Sea change in the air – July/August 2015, Canadian Packaging

By George Guidoni, Editor; Photos by Beatrice Schuler and Naomi Hiltz

Automation Food Safety Sustainability Bagging/Weighing Cartoning Case Packing Coding & Labeling Metal Detection Paperboard Packaging Anthem Worldwide Barry-Wehmiller Hayssen Best Packaging Systems Combi Packaging Systems Domino Printing Sciences plc Graphic Packaging International Heat and Control Canada Inc. High Liner Foods Kliklok-Woodman Labelprint America Loma Systems Nordson Canada Pro-Pals slideshow Weber Marking SystemsFrozen seafood processor champions proactive marine sustainability and relentless product innovation to build up on its hard-earned industry leadership status.

High Liner Foods chief operating officer Jeff O’Neill accompanied by vice-president of retail marketing Kate Galbraith, who heads the leading seafood processor’s ‘Fish for All’ marketing campaign designed to encourage higher levels of fish consumption in Canadian households through education and a more diverse product variety for all age groups.

High Liner Foods is on a mission to help Canadians eat more seafood. At the helm of this mission is Jeff O’Neill, newly-appointed COO (chief operating officer), who is a firm believer that seafood is a key component to a healthy, vibrant lifestyle.

“There’s a plethora of credible studies out there showing the clear nutritional benefits of higher fish and seafood consumption in our diets,” says O’Neill, a high-energy native of Walkerton, Ont., with over 20 years of food industry experience at some of Canada’s largest food multinationals, including Quaker Oats, PepsiCo and McCain Foods.

“Some of these studies show that an average Canadian consumer who introduces fish into their diets as the main dish for two meals a week on a regular basis are likely to see a marked improvement in their cardiovascular heath within four months, along with better brain health and performance,” extols the 45-year-old graduate of St. Mary’s University in Halifax and a holder of an MBA degree from the renowned University of Liverpool in England.

“As Canada’s leading frozen seafood products company, it is our obligation and responsibility to make it easier and more affordable for Canadian consumers to access the health benefits that seafood products can offer,” says O’Neill, who was appointed as the company’s most senior Canadian executive last May following departure of its long-time chief executive officer Henry Demone, now the company’s chairman of the board.

Naturally, achieving a significant and sustained increase in seafood consumption across North America is a direct daily imperative for the $1.2-billion frozen seafood products powerhouse who has propelled its annual revenues fivefold in the last decade with well-executed strategic acquisitions and integration of several prominent East Coast seaboard-based seafood producers such as Fishery Products International (FPI), Viking Seafoods, American Pride Seafoods, and the Icelandic Group’s U.S. and Asian business assets.

Developed by Mississauga, Ont.-based branding and design agency Anthem, High Liner’s new Simply Fish packaging uses clear panels to showcase the product’s freshness, communicate transparency, and improve the tactile shopping experience at the all-important shelf level.

WAY TO GROW

Nowadays sourcing over 30 different edible marine species from 20 countries worldwide to produce a highly diverse portfolio of frozen value-added seafood products for leading North American grocery retailers and foodservice operators at the company’s landmark processing facility in Lunenburg, N.S., High Liner is now focusing its strategic efforts at accelerating the company’s organic marketplace growth in Canada, where it generated sales of $336.7 million in the last year.

Featuring the company’s iconic Captain High Liner brand logo and graphics, the vast majority of value-added boxed frozen fish products, including the bestselling Pan-Sear and Signature brands above, nowadays bear a legible, internationally-recognized MSC (Marine Stewardship Council) ‘eco-label’ validating the product is sourced from sustainable stocks.

As O’Neill relates, the company intends to achieve this primarily through continued product innovation and high-profile marketing efforts based in large part around its highly distinct and attractive retail packaging.

“There are lots of challenges to overcome,” says O’Neill, who joined High Liner in 2011 as vice-president of sales In Canada and proceeded to assume larger responsibilities for marketing right up to his recent appointment as the new COO and president of Canadian operations.

“The macroeconomics are certainly not working in our favor with today’s low Canadian dollar because we purchase all our raw materials in U.S. currency,” says O’Neill.

“Our global procurement model does not really allow us to offset these costs with lower prices for Canadian-sourced fish,” says O’Neill, noting the company had sold off its fishing vessel fleet in the early 1990s following the infamous collapse of East Coast cod stocks from long-term overfishing in the region.

“We currently purchase about 250 million metric tonnes of H&G (headless and gutted) fish from around the world today, which makes it a pretty large shopping basket,” O’Neill told Canadian Packaging in a recent interview at the company’s nominal Canadian headquarters just north of Toronto in Concord, Ont.

