GOOD THINGS IN small PACKAGES – January/February 2015, Canadian Packaging

By George Guidoni, Editor; Photos by Cole Garside

Automation Design & Innovation Cartoning Case Packing Corrugated Allied Flex Technologies Atlantic Packaging Products Ltd. CHEP Canada Inc. Eagle Packaging Machinery LLC JG Packaging RJP Packaging Robert’s Packaging Equipment SEW-Eurodrive Co. of Canada Ltd. slideshow Speedway Packaging Machinery Inc. UniTrak CorporationPrivate-label detergent manufacturer leverages high product quality and formidable manufacturing prowess to clean up in the fiercely competitive market segment

The Concord plant has the capacity to produce over 1.5 billion of single-use, monodose packets of powder and liquid pods of automatic dishwasher detergent per year.

Too much of a good thing is never really enough in most consumer packaged goods industries.

And it’s hardly a stretch to say that things are looking good indeed these days for JemPak GK Inc.—a fast-growing manufacturer of automatic dishwasher detergents who is really cleaning up, business-wise, in the product category’s buoyant, yet fiercely competitive, private-label segment.

Brought back to life from looming bankruptcy three years ago by a team of local investors and corporate turnaround experts, the recently renamed and refocused producer of household cleaning chemicals—formerly operating under the Witco Chemical banner—is a happy testament to the virtues of sound management skills, manufacturing and packaging excellence, and a proactive R&D (research and development) mindset as key prerequisites for corporate rejuvenation and renewal.

A one-time manufacturer of fabric softener sheets for household laundry chores, the company’s fully-revamped, 80,000-square-foot factory just north of Toronto in Concord, Ont., today ranks as one of North America’s three largest producers of the so-called ‘monodose’ pods of powder blends retailed as dishwasher detergent store brands of some of the world’s most prolific retail chains, including Big Box powerhouses Costco and Walmart.

For JemPak’s vice-president of operations Emil Tarnowsky, the decision by the company’s new owners to exit the fabric sheet business and start producing the popular, consumer-friendly, single-use packets of concentrated dishwasher and laundry powders was a monumental game-changer that breathed a whole new life and purpose into the Concord operation, along with its smaller sister plant in nearby Oakville that produces private-label liquid laundry detergents.

“Manufacturing softener sheets was a dying commodity business back in 2011 when the new owners came in, so refocusing our market focus was critical to keep this plant going,” Tarnowsky told Canadian Packaging on a recent visit to the 70-employee Concord operation.

From Left: JemPak president Steve Miller, chief executive officer Charles Zuckerman, and vice-president of operations Emil Tarnowsky show off some of the high-quality dishwasher and laundry detergents manufactured in various packaging formats for its private-label customers at the company’s Ontario-based production facilities in Concord and Oakville.

Drawing an analogy with hockey icon Wayne Gretzky to make a point, “What made him such a great player was not his ability to follow the puck but being in the right place just where he thought the puck would arrive,” Tarnowsky explains. “And much in the same way, we decided to enter the monodose segment because that’s where we saw the whole detergent market moving.

“And it has paid off big-time for us,” beams Tarnowsky, citing JemPak’s annual sales of over $50 million and a loyal client base comprising some of the leading lights in the global retail business.

“It’s all about consumer convenience with the monodose products,” says Tarnowsky, adding the busy, two-shift Concord plant now boasts capacity to produce about 1.5 billion packs of variable quantities of individual pods annually.

“You just pick it up, pop it into a dishwasher and away you go, all without the hassle of measuring and pouring powders and gels into the dishwasher yourself, making it such a chore,” Tarnowsky says, relating that 95 per cent of the Concord plant’s production is dedicated to dishwasher powder pods, with the rest for monodose laundry pods.

“The monodose clothes detergents have not yet caught on in the same big way in North America,” he acknowledges, “but it’s growing fast enough where I can see it account for up to 20 per cent of our production down the road.”

It took millions of dollars to completely overhaul the Concord facility to accommodate brand new equipment, manufacturing processes and facility infrastructure to make the monodose products, and for plant manager Robert Poletto, a 25-year manufacturing industry veteran with a strong technical background in industrial instrumentation, it was money well-spent by any measure.

