New Beginnings

George Guidoni

Ontario folding-carton company makes a milestone move into a massive new production facility to take its stunning market growth to the proverbial next level

As someone working in the packaging industry for over 40 years, Roy Amm has seen and lived through a plethora of industry’s ups and downs over the decades, along with sweeping technological innovations and ever-changing marketplace dynamics that make packaging such a fiercely competitive and challenging market for many newcomers to crack.

Challenging but not impossible, says Amm, who put his retirement plans on hold about four years ago to join Toronto-headquartered folding-carton manufacturer Beneco Packaging as vice-president of operations and process improvement.

Originally brought on-board to help Beneco achieve the international IFS PacSecure food-contact certifications for its existing operations, the prospect of leading the fast-growing company to reach its enormous market potential and benchmark production excellence proved to be too irresistible to turn down.

“I found retirement to be overrated anyways,” Amm quipped to Canadian Packaging on a recent visit to the company’s vast new 600,000-square-foot facility in Cobourg, Ont.

Currently undergoing extensive renovations and multiple equipment installations to facilitate a smooth operational start-up in early fall, the historic plant has been a venerable landmark for this pleasant southwestern Ontario community—about a one-hour drive east of Toronto—for well over a century.

Having housed illustrious food industry leaders such as General Foods and Kraft over the years—along with a major pharmaceutical company in the earlier part of the 21st Century—the sprawling plant had been sitting dormant for the last three years until Beneco Packaging stepped in to acquire it this past June.

Warmly welcomed by local community and business leaders, Beneco selected the plant as a perfect platform to support and accelerate the company’s future growth—driven by robust market demand for its high-quality paperboard packaging for the food-and- beverage, pharmaceutical, personal care and other fast-moving consumer product industries.

“We had simply reached a saturation point for our production capabilities and capacity at the other plants,” says Amm.

“There was no room to add any more production equipment at our other locations,” he says, “and we really needed new production equipment to be able to keep serving all our existing and new customers.

“Turning down business because we are too busy or too booked up is not an option for a company like Beneco,” he states.

Beneco Packaging president Carol Jiang (left) and vice-president of operations Roy Amm have high expectation for the company’s future growth following the acquisition of a new 600,000-square-foot facility in Cobourg (centre), which is currently in the process of installing a brand new seven-colour Heidelberg printing press (bottom) in time for an early fall start-up.

Founded in 2004 by company president Carol Jiang, Beneco Packaging’s swift rise through the ranks of the Canadian paperboard industry has been a textbook example of bold entrepreneurship and ambition driving continuous proactive capital investment and a sound business strategy built around solid market knowledge and relentless pursuit of manufacturing excellence.

By 2019, Beneco’s manufacturing assets comprised over 250,000 square feet of production space at three facilities, employing a total of over 100 workers and state-of-the-art equipment, including state-of-the-art Heidelberg Speedmaster printing presses renowned for the superior output speeds, operational flexibility and finished print quality.

Moreover, each of the company’s IFS PACsecure audits have the resulted in scores of 95 per cent or better in each of the three years since 2019—opening a multitude to new business opportunities for Beneco with leading retail companies and their suppliers.

For all that, the addition of the new mega-sized facility in Cobourg may well yet be the defining milestone moment in the company’s history, according to Jiang.

“This new plant will definitely become Beneco’s central production hub in the next few years,” says Jiang, who originally started the company at a tiny 6,000-square-foot print shop inside a strip mall in the west Toronto suburb of Etobicoke.

“I think this plant has a great potential for our future growth, with a much larger production area than anything we have had before,” Jiang says.

“Not only will it enable us to install much more production equipment, but it will also allow us to do all our processes in-house in a completely vertically integrated way—from pre-press and make-readies right down to gluing and packing of the final products for delivery to customers.”

According to Jiang, such integration will further improve the company’s already impressive turnaround speeds and lead times for its bigger customers, while also enabling it to look after the multitude of smaller short-run clients who have been there since Beneco’s early days.

(Clockwise from left) A Heidelberg technician having a good look inside the brand new Heidelberg Speedmaster press; close-up of the Heidelberg Speedmaster press control panel; a state-of-the-art sheeter as the first large piece of production machinery to arrive at the Cobourg plant; some of the wooden crating used to ship the brand new Heidelberg Speedmaster printing press to the Cobourg facility earlier this year.

With a giant sheeter, a high-speed die-cutter and a brand new Heidelberg Speedmaster seven-colour litho press already in place at the Cobourg facility, the plant is currently awaiting the impending arrival of another die-cutter and two state-of-the-art folder-gluers to complete its initial capital equipment installations in coming weeks.

According to Amm, the plant will initially hire 20 to 25 full-time people to run the operation, although he expects the plant’s workforce to grow to about 50 people within a year after converting to a two-shift, five-days-a-week operational schedule.

“I think we could well see 100 to 125 people eventually working here in a couple of years once everything is in place.”