“From the species perspective, we mainly stay within the established shipping lanes, with salmon,

cod, haddock, pollock and sole being our mainstay wild-caught species.

“This catch is complemented by farmed salmon, tilapia, bass and shrimp,” says O’Neill, noting that about 70 per cent of High Liner’s raw catch is wild-caught.

While High Liner has been primarily a retail business throughout the company’s illustrious 115-year history, its 2007 acquisition of the aforementioned FPI gave it a major presence in the North American foodservice industry and commodity business, O’Neill relates.

Big bags of frozen seafood pass through the large-aperture model IQ3 inline metal detector from Loma Systems just before being placed into the corrugated shipping boxes.

“Our Canadian business is roughly split 50-50 between retail and foodservice customers,” O’Neill notes, “whereas in the U.S. foodservice accounts for 70 per cent of our sales.

“Today we are the largest value-added seafood supplier in North America,” says O’Neill, citing food distribution giants such as Sysco, Gorton’s and U.S. Foodservice among its biggest distributor clients, along with a long list of quickservice restaurant operators such as the McDonald’s chain, among many others.

“In Canada, we roughly have a 60-percent share in the foodservice market, and a 53-percent share in the value-added frozen fish market,” O’Neill points out.

“In fact, our next-biggest competitor in the Canadian retail space is in fact the private-label store brands, rather than another seafood manufacturer.”

This marketplace dominance and leadership did not just come along by happy accident or overnight, O’Neill quickly asserts.

“Our historical heritage, being a 115-year-old company, is a competitive advantage in its own right, leveraging our industry knowledge and experience,” he points out.

“From a consumer perspective, we have an iconic brand that Canadians instantly connect with,” says O’Neill, citing the company’s venerable trademarked Captain High Liner graphic logo and brand icon that has remained largely unchanged since its introduction in the 1960s.

“We remain a highly resilient company today in large part to our great heritage and great brand equity,” O’Neill reiterates, “which gives us a great foundation to build on into the future.

“We have always been in it for the long haul, and with our approach to quality, procurement, sustainability and how we do business in general, that long-term view is largely responsible for allowing us to enjoy our success today.

“It would have been easy to just close up shop when the East Coast cod stocks collapsed back in the 1990s,” O’Neill states, “but that’s just not how this company operates.”

Started up in 1964, the landmark High Liner Foods processing plant in Lunenburg, N.S., is one of the company’s four major manufacturing facilities located along the Atlantic northeastern seaboard, along with U.S.-based production plants in Portsmouth, N.H., New Bedford, Mass., and Newport News, Va., serving the U.S. foodservice and retail markets.

LESSONS LEARNED

While East Cost cod stocks are projected to bounce back to harvestable levels within the next year or so, O’Neill says High Liner is well aware of its responsibility in ensuring that future commercial fishing activity in the region operates at sustainable levels to avoid another resource depletion calamity.

“We recognize the need to work globally with our fishing partners, NGOs (non-governmental organizations) like the SFP (Sustainable Fishing Partners) and the industry to ensure there are sufficient raw materials in the future to keep our business operating.

“That’s why in 2010 we publicly declared our intention to have 100 per cent of our raw material coming from a sustainable source by the end of 2013,” O’Neill relates.

According to O’Neill, the lion’s share of the company’s flagship masterbrand High Liner packaged products—comprising hundreds of different SKUs (stock-keeping units) and numerous package sizes and formats—today boast the universally-recognized MSC (Marine Stewardship Council) on-pack ‘eco-label’ validating the products’ Certified Sustainable Seafood credentials and classification.

“We announced in 2013 that we got up to 99.1 per cent of all our product coming from sustainable sources, with a few species that we continue to work on today,” says O’Neill.

“But moving from 25 per cent to over 99 per cent in just over three to four years is a really big accomplishment, achieved through some visionary leadership by our company management and a lot of partnership-building with the NGOs and other industry stakeholders,” O’Neill remarks.

A production line operator at the Lunenburg manufacturing facility performs visual inline quality assurance inspection to ensure optimal product appearance and uniformity.

Naturally, this commitment to resource sustainability has gone hand-in-hand with numerous proactive initiatives undertaken by High Liner in recent years to reduce the company’s overall carbon footprint—both on the processing and the packaging side of the business.

“We are fully committed to protecting the environment through responsible business practices, and this commitment extends to our packaging initiatives,” says High Liner’s vice-president of quality assurance, sustainability and government affairs Bill DiMento.

“We have worked hard to make our packaging more sustainable through several efforts, including reducing the size of shipping cases, making our packaging materials lighter, and optimizing truckloads to reduce fuel consumption and maximize storage space,” DiMento relates.

