of hops to the processed brew as specified by the pre-programmed recipe;

- a GEA centrifuge separator for highly efficient removal of solids from the beer, enabling an improved yield;

- a Botec process control system that automatically controls all the key process steps, allowing for just one operator to run the compact brewhouse;

- high-efficiency vapor condenser technology, “Which allows us to capture a good amount of steam energy from the brewing process that we can use to heat up the rest of the water we use in the brewery,” McOustra notes.

The brewery’s canning line operator keeping a keen eye on what’s happening inside the Craftmate volumetric filler by using the system’s iPanel CD touchscreen control panel.

As for the Craftmate can filler, “It’s been running just great since Day One,” he enthuses.

“We were able to set it up in less that two weeks from receiving it in the shipping crate,” McOustra recalls, “and I haven’t had any problems with it since.

“It’s been a real pleasure to work with.”

A close-up view of some of the 24 electropneumatically-controlled precision filler valves housed inside the state-of-the-art Krones Craftmate volumetric filler.

Despite its high throughput speeds, McOustra says the Craftmate filler and the side-by-side Ferrum can seamer are both remarkably gentle with the handling of the 473-ml Tallboy-style aluminum cans used by the brewery to package its stalwart

beer brands, including Amsterdam Natural Blonde, Boneshaker IPA, Cruiser All-Day Pale Ale, Big Wheel Deluxe Amber and the Toronto-centric 416 Lager label, with its playful nod to the city’s original telephone area code.

“We have zero tolerance for product defects here,” McOustra declares. “Being a premium-priced product, our beer has to look as good on the shelf as it tastes inside the package.”

Manufactured and shipped to the Amsterdam Brewing plant in bulk by Ball Corporation, the high-quality 473-ml aluminum beer cans are loaded onto the plant’s overhead accumulation conveyors (above) by a fully-automatic Busse depalletizer (below) before passing through the rinser and traveling on to the Krones Craftmate volumetric filler located on the plant floor below.

Purchased in bulk from a Rexam canmaking facility recently acquired by Ball Corporation as part of a larger corporate asset acquisition, the pallet loads of pre-printed aluminum cans are fed onto the Craftmate line by a powerful, fully-automatic bulk depalletizer manufactured by the Busse/SJI division of prominent packaging machinery group Arrowhead Systems, Inc.

Once unloaded onto a network of interlinked overhead accumulation conveyors, the cans are stood upright and sequentially formed into multiple linear rows that pass through a can rinser before entering the 24-head rotary filler.

After passing through a can warming station to bring the filled beer up to room temperature level, the cans then enter the Ferrum seamer for capping and sealing, before making their way towards the high-performance Kayat case-packing system.

A fully-loaded shipping tray of 24 cans of Amsterdam Natural Blonde lager exits Arpac’s fully-automatic BRANDPAC BPTW-5031 shrinkwrapper securely bundled for transit.

“We use the can warmer to make sure that there is no condensation formed when the beer is placed inside the secondary paper packaging,” McOustra explains.

“Warming it up this way prevents the cans from ‘sweating’ and degrading the multipack cartons’ appearance.”

The Kayat case-packer then swiftly packs the cans in six- and eight-pack folding cartons—boasting clever graphics and other colorful decorative eye-candy—supplied to Amsterdam by the Mississauga, Ont.-based Graphic Packaging Corporation.

For their part, the larger 12- and 24-pack formats are packed into sturdy corrugated trays supplied by Barrie, Ont.-based Moore Packaging Corporation, which are then shrinkwrapped by an Arpac traywrapping machine to hold the cans securely in place until reaching their retail destination.

Instead of using paper bottle labels, Amsterdam Brewing decorates its high-quality glass containers with specialty coating formulations supplied by Sérigraphie Richford.

“We really believe that product innovation is the key force that has kept the company growing over the years,” says McOustra, noting that the company’s satellite Amsterdam Brewhouse on the Lake brewpub, located at the heart of Toronto’s Harbourfront tourist attractions, provides the company with plenty of opportunity to test consumer reaction to its new products right at the source.

Equipped with an on-site 15-hectoliter brewhouse, the 900-seat restaurant “is also our R&D (research-and-development) center where we constantly experiment with new flavors and recipes,” McOustra notes.

“Some of our bestselling beers are fairly new products that have only been developed in the last three or four years,” says McOustra, citing the company’s well-acclaimed Amsterdam Boneshaker IPA as an outstanding recent success story.

With a hefty 7.1-percent alcohol content balanced with citrus and pine flavors and a velvety-mild body, the unfiltered IPA is now the company’s Number One beer band in sales, according to McOustra, despite only being launched less than four years

ago.

“I think we found something unique with this strong beer that really doesn’t taste that strong because of the distinct balance of flavors we have managed to create with this product,” he suggests.

“Although we have now been in points out, “we have always made it a point to keep up with all the new beer styles and to remain innovative, while never shortchanging our customers in terms of quality or consistency.”

Says McOustra: “All of the capital investments and upgrade projects carried out here with the new Krones equipment have really enabled us to make better beer.

“It’s not just about increasing the volume,” he asserts. “New machinery like the brewhouse, the canning line, the centrifuge and so on have allowed us to maintain a more consistent quality of beer, which is the most exciting development for me personally and professionally.

“Despite the growth of the craft beer industry in Ontario in recent years, there are still a lot of consumers out there who have yet to try a craft beer for the first time,” McOustra relates.

“With that in mind, consistency and quality are essential prerequisites.

“We want the consumers who have tried our craft beer for the first time to come back to it, which will not happen if that quality is inconsistent.

“It’s not just important for us here at Amsterdam Brewing,” he emphasizes.

“Without that consistency, people will just simply turn to other options, slowing the growth for the entire craft beer industry.”

With busy summer months seeing the Amsterdam Brewing plant often running flat-out at peak capacity, the Leaside facility makes extensive use of the returnable plastic shipping pallets supplied predominantly by CORBY Plastics.

For Amsterdam’s current owner Jeff Carefoote, who purchased the company 14 years ago, such a scenario would be an epic waste of a once-in-a-lifetime opportunity.

An active participant in many aspects of educational and information programs initiated by the OCB (Ontario Craft Brewers) association, Carefoote says the province’s craft brewers must work hard to take full advantage of the recent loosening of Ontario’s antiquated rules on retail beer sales, whereby selected supermarkets are now able to sell limited quantities of beer alongside their regular beverage products, with Ontario craft beers given prime shelf prominence.

The Amsterdam Brewing Company has always prided itself on the high quality of its glass containers, decorated with proprietary technology from Sérigraphie Richford.

“The legacy of the old rules is that Ontario’s craft beer industry is currently only developed to half the market share levels enjoyed by craft beer in other Canadian provinces, notably in British Columbia, Alberta and Quebec,” Carefoote notes.

Manufactured by Moore Packaging, the pre-printed boxes of Cruiser All Day Pale boxes await their turn to be offloaded from the pallet and placed onto the packaging line.

“A lot of this still has to do with our outdated distribution system,” Carefoote acknowledges, “but ultimately the onus is on craft brewers themselves to supply the marketplace with a product that answers the modern consumers’ expectations for world-class quality, consistency and taste.

“The bottom line is that you have to offer brands that can retain a critical mass among the consumers in order to stick around,” Carefoote sums up, “and I’m not sure that there is room in the market to accommodate all the many new microbrewer startups

just entering the industry in the last couple of years.

“But for those who manage to do things right, as we have striven to do at Amsterdam Brewing for the last 30 years, there will be plenty of good times to enjoy in the years ahead.”

Advertisement