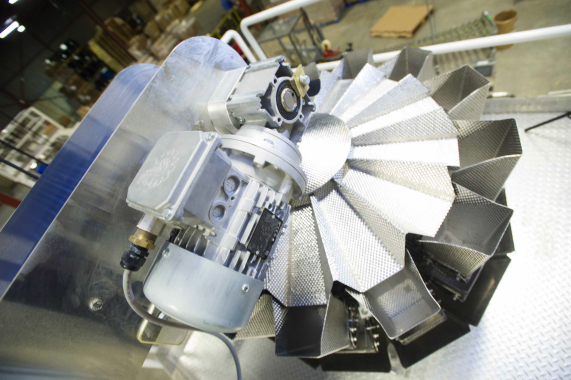

High-precision 14-head Multiweigh scales installed by RJP Packaging are used to dispense precise quantities of dishwashing detergent pods down to the packaging lines.

CAPITAL GAINS

“We have invested a lot of resources in the business and we will continue to do so because that’s what gives us our competitive edge,” says Poletto, who personally oversaw the installation of the plant’s two high-performance packaging lines handling the conversion of bulk ingredients kept in massive super sacks into the finger-sized monodose sachets, blended in a multitude of different formulation recipes, packed inside the retail plastic tubs and stand-up pouches shipped to the retailers’ outlets.

“The actual conversion process into the final product is actually pretty quick, a matter of seconds, which has been made possible by the well-executed integration of highly automated process and packaging equipment at this facility,” says Poletto, while also crediting the plant’s highly dedicated workforce for embracing the new technology and processes.

Precise quantities of filled stand-up pouches of dishwasher detergent pods making their way out of the fully-automatic collator manufactured by Eagle Packaging Machinery.

“While there was some initial concern when the company first decided to refocus the business, the employees really grasped the opportunity to learn something new and to grow themselves in terms of their skillsets,” Poletto relates.

“When we started production in 2012 we had achieved equipment reliability rates of over 90 per cent within three weeks,” Poletto points out.

“This is something I personally like to brag about,” he chuckles, “because it really demonstrates our employees’ level of knowledge and commitment.

“With all this new technology coming into the plant, it is a big credit to them and their collective ability to absorb it all, learn as much as they can, and put it all into place to make the best-quality product possible for our customers,” Poletto reflects.

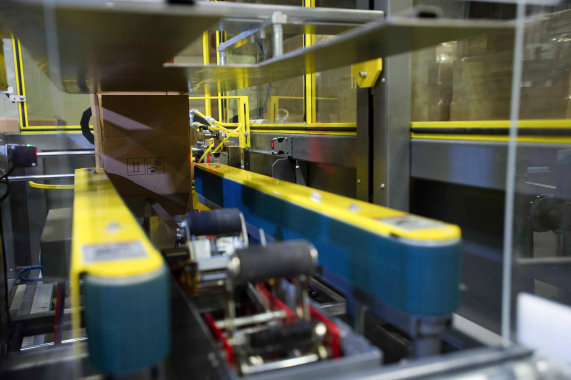

Filled stand-up pouches travel alongside corrugated shipping cases coming out of the Eagle Packaging case-erector to the line operator, to be inserted inside the boxes.

The plant’s unwavering commitment to continuous improvement and product quality, as evidenced by frequent stringent quality checks and analyses of all the many formulations blended and packaged over the course of a daily shift, underpins all the success and growth that the operations has achieved so far in growing its client base, Poletto asserts.

Not only does JemPak supply Costco stores with its private-label detergent pods throughout Canada and the U.S., he points out, it also ships them to the retailer’s overseas locations in the U.K, Spain, Australia and Taiwan.

Massive batches of freshly blended and screened dishwasher powder detergent are placed into heavy-duty woven bulk super-sacks in sequential order prior to packaging.

“We would not be able to do this unless we ran a cost-efficient operation making a sufficiently high-quality product that commands a sufficient price-point to cover our costs and to provide reasonable margins for our business,” Poletto reasons.

“Naturally, this involves a fair amount of automation and operational flexibility, which we have built into the process from the outset as we brought in all the new equipment.”

A heavy-duty SEW-Eurodive motor (foreground) powers the Speedway conveyors transferring stand-up pouches inside the Eagle Packaging collating machine.

An automatic case-sealing machine from Eagle Packaging Machinery applies strips of high-strength sealing tape onto the top of each passing corrugated box.

A heavy-duty woven super sack filled with bulk powder detergent blend is prepped up for discharge and processing into monodose, single-use dishwashing detergent tablets.

According to Poletto, there are many significant differences in the composition and formulations in the pods produced for all the different customers, which keeps the plant’s on-site blending and screening department busy throughout the year.

