Kitchen Rules – January-February 2017, Canadian Packaging

By Andrew Joseph, Features Editor; Photos by Devon Riel

Automation Bagging/Weighing X-Ray Bemis Company Inc. Eagle Product Inspection Plan Automation slideshowAlberta soup producer takes food safety and product quality to the next higher level with high-speed X-Ray product inspection capabilities

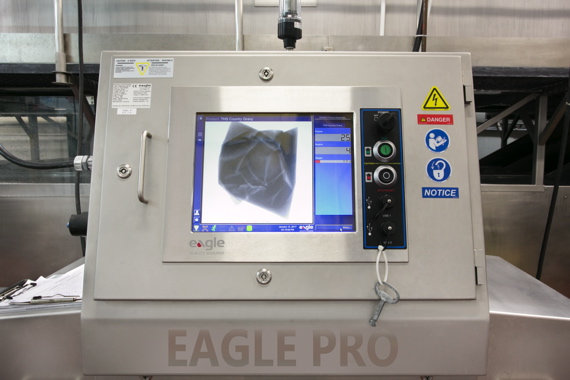

Image above: Kitchen Partners Limited vice-president of operations James Maitland says the company’s new Eagle PACK 320 PRO X-ray inspection system from Eagle Product Inspection, purchased through Canadian packaging systems distributor and integrator PLAN Automation, is helping the food processor maintain high product quality and food safety levels at its Edmonton operation.

It seems fair to say that when it comes to achieving success in the dog-eat-dog business world, there’s no such thing as having too much help from your trusted partners to put you on a firm path to accomplishing your goals and objectives.

Like its name suggests, the privately-owned Kitchen Partners Limited is all about meaningful and successful partnerships. Based in Edmonton, the company specializes in preparing, cooking, chilling, packaging and shipping a wide assortment of liquid foods and sauces to restaurants and retail stores across Canada from Victoria, B.C., to St. John’s, Nfld., with the ability to go south of the border when its customers require it.

“As cliché as some might think it sounds, we believe our customers deserve a partner, not a supplier, and we know that our reputation hinges on the customer’s reputation for providing high-quality, delicious food,” Kitchen Partners vice-president of operations James Maitland told Canadian Packaging in a recent interview.

The company got its start in the mid-1980s in Edmonton when, as a small commissary, it supported some local restaurants by preparing food for them.

A close-up view of a soup pouch passing the reject system of the Eagle Pack 320 PRO X-Ray system, a high-accuracy, high-speed food inspection system featuring robust imaging rates of up 120 meters per minute.

“But, with new ownership in 2004 and a new management team in 2005, Kitchen Partners quickly changed its focus because we knew it could become something more,” says Maitland, with a tip of the hat to company president Jeff Clark.

“We have experienced exceptional growth since then,” he notes, “and we continue to add new customers and new products every year.”

According to Maitland, anything that can be made in a pot on a stove, or served in a bowl at home or in the back of a restaurant kitchen, falls into the Kitchen Partners area of expertise.

“We produce a wide range of products from salad dressings to soups to pasta sauces,” advice Maitland. “We are also licensed for processing seafood as well, and we make some fantastic clam chowders for a few of our customers.”

A Kitchen Partners employees checks the data on the HMI (human-machine interface) on the Eagle PACK 320 Pro X-Ray system to ensure top-flight product inspection at its Edmonton facility to ensure customer and consumer safety for its high-quality soups, sauces, dressings and condiments and more packed in pouches.

With a total of 68 employees, Kitchen Partners operates a 27,000-square-foot facility that houses 5,000 square feet of office space, 13,000 square feet for warehousing and cooling, and 9,000 square feet for manufacturing operations.

“We used to have two facilities, but through efficiency gains and lean manufacturing, we were able to consolidate them into one CFIA (Canadian Food Inspection Agency) federally-inspected, USDA (United States Department of Agriculture)-eligible, GFTC (Guelph Food Technology Centre)-certified building,” Maitland relates.

The company’s main customer segment are the multi-unit foodservice operators and the retail deli/HMR (home meal replacement) service providers, with restaurants making up the largest portion of Kitchen Partners’ business.

While it also produces some industrial support marinades and sauces for other producers, Maitland says that its multi-unit foodservice operators represent over 80 percent of its business, with HMR and institution business accounting for the rest.

With over 100 SKU (stock-keeping units), the company focuses primarily on stirred foods with soups and sauces representing approximately 70 per cent of its output, and the remaining 30 per cent taken up with the production of dips and dressings.

The Eagle PACK 320 Pro X-Ray system Kitchen Partners purchased through Canadian packaging systems integrator PLAN Automation is also used to weigh product pouches for consistency by electronically communicating directly to the food processor’s bag filling machine before inspecting it for food safety assurance.

Customers can either provide Kitchen Partners with their own recipes to follow, says Maitland, or they can have the company create them on their behalf.

