All The Right Moves – January-February 2017, Canadian Packaging

By Andrew Joseph, Features Editor; Photos by Paul Kritzeck

Automation Case Packing Robotics Delkor Systems Inc. Fanuc America Corporation Nordson Canada Limited Rockwell Automation Inc. slideshowVermont cheese manufacturer keeps the packaging line moving full speed ahead with high-performance automatic secondary packaging equipment

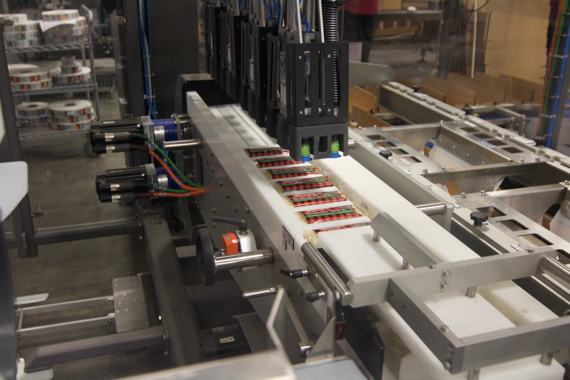

Image above: A top-down view of the index area of the new Delkor Systems C Series 2C 1200 robotic loading case-packing system, featuring the iconic yellow Fanuc M-710iC/50H robot, at the packaging facility of the 1,100-member family farm co-op that own the Cabot Creamery Co-operative plant in Cabot, Vermont.

If you were to travel to Cabot, Vermont, by car, you could almost experience what it’s like to miss a place just because you blinked. Located in an area of 2.8 square kilometers, the tiny community only had a total of 233 people making their home there, according to the 2010 United States Census.

But whatever Cabot lacks in size, it more than makes up for it in cheese.

Operating as part of the Andover, Ma.-headquartered Agri-Mark Dairy Cooperative, the Cabot Creamery Co-Operative Inc. is part of a prospering network of three cheese processing plants operated by Agri-Mark in northeastern U.S.

This includes a cheese processing plant in Chateaugay, N.Y., producing cheddar and muenster cheeses; and West Springfield, Ma., where it makes butter and skim milk powder; a plant in Middlebury, Vt., where cheddar and whey protein powder is made; and Cabot, where it creates its award-winning cheddar cheese and other cultured products.

Best known for its award-winning Cabot brand of cheddar cheese and other dairy products, Cabot Creamery is a classic agricultural dairy co-operative business jointly owned by 1,100 farm families spread across the New York state and New England.

The company was founded in 1919 as the Cabot Creamery Co-operative by 94 local farming families who invested US$3,700 in the original manufacturing plant using a wood-fired boiler.

At that time, dairy farmers produced much more milk than they could sell, so the Cabot farmers churned their excess milk into butter—selling their Rosedale brand all over the New England area.

The main control panel and Rockwell’s Allen-Bradley brand HMI on the Delkor C-Series robotic case-packing system provides Cabot with fast and precise production line efficiency.

As more and more of the population moved away from rural communities to urban confines during the 1920s, the co-operative started to expand its business by shipping some of its milk and butter output south.

By 1930, when Vermont’s human population was actually outnumbered by cows (358,000 people to 421,000 cows), the co-op added cheddar cheese to its production mix.

While Cabot cooperative membership was 600 farms in 1960, the total number of farms across Vermont and the rest of the U.S. begun to shrink. By 1964 there were 9,000 farms in Vermont, and 6,000 in 1967. By the 1980s, there were fewer than 2,000 farms in Vermont, less than one-fifth of the total a mere 10 years earlier.

It wasn’t all doom and gloom for Cabot Creamery Cooperative.

In 1989, the co-op won the first prize at the U.S. Championship Cheese Contest in Green Bay, Wis., starting a remarkable winning streak that continues to this day

To date, the company has garnered nearly 140 major national and international awards, including first place for its cheddar in the 1998 World Championship Cheese Contest.