“We also converted the master cartons used to ship foodservice products to kraft paper cartons made from 100-percent recycled fibers,” he continues. “In addition, we now recycle about 90 per cent of the cardboard material that we used to send to landfills.”

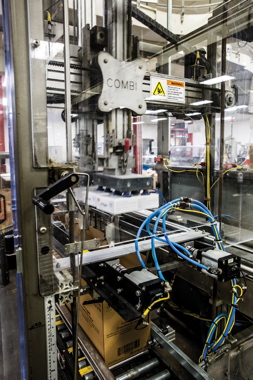

A fully-automatic Combi case-packer is equipped with an integrated Accuglide tapehead from 3M Company to ensure secure and reliable sealing of all loaded shipping cases.

For its part, the company’s historic Lunenburg facility, originally started up in 1964, has implemented numerous environmental upgrades to achieve meaningful reductions in its energy consumption requirements and GHG (greenhouse gas) emissions, according to DiMento.

“We have made a strong effort to reduce our environmental footprint by minimizing the amount of water, energy, carbon footprint, and usage of materials like packaging,” he relates.

“Notably, we have reduced the energy consumption in our Lunenburg facility by 550,000 kWh annually by retrofitting the plant’s lighting,” DiMento reveals.

“On the packaging side, we have redesigned packaging to use less material, while increasing performance, by joining forces with our packaging, ingredient, service and transportation suppliers to find reductions in each of these areas.”

Says DiMento: “We have made it a priority to make sustainable and responsible business practices part of our DNA as an organization to run our business in a responsible and sustainable manner.

“Not only is this good for business,” he explains, “but it also helps secure the long-term health of our oceans and the seafood industry overall.

“That’s why our commitment to environmental sustainability begins at the very top with the senior leadership and extends throughout the organization,” DiMento states.

“We would not be as successful in our environmental sustainability initiatives if our employees didn’t fully embrace it,” says DiMento, noting that some of the company’s more successful environmental initiatives came as a result of partnerships with some of similarly green-minded key clients.

“Many of our key customers, from Walmart to Sysco, have been the driving force behind sustainability improvements and we’ve always held the belief that what’s important to our customers is important to us,” DiMento proclaims.

Kate Galbraith joins the Lunenburg plant’s manufacturing business partner John Mills by the Ishida weighscales dispensing exact portions of fish strips and nuggets.

SHARED VALUES

“We only work with suppliers and partners who share our vision on responsible business practices because they truly understand their role is helping us drive improvements in our business.”

For suppliers who embrace High Liner’s penchant for collaborative partnerships built on mutual trust and respect, the rewards can be immensely gratifying.

Packed in litho-printed paperboard cartons produced by Graphic Packaging in Montreal, the new Captain Crew strips and nuggets clearly aim at the young-age demographics.

Based in Mississauga, Ont., Anthem is a branding and packaging design agency that is by any measure one of High Liner’s most trusted partners.

For the past 20 years, Anthem has been helping High Liner create more powerful brands that stand out on shelf.

According to Anthem, this long-running relationship has been built on mutual trust, collaboration and creative license.

“We are extremely proud of having been High Liner’s sole supplier of packaging design for two decades,” says Anthem account manager Bernadette Sheppard.

“Because High Liner knows we will always respect their brand equities, they give us creative freedom to explore fresh new ideas for redesigns and new product launches.”

The Alpha Compact inline label applicator from Weber Marking Systems attaches pre-printed product labels to the filled boxes of High Liner’s many foodservice product offerings.

According to Sheppard, this long-nurtured relationship was instrumental in the quick and well-executed packaging design of High Liner’s new Simply Fish line.

Representing High Liner’s very first foray into the fresh fish category, Simply Fish was launched across Canada in October of 2014.

The brand provides Canadian consumers with a choice of fresh, premium-quality boneless fillets in wild-caught cod, sole, haddock and salmon.

Bagged and sealed portions of breaded chicken strips emerge from a Barry-Wehmiller Hayssen vertical bagging machine, controlled via an Allen-Bradley PanelView touchscreen terminal, onto an incline bucket elevator for swift transfer to the boxing stage.

The Simply Fish products are beautifully packaged in High Liner-branded trays that earned Anthem a Silver Award at last year’s PAC Global Leadership Awards competition in Toronto.

“Thanks to the high level of cooperation between High Liner and ourselves, everything came together pretty quickly—five to six months between the initial briefing and final execution—to meet the launch dates to which the retailers had committed,” Sheppard recalls.

“We even jointly developed the Simply Fish name by collectively brainstorming the best ways to communicate this new offering to Canadians,” she confides.

“We wanted to convey that this is a whole new way for people to buy fresh fish products outside of the traditional fresh meat counters in store.