“Our business is all about the innovation and the ease-of-use that we can bring to the customer,” relates Maitland.

“That often means that we need to take their ideas and commercialize them.

“Sometimes that means having our team work with their recipes, or us creating them from scratch.

“We have a fantastic product development team at Kitchen Partners that is very creative, with a wide range of capabilities,” he says. “We also hold regular innovation sessions with our customers and their teams, so that we can continue to tailor our business to their business.

“It’s really all about customization here,” says Maitland, describing the two processes employed at the facility: RTE (ready-to-eat) and Cold, whereby it takes meat from a raw state and cooks it so it is RTE.

The robust and accurate Liquiflex filling and bagging system manufactured by Bemis Company saves Kitchen Partners time and costs.

The company runs five-days-a-week, 24-hours-a-day, and tends to have a busier time of year falling between September and December.

“We do have the ability to run overtime shifts, if the project warrants it,” says Maitland, “but for the most part, we have the capacity to scale up our production with the same number of people on the lines.”

Kitchen Partners purchases all of its own ingredients and works with its customers to customize products that meet their needs, according to Maitland. With no brands of its own, Kitchen Partners makes everything proprietary for each specific customer, if required.

“We try to purchase as close to the source as possible,” Maitland reveals. “For example, we buy onions directly from the growers, which are then peeled, cleaned and processed to the exact specification we require.

“We only use fresh ingredients, as we believe that it makes such a major difference in the quality of our products, that you can taste it in the product.

“By buying as close to the source as possible, we eliminate any extra required processing steps, which ultimately leads to a superior product and allows us to customize our products easily to satisfy the end-user’s needs.”

The Kitchen Partners plant operates two basic processing lines: the vegetable preparation manual trimming and prepping line, combined with a highly automatic cleaning step line that feeds the second line—the stirred foods operation.

A bird’s-eye view of pouches of Bolognese sauce moving (from left to right) through the Eagle PACK 320 Pro X-Ray system.

“The vegetable prep line is manual at the beginning, handling all the different types of inputs from celery and cauliflower to onions and bell peppers,” Maitland explains. “Peppers need coring, the onions need to be topped, tailed and peeled, the cauliflower requires destemming, and the celery requires separation—all very different processes.”

Kitchen Partners has opted to automate its critical control points and key process controls, while keeping other processes manual. According to Maitland, this solution provides a high degree of production flexibility for the plant.

“We chose to maintain our manual batching process to provide quality inspection of ingredients and for customization purposes,” relates Maitland. “But for our cooking and chilling operations, we needed to be highly automated to ensure that each step is controlled, and be able to repeat each step precisely to ensure a consistent end product, which can be matched from batch to batch.

“We also prefer to use a manual case-packing method to ensure that every packed product placed into a master case enters in perfect condition,” Maitland confides.

In layman’s terms, Kitchen Partners operation comprises processing of fresh vegetables, scaling of all ingredients, building of emulsions in its batching area, and then adding all the ingredients into its large-scale kettles to cook according to the customer’s recipe.

After the product is prepared, it undergoes a quality check before being released for packaging.

“Once filled, the product passes through an X-Ray system placed a few feet away, with the two machines communicating with each other to ensure the proper fill level is consistent,” says Maitland.

“After the X-Ray inspection, the product is conveyed to pass through our chilling system to cool down to the desired temperature, before being released for boxing and, eventually moved to our finished goods storage area.”

To ensure optimal quality control, Kitchen Partners purchased an Eagle PACK 320 PRO X-Ray system last April 2016.

Manufactured by Eagle Product Inspection of Tampa, Fla., the system is distributed in Canada by the Orangeville, Ont.-headquartered automated packaging systems integrator PLAN Automation, whose X-Ray technical center and warehouse is located in Richmond Hill, Ont.

“We were using a metal detection unit previously,” Maitland recalls, “but we were afforded an opportunity to change to a supplier we could partner with long-term in order to further our own goal of making quality and food safety a competitive advantage.”

Maitland says that because his company uses so many vegetables as part of the product make-up, that stones are inevitably a key area of concern.

Maitland says the same holds true with protein sauce creation, but with the possibility of bone fragments posing the biggest risk.

Maitland says the same holds true with protein sauce creation, but with the possibility of bone fragments posing the biggest risk.

According to Maitland, the combination of checkweighing and improved food safety justified X-Ray as a solution for improving Kitchen Partners’ overall food safety program and reducing the risk to its customers and consumers.

“It has also allowed us to be more consistent on our yields, by having the checkweigher communicate directly to the packing machine and auto adjusting the fill weights,” he notes. “We now have a very small range of variability for each and every package for fill weights.”

The Eagle PACK 320 PRO X-Ray system provides 100-percent product inspection of foreign contaminants, including metal, stone, glass, dense plastics and calcified bone.

As Maitland stresses, the system can checkweigh, measure fill-level and verify component presence or absence, and is capable of multi-lane capable operation.