The same goes for JemPak’s state-of-the-art R&D center located on-site at the Oakville liquid detergent plant, where highly qualified chemists and other high-skilled personnel continuously work to improve the existing formulations for the customers.

Sourcing its raw ingredients from leading chemical producers around the world, the detergent mixes are blended and screened to specs, thoroughly inspected at various stages by metal detectors and checkweighers, stringently tested for density, consistency and other key requirements, and placed inside large bulk super-sacks—four sacks per every 2,450-kilogram batch of product—to await their transfer to one of the two packaging lines.

Each of the WIP (work-in-progress) batches is meticulously tracked and randomly tested throughout the pre-packaging stages to ensure optimal product quality, Poletto relates.

A Multiweigh checkweigher installed by RJP Packaging verifies the weight of plastic tubs used to package larger quantities of detergent pods preferred by Big Box retail customers.

Boxes coming out of Eagle’s Boxxer T-12 automatic case-erector travel alongside neat rows of stand-up pouches exiting the nearby Eagle collator to be packed for shipping.

The pods themselves are packed on one of two state-of-the-art, custom-made powder fillers outfitted with multiple rows of filling cavities, where the powder is dispensed onto a pre-laid layer of water-soluble film, topped off with another film layer, and instantly heat-sealed with water to create the final, see-through, pillow-shaped individual pods.

“We are really focused on continuous improvement to provide our customers with top product quality and cost-savings, always looking for ways to give them a break on prices as much as possible,” Poletto reveals.

“I really believe that our products are at least as good, if not better, than the national brands they compete with, and that’s down to our focus on maintaining continuous improvement throughout our quality control system.”

“We have a lot of built-in flexibility to give our customers whatever they want, including the larger 110-count tubs preferred by Big Box retailers like Costco to the 12- and 20-pod zippered stand-up pouches formed on our pouchmaking machines,” Poletto relates, complimenting the plant’s two high-performance pouchmaking machines manufactured by Roberts Packaging Equipment, a division of Des Plaines, Ill.-based Cloud Packaging Solutions LLC, and supplied by Allied Flex Technologies, Inc. and JG Packaging.

All of the filled stand-up pouches are quickly transferred to a fully-automatic collating machine—manufactured by Eagle Packaging Machinery LLC—which stacks the pouches in neat, upright rows of product in pre-selected quantities, which travel on in these neat bunches to the case-packing area.

A heavy-duty bulk discharger and bucket elevators from UniTrak Corporation are used to transfer bulk powder up to the automatic weighscales on the mezzanine level above.

Stacks of corrugated carton blanks being loaded into the magazine of the high-speed, automatic Boxxer T-12 case-erecting machine manufactured by Eagle Packaging.

CASE SHUT

Upon arrival, a line operator inserts them by hand into empty corrugated shipping cartons arriving alongside just-in-time on an adjacent conveyor from the nearby automatic Boxxer T-12 case-erecting machine, also supplied by Eagle Packaging.

Once filled, each box proceeds to pass through an automatic Eagle Packaging case-sealer, which quickly applies a precise strip of sealing tape lengthwise to the top of each passing carton.

The sealed boxes then make their way towards two downstream line operators who swiftly stack them onto the nearby wooden pallets in neat layers to fill out the orders.

The finished pallets are then whisked by forklift operators to one of the plant’s three automatic stretchwrapping machines, which applies a secure layer of film around the finished stack to ensure optimal load stability during transport and distribution.

A bird’s-eye view of one of the plant’s two highly-automated packaging lines utilizing high-speed collating, box-erecting and case-sealing equipment from Eagle Packaging.

A close-up view of the Eagle Packaging Machinery’s case-erector feeding the JemPak packaging lines with corrugated shipping boxes made by Atlantic Packaging Products.

Supplied as fully-integrated, turnkey line solutions, the Eagle Packaging machines have proved to be “highly reliable pieces of equipment that immediately adjust themselves to the specific product counts and quantities that we are processing at any one time,” notes Tarnowsky.

“We are very happy with the Eagle equipment’s performance and the fact that we have good local technical support to address whatever issues we may have without incurring any significant machine downtime,” he states.

Naturally, the plant’s line operators constantly monitor the continuous, highly-automated process in real time assurance throughout all packaging steps and stages to ensure optimal product quality and a smooth-running operation.

“A typical powder blend may combine up to 15 different ingredients, so we check everything: from product density and flowability to checkweighing the final packages and individual pack-counts,” notes Poletto.

