Meat Your Match

Alanna Fairey

Automation Food Safety Sustainability Film Metal Detection Aliments Delstar Foods Cargill Loma IQ2 Loma Systems Lutetia Eduipment R-Series RS420c Salaisons Desco Inc. Schwartz VC999 Canada Ltd. Virginia Deli Weber Weber Slicer 405 Weber Slicer 902 XtraPlast Kostex Xtravac 800 Xtravac 860Meat processing company invests in flexible thermoform packaging technology to leverage packaging sustainability and ensure extended product shelf-life

There are many companies and products that claim to be the best thing since sliced bread, but for Boisbriand, Que.-based Salaisons Desco Inc., being the proverbial best thing in the processed meats industry is the company’s true calling.

Originally founded in 1980 by president Guy Chevalier, Desco began as a 50,000-square-foot facility that exclusively operated as a ham business, before making the shift to smoked Montreal meat back in 2000.

Today, Desco has greatly expanded in square footage and has acquired the globally recognized HACCP (Hazard Analysis and Critical Control Points) and GFSI (Global Food Safety Initiative) certifications and houses approximately 135 employees typically operating two shifts dedicated to production and sanitation.

Desco’s Aliments Delstar Foods and Virginia Deli brand has been sold all across Canada, and can be found in Loblaws and foodservice accounts like Sysco and Gordon Food Service.

From Left: VC999 sales manager Carl-Michel Cloutier, Desco director Joe Ambrosino and VC999 Canada vice-president Daniel Gardner strike a pose.

Joe Ambrosino, director of Desco, credits Desco’s 35-year success not just to their high quality products, but also to their deep commitment to giving customers an authentic deli experience from the comfort of their own home.

“We are very efficient and very knowledgeable about our products and that gives us an advantage,” Ambrosino told Canadian Packaging in a recent interview. “We’re able to turn on a dime, so that gives us an advantage on the open market.

Adds Ambrosino: “It’s always with the idea of trying to recreate the deli experience at home for the consumer ”

In recent years, Desco began to supply their smoked meat and brisket products to the venerable Schwartz brand, inspired by the revered Saint-Laurent, Que.- based restaurant of the same.

Ambrosino shares that although the smoked meat bears the Schwartz brand name, the making of the smoked meat products is much different.

“The brands that we make are Schwartz-at-home, which is different than the restaurant,” Ambrosino relates.

“We’ve come up with a product that is based off of their formula and their recipes.

“But our smoked meat is more conducent to being sold in a grocery chain.”

A Desco machine operator is seen operating the Weber Slicer 902, an easy-to-use, high-performance slicing machine designed to ensure consistent level of precision throughout the process.

For grocery chains to stock their merchandise, Desco needs to ensure that their deli meat products have optimal shelf-life thanks to high quality packaging.

When it came to purchasing, Ambrosino and his team did not have to look much further than the Saint-Germain-de-Grantham, Que.-headquartered VC999 Canada Ltd., a leading supplier of packaging machinery.

Like the old saying goes, Desco and VC999 go way back, having been previously impressed by their experience of providing them with equipment to ensure top shelf-life and high quality packaging on their smoked meat products.

“We bought our first machine from VC999 sometime in the early 2000s and then another machine about eight years ago,” Ambrosino explains.

“The reason why we continue to do business with them is that we found that the product itself is reliable, we have also good service and the quality that you get for the price point is also very good.”

Boasting an impressive output of 10 to 12 cycles per minute, the RS420 thermoforming machine from VC999 Canada has helped Desco to optimize its overall packaging performance, which was a major selling point for Ambrosino and Desco.

Through the guidance and expertise of VC999’s seasoned sales representatives, Desco purchased two full model RS420 thermoforming machines.

In the past, Desco’s other investments in high-performance VC999 equipment comprised of:

- A single RS420c thermoforming machines;

- Two Xtravac 860 automatic chamber machines;

- And a single Xtravac 800 semi-automatic chamber machine.

Desco also purchased XtraPlast Kostex films fromVC999, which are designed to be boilable in an effort to keep moisture in the meat as well as preserve the flavourful taste.

According to Ambrosino, the move to sustainable options has become a necessary means of doing business.

To ensure maximum shelf-life, Desco vacuum-seals their smoked meat product using XtraPlast Kostex films from VC999 Canada Ltd., which can form skin-tight packaging layers around the product in the RS420 thermoforming machine.

“Sustainability in our industry is basically survival, so you have to be able to continue to do things right for your customers,” Ambrosino says.

“Our point is always just to keep the end-user happy and giving them a product that they enjoy and will keep enjoying for a long time.”

Ambrosino says Desco acquired the RS420 thermoformer to achive optimal packaging performance, citing its robust output of 10-12 cycles per minute.

