Stand-up pouches stand out on shelves

By Carol Zweep, manager of packaging and food labeling services for NSF-GFTC

Design & Innovation Bagging/Weighing Flexibles Paperboard Packaging La Maison Le Grand Nature’s Coffee Kettle NSF-GFTC The Freedonia GroupA White Paper from NSF-GFTC on how stand-up pouches are coming to the forefront of consumer purchases at the retail level.

Increasing numbers of existing and new products are being converted or introduced into the stand-up pouch format. Pouches are a lightweight and unbreakable alternative to glass. Unlike metal cans, pouches can be resealed. Food processors also see benefits of cost savings and sustainability due to lighter weight, lower material use and compact shipping format compared to rigid containers.

Pouches are made of a multilayer structure that combines the best properties of each individual component. Pouch structure can be customized for a variety of applications to meet performance parameters such as stiffness, barrier and high temperature processing requirements. According to The Freedonia Group, the food and beverage markets accounted for 80 percent of the total pouch demand in 2013. Stand-up pouches provide solid opportunities with demand forecast to grow 6.5 percent annually.

Changing Technology

As stand-up pouches become more popular, advances are being made in their application and structure.

- High performance material – Earlier barrier multilayer materials contained foil and metalized films. The new generation of clear film with barrier properties uses silicon oxide and aluminum oxide film coatings to show the appetizing product, allow for microwave compatibility and avoid flex-cracking problems associated with foil. Development of new polymer materials and coatings will enable mulitilayer materials to be made with greater functionality in strength, heat resistance, heat sealability and barrier properties.

- Penetration into new categories – Pouch structure can be customized for a variety of applications. Snacks, confectionery, cookies and cereals have been converted from liner bags in paperboard boxes to stand-up pouches with reclosable features. Flour and sugar have moved from multi-wall paper bags to resealable pouches. Condiments, sauces and dressings have switched from bottles to a pouch format. Prepared icing that was once sold in squeeze tubes can be found in pouches. Microwaveable pouches of frozen vegetables contain self venting technology. Flexible packaging has moved into different food categories where products were traditionally sold in cans and glass bottles. Wine is being sold in pouches with a dispensing spout. Baby food, moist pet food, soups, chili and sauces are being sold in retortable pouches that have undergone thermal processing. UHT (ultra high temperature) milk, which has been dominated by traditional aseptic carton packaging, is now being sold in aseptic pouches.

- Different shapes – Pouches can be made into shapes that convey their message and connect with the consumer, e.g. animal shapes, hourglass or dog bone. Stand-up pouches for milk can be made to appear like the traditional rigid jug with a handle and a pouring spout.

- Easy open and reclose features – A wide range of opening treatments, fitments and closures is available today, including linear tear characteristics, zippers, slider technology and Velcro reclosable options. A screw-on cap can be applied on a spouted pouch for beverages or semi-solid foods. Zip-Pak has created a unique delivery system with a self-contained fitment. The user squeezes the flexible pouch to open the seal and allow liquid product to flow into the dispensing chamber. The package automatically reseals itself for future use (www.zippak.com).

- Textures and graphics – Pouch materials are available in different textures such as gloss and matte, velvet and silky. Matte finish can provide a paper bag or vintage feel that is more aligned with naturalness. Inks and lacquers can provide tactile effects. Colors and graphics can be printed onto the pouches to provide eye-catching shelf presence. Heat- and light-activated inks can cause colors to shift and graphics to appear and disappear. Holographic films reveal images by changes in light.

Innovation

In addition to their many useful attributes, pouches are being designed with creativity and innovation for greater consumer appeal. For example, a cook-in 300 mL stand-up pouch for LeGrand brand Rosée sauces from La Maison Le Grand (www.maisonlegrand.com) takes the shape of an old-fashioned canning jar, complete with a hand-lettered tag attached with a cord. Yes… this is a pouch!

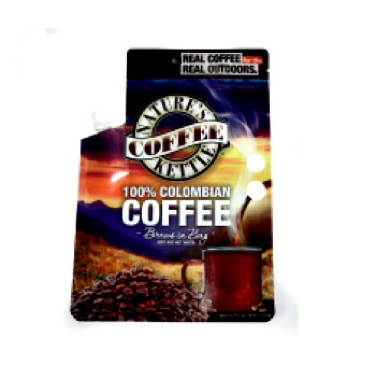

Nature’s Coffee Kettle is a brew-in-the-bag solution for outdoor enthusiasts (www.naturescoffeekettle.com). Four 8-oz. cups of coffee can be made by pouring hot water through the bag’s reclosable, zipper top containing a filter pack of ground coffee. The pouch contains a plastic spout with a cap and insulated finger holes for grasping and pouring.

Consumers are benefiting from the use of portable, lightweight, reclosable stand-up pouches. High impact graphics, custom shapes and textures offer brand differentiation that allows stand-up pouches to stand out on store shelves.

Carol Zweep is the manager, packaging & food labeling, consulting & technical services with the NSF-GFTC.

Carol has experience in quality assurance, testing laboratories and R&D in the packaging field. She is knowledgeable in plastic packaging testing, shelf-life evaluation and has provided training in those areas. Her unique background allows her to help both packaging companies and food and beverage processors by recommending suitable packaging, trouble-shooting packaging issues, performing shelf-life studies and consulting in sustainable packaging options. She is a board member for IOPP Ontario (Institute of Packaging Professionals), and a corporate member of PAC (The Packaging Association). Contact her via e-mail at czweep@nsf.org.

Images courtesy of NSF-GFTC.

Advertisement