“We did a lot of work in-house to increase the machine speeds to a point where we can a run a full-out 24/7 schedule if our product needs demand it,” says Poletto, adding the plant is always looking at new ways to boost its productivity and efficiency through additional automation.

“We have recently commissioned a new highly automated blender that will also automate at least a half of the filling steps we must currently perform manually,” he says.

“We are very competitive at what we do: there’s a lot of competition out there right now, and the best way for us to deal with it is to focus on our business of supplying the market with the best-quality product.”

A transfer tube connected to Multiweigh scales overhead dispenses precise quantities of dishwash detergent pods into plastic tubs transferred by the Speedway conveyors below.

The stackable plastic tubs used to package larger quantities of dishwasher detergent pods for Big Box retail customers help to ensure optimal cube utilization during transit.

JemPak’s chief executive officer Charles Zuckerman whole-heartedly concurs, adding that the company’s competitive edge is rooted in its earnest commitment to continuous R&D investment.

“We reinvest about 10 to 15 per cent of what we earn back in R&D, which is pretty high for a company that does not manufacturer brand-name products and, relatively speaking, for a company of limited size and scope.

“But the main reason we have the likes of Costco, Walmart and Dollar General doing business with us is that we have a very strong R&D department that enables us to produce high-quality, cost-effective formulations that are at least as good or better than the national brands.

“That’s the nuts and bolts of what JemPak is all about,” Zuckerman proclaims, adding he is highly upbeat on the company’s growth prospects.

“The monodose dishwasher detergent sector is huge: it astounds me how many of these products are sold every year,” Zuckerman enthuses.

Toronto-based corrugated producer Atlantic Packaging Products Limited supplies the JemPak facility in Concord with high-quality corrugated shipping boxes for transporting stand-up pouches to its North American retail customers.

A high-speed model SPM-10 side wipe-on label applicating system manufactured by Speedway Packaging Machinery swiftly applies pressure-sensitive product labels onto the side panels of plastic tubs with exacting placement precision.

Each filled plastic tub traveling on top of the Speedway plastic conveyors is checked for weight and quantity by the Multiweigh checkweighers prior to lidding and labeling.

“Our plant alone can make 1.5 billion packs of these pods on two production lines,” he notes, “and our much bigger brand-name competitors turn out at least 10 times as many.”

Despite having all the resources and technical know-how to manufacture its own branded products, Zuckerman flatly rejects the notion of doing that any time soon, citing the considerable time, effort and resources invested in building strong relationship with the company’s key private-label customers.

“One of our cardinal rules is that we don’t compete with our customers, so that there is never any whiff of conflict of interest,” he asserts.

“Our job is to make the customers better by making a better product for them—a product that is as good or better than the national brands, but costs less at the retail level.

“The only way we can compete with multibillion-dollar brand companies is to be one step ahead of them in quality, efficiency, and performance of the product,” he says, “which is why we pride ourselves on our R&D activities.

“Our R&D is really the heart of the company, which guides everything from the way we buy machinery to how we implement new processes and to how we approach new customers.

“We don’t just do business with anybody and everybody,” Zuckerman points out.

A tight layer of high-strength stretchwrap film helps to keep palleted loads of stacked plastic tubs secure and stable during product transport and delivery to retail customers.

Fully-palletized finished loads are placed onto the signature-blue CHEP pallets and secured into place with protective film on one of the plant’s three stretchwrappers.

“We are always careful to do business with those companies that have the means and the desire to make their private-label programs successful, as opposed to companies that simply use private-label products to beat up on the brands simply based on price—there’s no longevity for us in that.”

As one of key figures behind the decision to reset the plant’s product focus three years ago, Zuckerman is highly encouraged by JemPak’s dramatic turnaround in fortunes so far, as well as its future prospects.

“If you don’t embrace change to improve your business, you essentially resign yourself to be mired in mediocrity,” he states.

“That’s not for us: we’re all about being the best in everything that we do,” Zuckerman proclaims. “That’s why we chose to compete in the high end of the market, to go up against the best.

“When we realized that we were not going to be able to provide the market with the best fabric softener sheets out there, it was imperative to identify for ourselves a product segment where we would be producing a premium-quality product.

“We deliberately chose to compete in the ‘Top Tier’ because that’s where we can offer the most value to our customers,” Zuckerman concludes, “which in turn brings out the best in us and our employees.”

Please see a video of the Eagle Packaging Equipment collator, case-erector and case-sealer in action at the JemPak plant on Canadian Packaging TV posted on:

https://www.canadianpackaging.com/videos/eagle-landed-jempak/

Advertisement