“Because it was crucial that consumers understood they were buying fresh, just-caught fish, we felt it would be very compelling for them to see the product for themselves in its fresh state,” Sheppard explains.

“For this reason, we opted for largely transparent packaging to provide a physical touch point at shelf that would complement the shoppers’ emotional engagement. We felt this level of transparency would also drive purchasing frequency.”

Adds Anthem’s strategy director Jennifer Murtell: “With freshness being such an important differentiator, it was really important to go more transparent in order to show off the raw product.

“Unlike the frozen seafood packages that primarily carry pictures of the final cooked product, showing off the freshness and the texture of the fish became much more important than providing a recipe inspiration.”

Supplied by Heat and Control, the fully-automatic Ishida brand multihead weighscales measure out precise portions of breaded fish strips fed inside a Hayssen vertical bagger.

Well before these physical design elements were put into play, Murtell led the strategic restructuring of the High Liner brand portfolio.

“We reconsidered and tweaked the portfolio architecture across the product line-up so that it would be more consumer-relevant and intuitive,” she explains. “This entailed identifying consumer need states, as well as focusing on and organizing the offerings in a way that encouraged easier shopping.”

For this broader High Liner repositioning—as well as the new Simply Fish branding—Anthem conducted a full assessment of how modern consumers shop and choose a brand to create the intuitive means to do so with the right packaging.

“Our primary creative challenge with Simply Fish was to ensure that we leveraged all of the power, heritage and credibility behind the High Liner brand, while still communicating the product’s novelty to consumers. At the end of the day, we wanted this to be a whole new purchasing experience for them.”

A high-speed Vari-Right topload carton former made by Kliklok-Woodman works with a Nordson hot-melt applicator to ensure secure sealing of the tiny boxes of frozen shrimp.

To project the new brand’s premium product designation and optimize shelf appeal, High Liner decided to go with black plastic trays—said to be fully recyclable, featuring high recycled content—seal-wrapped with a layer of clear and sturdy barrier film with minimal graphics and maximum open space on one side for product presentation.

The top film layer is flexographically printed in six colors by the Laval, Que.-based flexible packaging converter Pro-Pals, while the back of the package uses stick-on product labels—containing the Nutrition Facts box, ingredient listings and other key product information—that are litho printed in five colors by Labelprint America of Newburyport, Mass.

While it’s still too early in the game to quantify exactly how well the Simply Fish line has responded with the Canadian consumers, High Liner’s O’Neill is confident that the company is on the right track with both the product and its packaging design, style and format.

Close-up view of the Combi case-packing machine, which is integrated with a fully-automatic stacking station installed by Best Packaging Systems Inc.

A high-speed Domino model C6000 inkjet case-coder applies all the required variable product information onto the sides of filled shipping cases.

A close-up of the product code and production date applied by the Domino A100 A-Series inkjet coding system.

While acknowledging that entering a whole new retail store space is never a risk-free undertaking, O’Neill is counting on High Liner’s powerful brand equity and strong consumer brand loyalty and recognition to help the Simply Fish brand venture succeed, without cutting into sales of its popular mainstay frozen brands such as High Liner Fish Sticks, Signature, Pan-Sear Selects and Flame Savours, among others.

“We are in it for the long haul in the fresh fish category,” O’Neill proclaims. “Our Simply Fish launch was all about helping discount retailers who don’t have in-store counters to satisfy their costumers who want the fresh fish experience.

Placed next to a Fumex fume extractor, a Domino S-Series laser coder generates permanent, highly-legible product codes etched into the paperboard boxes containing High Liner’s frozen products.

“Up to now, it’s been a segment with 99-percent domination by private-label offerings, with no branding presence in the fresh fish format to speak of.

“So we thought it was a natural way to introduce the High Liner brand equity into that next-frontier fresh-fish segment,” O’Neill continues. “It has so far worked better in some places than others, but we are learning a lot from this experience.

“I think that Simply Fish will evolve with our long-term commitment to the idea and the value of providing an exciting new consumption opportunity for consumers in a different area of the store.

“We feel that the convenience of providing value-added, portioned glazed fish that’s ready to cook in minutes to produce a quality, low-calorie serving of good-for-you protein fills an important void in the market,” says O’Neill, complementing Anthem for its original Simply Fish packaging design and structure that maintains the product’s shelf-life for five to seven days at the store-shelf level.

Kate Galbraith enjoying a coastline break within walking distance to the Lunenburg seafood processing facility.

“From a segment perspective it’s breakthrough packaging at its best,” O’Neill concludes. “Compared to the traditional white foam-tray-in-shrinkwrap treatment, this package really bring a whole new level of excitement to a raw naked fish fillet by letting the consumer see the product in an attractive, upscale presentation that reflects this product line’s premium value and appeal.”

Advertisement