The turn of the century saw the company undertake a series of strategic moves, including:

• In 2000, Agri-Mark constructed a US$20-million state-of-the-art whey protein processing facility in Middlebury—the only one of its kind in the U.S. at the time;

• In 2003 Agri-Mark merged with Chateaugay Cooperative of Chateaugay, NY;

• Also in 2003, Cabot purchased the MacAdam cheese brand and a plant from Valio of Finland;

• 2006, Agri-Mark joined with the Allied Federation of Cooperatives, adding new members to supply the Chateaugay facility;

• In 2009, larger cheddar vats were installed in Middlebury;

• In 2010, increasing sales prompted the opening of a new 10,400-square-foot warehouse in Middlebury.

“Cabot Creamery Co-operatives still holds onto generations of family traditions, while looking forward in the adoption of best practices to ensure we look after the land, improve animal care, provide a stable business for our member farming families and, of course, make sure we consistently produce high-quality dairy products,” Cabot Creamery cut and wrap production manager Cristin O’Donnell told Canadian Packaging magazine in a recent interview.

She continues: “We look at the cooperative as us supporting our community, and our community supporting us,” O’Donnell states.

The Delkor Systems C Series robotic case-packing system was installed in late 2016 to work with Delkor’s retail-ready Cabrio cases already being used by Cabot Creamery.

There are close to 200 full-time employees at the 119,000-square-foot cut-and-wrap facility in Cabot, with an additional 100 employees who work at the manufacturing plant making cheddar cheese and cultured products.

“As the facility name suggests, we cut and wrap aged, flavored and light cheddar, Pepper Jack, Monterey Jack, Muenster, and Horseradish cheeses—all made with local fresh cow’s milk,” O’Donnell relates.

After a Fanuc M-710iC/50H robot places individual packs of cheese into a corrugated Cabrio case, product moves along a conveyor line to a Delkor Capstone F-series 550 case-closer.

The Vermont facility primarily produces the Co-op’s two flagship brands—Cabot and McAdam—but O’Donnell points out that it also makes dairy products for other company brands as well.

“We produce about 200 SKUs (stock-keeping units) at our cut-and-wrap plant,” notes O’Donnell. “And while our exact numbers are proprietary, the Cabot plant alone handles close to a million pounds of milk a day.

“And while all of that milk is used for a variety of dairy products, I can tell you that our cheddar production tops 70 million pounds per year,” O’Donnell reveals, adding that Cabot dairy products can be found on the east coast of the U.S. from Maine south to Florida.

“While our distribution is mostly concentrated along the eastern seaboard of the U.S., our products can be purchased nationally via major stores,” says O’Donnell, citing the likes of Costco, Walmart and Whole Foods Market.

“Across the U.S. grocery segment, our Cabot brand is Number Three in terms of sales of Cheddar, Monterey Jack and Muenster cheeses, behind Kraft and Tillamook,” she notes. “So we’re doing well.”

At the infeed area, the corrugated Cabrio Cases of individual packed cheese await closing via a Nordson ProBlue 7 hotmelt adhesive system within the Delkor Capstone F-series 550 closer.

She adds that while most of Cabot’s dairy products are sold through the standard grocery channel, the company does have an active foodservice division that works directly with individual restaurants and restaurant chains.

In the larger dairy industry beyond the cheddar category O’Donnell says that Cabot Creamery is ranked the Number 46 in sales.

“Our market share varies from region to region,” points out O’Donnell. “In top markets like Vermont or Boston, we have a 20-percent share of all cheeses sold. In our growing markets, that number can be anywhere from five to 10 per cent.

Knowing the industry is key for any business, O’Donnell notes, monitoring how the rise in popularity of yogurt in recent years has caused a corresponding rise in competitive yogurt brands on the market available to consumers.

Not wanting to compete against the industry heavyweights, Cabot stayed away from the single-serve market and instead only offers its GreekYogurt in the two-pound size.

But when it comes to cheeses, Cabot doesn’t shy away from anyone.

“In the cheese category, Kraft and Sargento are the big players,” O’Donnell acknowledges. “While the competition is strong, we just focus on our own product quality and hope that the end consumer can taste the difference.”

The quality exacted into its cheese and dairy products is extended towards its food safety initiatives, with Cabot Creamery achieving its SQF Level 3 certification, the highest level of food safety standards of certification offered by the Safe Quality Food Institute, denoting a comprehensive implementation of safety and quality management systems.