“It runs at a quick pace,” Ambrosino says, “actually faster than we’re able to produce!”

Ideal for portion adequate industrial packaging of fresh food and product innovations, the RS420 seemed like a natural choice for Ambrosino.

From the coveted R-Series, the RS420 thermoformer offers Desco marginal packaging and material storage cost, as the packaging comes in various shapes and can be made off the same rolls of film, which in turn helps Desco to minimize their carbon footprint.

Equipped with a steadfast PLC platform, the RS420 thermoformer has also helped to reduce operating costs for Desco, as the machine necessitates fewer workers to operate.

“I like the RS420 thermoformer’s flexibility,” extols Ambrosino.

“It’s fairly rapid and, overall, the machine is reliable.”

Sourcing their fresh meat from companies in the likes of Cargill, facility workers then begin the process of trimming, marinating and tumbling the meat to lock in the flavour.

Operators then slow roast the meat in smoking ovens, and then typically chill the meat before it is taken to the slicing department.

Leading slicing equipment manufacturer Weber, Inc. supplied Desco with two Weber Slicer 902 slicing machines that slice large cuts of meat into extremely thin slices for the portioned products with remarkable precision and consistency.

“We have had great results with our Weber slicers, which play a very important role on our production lines,” Ambrosino remarks.

“They have been very reliable and god knows we work them pretty hard,” he states, adding that Desco has recently purchased a new Weber Slicer 405 model slicer to further beef up its throughput.

Once sliced, the meat is then promptly moved along to the RS420 thermoformer, where it forms a pocket so that workers can fit Desco’s individual pouches of 125- or 175-gram varieties into the pocket.

Once in the pocket, the RS420 thermoformer then applies the forming web and the XtraPlast Kostex film goes on top of the forming web and it is then vacuum-sealed, so that the product has an extended shelf-life of a minimum of 65 days.

After it is packaged, the meat is pasteurized in pasteurization equipment from Lutetia Eduipment.

Once vacuum-sealed and pasteurized, the finished smoked meat product is run through Loma Systems’ high-sensitivity model IQ2 metal detector to verify that no ptential contaminants inadvertently made their way into the product.

Once the meat has been pasteurized, the meat is promptly run through the Loma IQ2 Metal Detector, supplied by Loma Systems, to ensure that no possible contaminants inadvertently made their way into the package.

Once successfully run through the metal detector, the finished sliced smoked meat product comes out the other end, and is then packaged into individual boxes of either the four or six per box varieties.

Once packaged, the smoked meat is deemed ready to be distributed for retail sale.

Once again, Ambrosino is pleased with the overall experience purchasing from VC999, who made themselves available to them whenever they were having trouble with the RS420.

“Whenever we have needed service, VC999 has always been quick to respond,” Ambrosino shares.

“They are always there to partner up with us and getting the machine going with the least amount of downtime.”

Asked if Desco would consider purchasing from VC999 again, Ambrosino responds with a resounding, “Yes, definitely.”

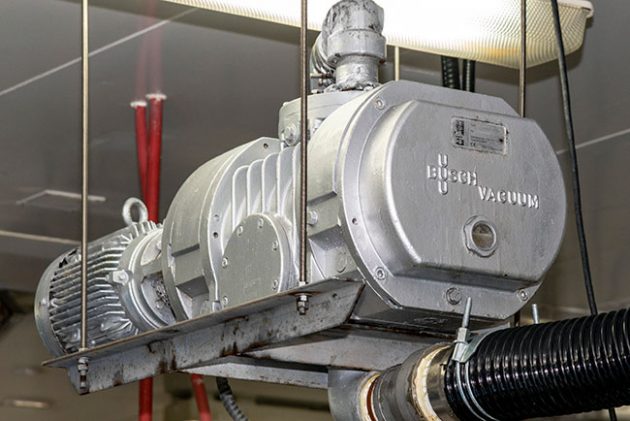

A Busch Panda Booster assists in powering a Busch R5 RA pump inside the VC999 model RS 420 thermoformer system. Desco’s Joe Ambrosino has praised the Busch technology for its exceptional reliability and service support.

As Ambrosino relates, the ultimate goal for Desco is to bring the iconic Canadian Schwartz brand and Montreal smoked meat product to the U.S. market.

While there several other food producers offering similar products, Ambrosino is not unduly worried.

“There’s no more than three or four businesses in the industry that can do exactly the same thing that we do,” Ambrosino proclaims. “We’re probably one of the biggest in the industry as far as the sliced pouches and smoked meat is concerned.”

As he concludes, “Right now, we think that Desco is trying to be on the cutting edge of technology to respond to the consumer demand as we know it.”

– Photos by Pierre Longtin

Advertisement