Likewise, Amm expects the new plant to achieve the IFS PacSecure accreditation well within the first year or operations.

“That would be our early objective,” Amm states. “All the legwork has already been done at out other facilities in terms of establishing all the proper procedures and processes.

“Now so it’s just a question of transferring all that knowledge and information to the Cobourg plant.

“I cannot say enough about the importance of this certification to our business,” Amm asserts.

“It has introduced us to many larger customers who would not have looked at us before we got certified.”

While the folding carton industry has been through some tough times over last couple of decades, the combination of the COVID-19 pandemic and a broad move by CPG companies to shift away from plastic for environmental reasons has unleashed a massive market surge in demand for paperboard packaging, according to Amm and Jiang, which the industry is having a hard time meeting at the moment.

“The whole move away from plastics has put a lot of pressure on paper packaging suppliers,” Amm explains. “All those McDonald’s Styrofoam boxes and Tim Hortons plastic cups are being rapidly replaced by paper, specifically folding cartons.”

As for the immediate impact of COVID-19, the explosive growth in online shopping and food delivery services during the pandemic-related lockdowns in the food-service industry have also fueled demand for folding cartons and paperboard products to unprecedented levels, Amm points out.

On the downside, the pandemic-induced supply chain disruptions have left many folding-carton producers desperately short of the raw materials (paperboard) they need to make their products.

As Jiang explains, “We do business differently from many other companies, notably in the way we like to carry a lot of raw materials.

“Instead of carrying a lot of inventory of finished product waiting for release,” she says, “we like having a considerable raw material inventory on hand so that we can convert it for us customers very quickly in the time-frame they want.

“We are a very technology-oriented company,” Jiang states, “employing a very strong ERP (enterprise resource planning) system to control and align all our order-processing, along with a state-of-

the-art [ESKO] pre-press system to create make-ready files very quickly.

“Our ability to supply our customers is a key component of our business strategy,” Jiang points out.

“Not being able to supply a customer because we don’t have enough paperboard has always been my biggest fear,” Jiang relates. “It’s nice to be in a sellers’ market for a change as a converter, but it means nothing without having a reliable and steady supply of raw materials to support that work.

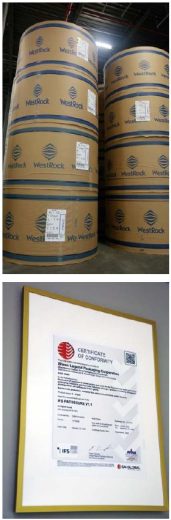

Top: Unopened giant rolls of paperboard supplied by WestRock Corporation resting near the plant’s future production area to be converted into finished folding cartons. Bottom: Close-up of the Certificate of Conformity to the IFS PACsecure standards.

Some of the many entrepreneurial and community awards, including listings on the Canada’s 500 Fastest-Growing Companies rankings of the Profit magazine, won by Beneco Packaging over the years.

“That’s why we have worked hard to enlarge our raw material inventory,” Jiang continues, “while also extending our forecasting from two or three months down the road to five or six months.

“We have essentially gone from the Justin-Time production model to a Just-in-Case type of operation,” Jiang acknowledges, “but that is something we had to do to respond to changing market conditions, with raw materials shortages being experienced throughout North America.

“We have always prided ourselves on our flexibility,” she states, “and you have to be super flexible in this uncertain market.

“We have always been flexible on how we produce, how we perform our changeovers, our delivery dates, and our customer service in general,” Jiang explains, “while maintaining a strict safety and quality through our IFS PACsecure certified process.”

As Jiang explains, Beneco’s customers have been very receptive to the company’s flexible approach of executing smaller but more frequent runs to support their needs on ongoing bases.

As she points out, doing it all in one massive long press run can saddle the customer with unnecessary finished goods inventory or, worse still, run the risk of packaging becoming outdated before it hits the market due to new labeling regulations, ingredient modifications or other unforeseen factors.

“With the current shortages in the market, it is our obligation as an industry to make sure we do not waste any paperboard for any reason,” Jiang says, “including the environmental ones.”

This imperative for waste-free production is especially critical considering a series of strong price increases by North American paper mills in recent months—pushing the average price of board from roughly $1,000 to $1,700 per tonne over the last year.

While such steep rise has forced Beneco to initiate price increases of its own, Jiang says the company is making concerted efforts to keep them in line the best it can.

“There is nothing we can do at this moment about the raw paperboard price increases,” she says, “but none of our customers will hold that against us because we are always in touch communicating with them: we’re like an open book.

“That said, we always try our best to keep our prices fair, especially for our strategic core customers with whom we have built strong business relationships over the years,” she points out.

“It’s more than just about supplying a box for us: it’s about supplying high quality, superior service, and the reliable ability to deliver our product quickly and at a fair price,” she states.

“Being able to do that over the years has enabled Beneco to grow into what it is today,” Jiang concludes, “and we expect the new Cobourg plant to keep us on this course, albeit on a much bigger scale.”

Advertisement