As O’Donnell relates, the co-op’s mission focuses around producing high-quality products and customer service, while ensuring worker safety and sustainability matters within the cooperative as a whole.

“We have specific teams and programs to continually evolve and improve in both safety and sustainability areas,” she states.

O’Donnell notes the Cabot Creamery Co-Operative is the first dairy co-operative in the world to be BCorp-certified, a third-party private certification issued to for-profit businesses with offices in the U.S., Canada, Europe, South America, Australia and New Zealand, awarded for high social sustainability and environmental performance standards.

The cut-and-wrap facility in Cabot runs two shifts of production and one shift of sanitation operating 24-hours-a-day and five-days-a-week, while the cheese production areas run non-stop seven-days-a-week.

O’Donnell relates that the second half of the year is typically the co-op’s busiest time, saying it manages the increased workflow thanks to a combination of planning and a flexible workforce set-up to adjust to the seasonal variations.

An open case in the infeed area of the Delkor C-series 2C 1200 case-loader neatly stacked and packed with Cabot’s famous Seriously Sharp Cheddar Cheese.

Featuring 11 production lines, the cut-and-wrap facility packs dairy product ranging in size from four ounces up to 38 pounds in various substrates, such as film, bags and wax.

“Different lines are set up with different amounts of automation,” explains O’Donnell. “While we still perform more manual production on lower volume and specialty lines, our highest volume lines have the most automation.”

Cheeses are brought in to the facility from company warehouses after it has been aged anywhere from six months to three years. Arriving in bulk as 40-pound “blocks” or the appropriately named 640-pound “giant blocks,” depending on what was selected by the Cabot cheese graders to be packed as a specific product, these cheese blocks are then cut to size, as chunks or slices.

“The sizing is dependent on the specifics of each customer in the retail or Club Store or foodservice market segments, and what sizes each prefers,” notes O’Donnell, adding that these cheese products are packed using either Hayssen or Multivac plastic films, Sealed Air Cryovac plastic bags, or wax, depending on customer requirements.

“Again, based on the line, we have case-packers and palletizers, but we also have lines where we hand-pack the cheese into cases and palletize those cases by hand,” O’Donnell relates.

“We transport the finished pallets to our distribution center located just down the road in Montpelier.”

For one of those production lines, in November of 2016 Cabot purchased three pieces of equipment from the St. Paul, Minn.-headquartered Delkor Systems Inc. for a new Delkor C Series robotic loading case-packing workcell, featuring:

• Trayfecta S-series TF-S4 1501 XL former;

• C-series robotic loader featuring a Fanuc M-710iC/50H robot;

• Capstone F-series 550 closer.

Already having enjoyed a positive experience owning and operating a case-packing system from Delkor, O’Donnell says it was a no-brainer to purchase the second one when the time was right.

“It wasn’t just the performance of the original casepacker, which was superb,” she notes, “but it was also the high level of friendly, knowledgeable and timely servicer and support that Delkor provided us.

“We thought was a very important factor in expanding our relationship.”

To meet current and future customer needs for Cabot Creamery, Delkor provided the co-operative with a new case-packing system featuring its Trayfecta S-series, robotic C-series loading system, and its Capstone F-series 550 closer, capable of running at a speed of up to 200 units per minute.

Delkor Systems sales manager Scott Shepard says that the Cabot facility has been a Delkor customer for over 20 years, installing their first Spot-Pak line in 1996 to pack tapered cups of cultured dairy products at a rate of 180 containers per minute.

A second, higher-speed Spot-Pak line was installed in 2012 for the same products to keep up with Cabot’s growing production demands.

These Delkor machines were designed specifically to handle product in tapered cups, an area Delkor has specialized in since its beginnings. According to Shepard, Delkor has a large footprint within the cultured dairy industry, with thousands of machines installed throughout North America.

Says Shepard: “The two Spot-Pak systems pack Cabot’s rigid containers into Spot-Pak packages, Delkor’s patented low-cost pad-shrink shippers.

“The systems have allowed Cabot to enjoy savings on their packaging lines for several years,” continues Shepard, “as Spot-Pak packaging typically costs about half that of a typical corrugated shipping case.”