According to Mat Bedard of PLAN Automation, the Eagle PACK 320 Pro X-Ray system is designed to provide inspection of high-speed flowwrap lines and small- to mid-sized packaged items.

Providing 320-mm (12.5 inch) of detection coverage at the belt, the PACK 320 PRO can perform high-speed imaging at a rate of 120 meters per minute (400 feet per minute) with multiple inspection capabilities.

“All of the Eagle systems are network-capable, which allows users to have remote access to the equipment by Eagle expert technicians, like ourselves, who can provide fast diagnostic relief and hopefully correct any issues without having to send a technician for on-site service,” explains Bedard. “It’s a great way to quickly get production lines working efficiently.”

Adds Maitland: “Kitchen Partners had never had direct experience with X-Ray systems before and had little knowledge of the capabilities that were available to us.

“The PLAN Automation team took the time to educate, share and train our team on all of the options that have allowed us to drastically improve our business and reliability to our customers and their end-users,” he continues.

Having used Eagle equipment at other companies he has worked at in the past, Maitland notes that its capabilities, service and price were second to none.

“I based my final decisions around three factors: the company and their values, service and price, says Maitland, adding that Kitchen Partners genuinely believes in the value of partnerships.

“Both Eagle Product Inspection and PLAN Automation have demonstrated to me over my career in the industry that they have what it takes to create a dynamic partnership, which made the purchasing decision a lot easier for us,” relates Maitland.

With regards to PLAN Automation’s technical expertise, Maitland has nothing but high praise.

“JP Perrault and PLAN Automation have always done great work in many of the plants I had the pleasure of leading,” he says. “Their service and values are superb, which really defines how their technicians conduct themselves in aligning with our personnel here at Kitchen Partners.

“Having PLAN Automation as a partner was an easy decision.”

Maitland says that the Eagle PACK 320 Pro X-Ray system has been doing yeomen’s work for Kitchen Partners, allowing the plant to not only improve the bag weight consistency, but also to work with its own suppliers to improve their food safety programs.

“Since the Eagle PACK 320 Pro X-Ray system was installed over the second weekend of July 2016, we have been able to provide feedback to our suppliers around how their detection systems are working,” Maitland reveals.

“Not allowing any bone fragments or stones to be included into our food products for consumers to find has made our entire supply chain more efficient and safe.”

A Kitchen Partners plant employee oversees the filling and sealing of soup pouches performed by Bemis Company’s Liquiflex bagger, which is capable of processing different-sized pouches ranging from six ounces to five gallons in volume.

Even before the X-Ray system was installed, Maitland recalls how Bedard invited him to visit PLAN Automation’s X-Ray center to see and test a wide range of Kitchen Partners’ products first-hand.

“Matt Bedard did a fantastic job in fitting us with a solution for our process, including adding a rejection system,” says Maitland, adding the company was kept in the loop throughout the entire process, and that when technician Josh Milne arrived to install and teach Kitchen Partners’ staff how to use the equipment, they already felt he was part of the family.

“Josh really fit in with our culture and values,” explains Maitland. “It felt like he had worked with our entire team for years.

“He had the set-up done quickly and effectively, and worked with our entire team to ensure everyone had the proper training we needed to ensure safe and effective operation of the X-Ray system.

“For me, all of the interactions were a true reflection of PLAN Automation’s leadership, and I am proud to have them as partners of Kitchen Partners.”

Maitland says that the foodservice industry is both very exciting and competitive, adding that Kitchen Partners has found its niche and has continued to grow it over the years.

“Whether it’s with new products offered to existing customers or simply attracting new customers, we have discovered, and will continue to discover, new business opportunities for Kitchen Partners,” Maitland opines.

He points out that recent trends of cleaner ingredient declarations, and full customization options are “trends we are seeing and are able to take full advantage of.”

On top of all that, it is the quality of the food they produce, and the safety aspects they can offer their customer’s consumers that set Kitchen Partner’s apart.

Kitchen Partners follows OSHA (Occupational Health and Safety Administration) standards, with Maitland proudly citing his company’s record 1,162 consecutive days of no time lost due to worker accidents, at the time of this writing.

Along with a comprehensive quality and food safety scorecard in which Kitchen Partners measures a wide range of criteria, Maitland points to the plant running on “an OEE (overall equipment effectiveness) metric to calculate efficiency yields and utilization over a five-day, 24-hour schedule, with us running at an average of 79 per cent right now.

“As for fill-rate, if we drop below 99.7 per cent, then there is a serious problem,” Maitland acknowledges.

“So we decided that scheduling conformance was a better metric, where we target 97 per cent of plan.”

Summing up, Maitland says he is optimistic about his company’s continued growth and ability to produce high-quality, safe food for its customers.

“Having a great partner like PLAN Automation has certainly been a great way for Kitchen Partners to improve our efficiency,” Maitland concludes.

“And we are glad to have them with us as we continue to take things to next level in the foodservice industry.”

Advertisement