Harpak-ULMA introduces a revolutionary application for their ULMA FLOW-VAC equipment

Canadian Packaging

Automation Design & Innovation Food Safety Controls/Drives FV35 SD sanitary design Harpak-ULMA IFFA ULMA FLOW-VACSolution automates the feeding of a belt vacuum chamber on both sealing bars.

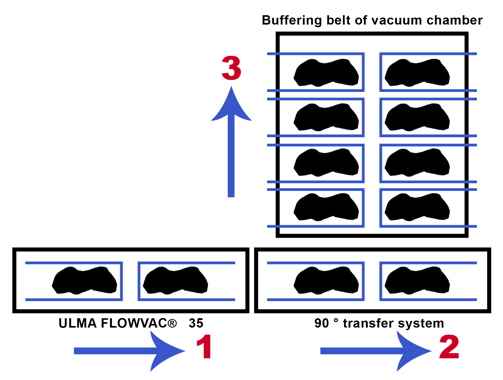

Using patent-pending technology, ULMA has developed a simple but brilliant solution to automate the feeding of a belt vacuum chamber on both sealing bars.

Packages are sealed only on one end and prepared to be transferred to the buffering belt of the vacuum chamber with the open end facing both seal bars on the vacuum chamber.

A 90° transfer system pairs the packages to the buffering belt of the vacuum chamber so that both seal bars can be utilized. If the products are not small enough to be paired, an auto-detect system will load the product as a single item. This automated system increases productivity and reduces labor costs.

The packaging system is ideal for the meat and cheese industry.

See a demo of this smart application on the company’s FV35 SD (Sanitary Design) equipment at IFFA Hall 11 Level 0 Booth B70.

The IFFA tradeshow is being held in Frankfurt, Germany May 7-12, 2016.

Advertisement