As for the new robotic case-loader, O’Donnell says it wasn’t about saving money on packaging as much as it was about looking to the future.

Needing to replace an existing casepacker manufactured by another equipment builder after it had reached the end of its expected life, O’Donnell says Cabot had also “seen an increase in the number of customers requesting shelf-ready display cases from us.”

Delkor’s solution could not only provide a case-packer that could meet the current needs of Cabot’s shipping boxes, but it could also offer them a leading retail-ready package (RRP) in the Cabrio Case to meet current and future customer needs.

“We can run the Delkor C Series robotic case-packing line at speeds up to 200 units per minute handling six- to 32-ounce blocks of flowwrapped cheese,” relates O’Donnell.

The robotic case-packer’s Trayfecta S-Series former is, according to Shepard, “Capable of forming economical harness wrap shipping cases, as well as our popular Cabrio Case retail-ready package.”

At the collation area of the Delkor C-series 2C 1200 robotic loader, the EOAT (end-of-arm tool) gently picks flowwrapped packs of cheese and places them within the corrugated Cabrio Cases in preparation for transportation to customers.

He says that in late 2016, Delkor’s Cabrio Case was called out by name in Walmart’s Retail Ready Packaging guide as one of the retail giant’s preferred formats.

“This flexibility to switch from an economical shipper case to an award-winning retail-ready package, and vice versa, enables manufacturers to better future-proof their operation,” continues Shepard.

“The machinery solution we supplied Cabot offers similar benefits in terms of flexibility, and simple, tooless changeover that takes just minutes to implement.”

This Delkor system uses a Fanuc-based robotic case-packer, featuring a M-710-iC/50H five-axis robot arm with a payload capacity of 50-kilograms and a reach of 2,000-mm.

“The Fanuc M-710-iC/50H is a medium-payload robot that is designed to perform high-speed product transfers with a wide range of motion,” says Shepard. “In this case, it enables Cabot to pack into more shallow shipping cases, as well as the deeper Cabrio Case RRP without ever dropping the product.”

Adds Shepard: “With the collation-style robotic loader we chose for Cabot’s application, up to 12 blocks of cheese are loaded per transfer to achieve the desired rates.

“Because Cabot runs several different-size blocks and needs to be prepared for future RRP requirements, we designed a highly-flexible end-of-arm tool (EOAT) for the robot.

“This EOAT allows for a wide range of pack patterns and configurations, including the option to load cheese for horizontal or vertical presentation on the shelf.”

As a certified Level 4 Fanuc Integrator—the highest possible level—Shepard says Delkor offers a wealth of experience and support that Cabot will be able to rely on.

“The simplicity of the modular approach to the system, with separate forming, loading and closing operations, allows the system to be configured to fit into a variety of layouts,” says Shepard, “including the relatively tight area Cabot had available in the facility.”

O’Donnell says that when it came time to purchase the new case-packer, it was very important that it be able to run the exact same corrugated blanks it was running on its existing wraparound machines.

A fully packed case of Cabot’s Seriously Sharp Cheddar Cheese exits the outfeed area of the robotic loader before heading towards the Delkor Capstone F-series 550 hot-melt adhesive closing system.

“We consider the case blank we use to be highly efficient,” mentions O’Donnell, “when compared to a traditional RSCs (regular slotted cases).

“As well, the fact that the Delkor system can allow us to change over from one format to the next in time measured in minutes, was a key deciding factor as well.”

Despite the majority of its business revolving around cheese, there’s nothing cheesy about the Cabot cut-and-wrap facility in Vermont.

“Despite the grassroots basics of the dairy industry, Cabot is run as a modern business, but it also mirrors the values of the farmers who own the business,” says O’Donnell.

“We are a company that cares greatly for people, natural resources, and returning profit to our member farms,” she states.

“And nowadays, we see consumers shifting their purchasing habits from simple ‘item quality’ to ‘company quality,’ which means they want to know if they can stand behind the company and the company’s practices,” O’Donnell concludes.

“When it comes to Cabot Creamery, we find that more and more consumers are choosing our products, and we are striving to ensure that continues well into the future.”

Advertisement