End Of The Line—October 2017, Canadian Packaging

By Andrew Joseph, Features Editor; Photos by Pierre Longtin

Automation General Cartoning Case Packing Palletizing Robotics Consolidated Technologies FANUC Robotics Canada Festo Canada Industry 4.0 Markem-Imaje Robot Industries slideshowKeeping things in-house allows end-of-line packaging equipment designer and manufacturer to maintain in full control of its automated marvels

Caption: Consolidated Technologies sales manager Christian Lapointe in front of a FANUC robotic end-of-line palletizing solution.

As William Shakespeare’s Juliet once pondered, “What’s in a name?”

Sometimes the answer is as simple and sweet as it is obvious.

For the Vaudreuil-Dorion, Que.-headquartered Consolidated Technologies Inc., what’s in its name is simple—a consolidation of all the different types of end-of-line packaging machines a company needs.

Opening its doors in 1998, Consolidated Technologies might call Canada home, but its machines adorn manufacturing facilities across North America.

A North American leader in the design and production of well-thought out end-of-line machines, the company offers customers a full range of equipment from cartoners, case-packers, sleevers and palletizers selling individually technologies, or consolidating them into a multi-faceted, turnkey packaging solution.

During a recent visit to the tidy, 30,000-square-foot facility with approximately 35 employees, Canadian Packaging talked with Consolidated Technologies sales manager Christian Lapointe, who told the magazine that the key to his company’s success is to “continue to offer an above-average product for an average price.”

Boris Shvab is the owner of Consolidated Technologies, a hands-on automation expert who has also been running his Robot Industries business since 1982.

In the mid-1990s, an industry colleague complained to Shvab about the state of the packaging equipment sector, noting how there were the very expensive machines, but very few quality pieces of equipment at an affordable price.

“With his strong background in automation, Boris took the challenge and built a quality cartoner for a mid-range price, sold it, built another one, sold it and then started up Consolidated Technologies,” states Lapointe.

When Lapointe joined Consolidated Technologies in 2001, he says that while the company had sold a few cartoners since 1998, his job was to heavily promote the packaging equipment.

“Since that time, “I’m proud to say that Consolidated Technologies has earned a well-deserved reputation for our quality equipment at the affordable price,” says Lapointe.

While the company mainly focuses on the Canada and U.S. market territory, Lapointe says that they also have customers in Europe and South America, picked up via word of mouth or from trade show attendance.

“Right now about 70 percent of the business is from the food and beverage industry, 20 percent industrial, and the remaining 10 percent is from the cosmetic and pharmaceutical segments,” explains Lapointe.

He points out that even though Consolidated Technologies has many customers from large national and international food and beverage processing companies, “We don’t actively search out such business.

“We love working with the big companies, of course, but its imperative for us to realize that our strengths revolve around mid-range companies and affordable quality,” Lapointe relates, “and not with extreme high-speed machines at higher price-points.”

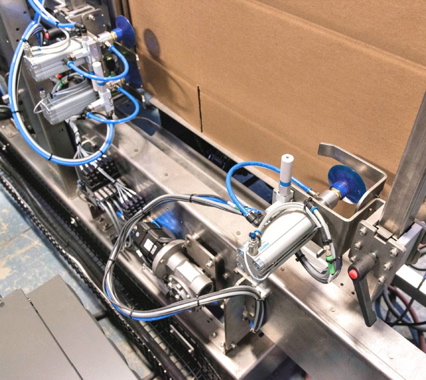

A Consolidated Technologies cartoner in the process of being built at the Vaudreuil-Dorion, Que. facility.

The busy Consolidated Technologies shop often handles up to 15 machine builds at a time, with Lapointe pointing out that while everyone usually works a common work schedule, the people in the machine shop tend to put in extra time everyday in an effort to ensure delivery times to the customer are met or exceeded.

While Consolidated Technologies may have made its name designing and manufacturing cartoners, Lapointe notes that it is no longer the main selling equipment at the company.

“The cartoner is probably a victim of its own success,” says Lapointe.

“Our customers want to continue to automate, and next will purchase a case-packer and later still a palletizer,” he says.

“For them, the single source for a complete end-of-line means not only a single responsibility, but efficient service and standardized spare parts and purchased components.

“It’s why case-packers and palletizers are big sellers for us and now dominate our manufacturing floor over all else,” Lapointe relates.

He adds that while the company offers specific models of machinery, each equipment unit it sells is modified specific to the customer’s predetermined need.

That, along with being one of the few Canadian companies to present the customer with such a wide range of end-of-line equipment, is why Lapointe says Consolidated Technologies has been and continues to be a successful company.

Case-packers manufactured by Consolidated Technologies are equipped with pneumatic products produced by Festo.

“It’s important for us to manufacture the products we sell,” offers Lapointe. “We could have simply purchased palletizers from a reputable company, but then it means I am beholden to them to ensure it is up to the same standards as our own equipment.

“We’re not integrators,” Lapointe states. “We design and manufacture, and have faith in our own equipment and possess the necessary skills to trouble shoot should a problem arise.

“It’s our machines—our responsibility,” says Lapointe. “It’s not just a one-stop shop for a hodgepodge of equipment, customers know they are purchasing from a one-stop shop of our equipment.”

Lapointe emphasizes that as a one-stop end-of-line shop, Consolidated Technologies builds every machine in-house from ‘A-to-Z’.

“The only thing we don’t do, is laser-cut the machine’s frames,” he notes. “But everything else is pretty much all Consolidated Technologies.

“Doing it ourselves allows us to have more control over the final product,” points out Lapointe. “That way when a product leaves our facility, we can have every confidence that the customer is going to get a machine that not only works, but works well performing at the levels the customer expects and needs.”

He says that initially, when a request for a quote comes through, it is up to the sales personnel to properly determine what it is the customer wants, but even after a project is started, the proper details—and quotation— are adjusted to ensure the customer is happy.

“We are always ready to go and see the customer when they are ready to proceed with a project,” says Lapointe adding that he is only too happy to jump on a plane to get the project moving in the correct direction.

For 2016, Consolidated Technologies enjoyed its most-successful year in sales to date, even doubling its 2015 sales figures, which were also pretty good by Lapointe’s reckoning.

“Roughly 50 percent of our sales are repeat business from our customers, year after year,” Lapointe reveals.

“It’s easy to build a machine, but I believe that its due to the reliability of our design and manufacturing capabilities as well as the after sales service we provide our machines across North America are key components to our success,” he says.

“Even for installations of our machines in California, for example, our people, and our people alone from this Quebec headquarters, go to the site and instruct them on the start-up, and how to operate the machine the best way for their needs,” Lapointe notes. “We do not sub-contract our services when it comes to our customers.

“We know how the machines operate—how they are assembled—it just seems that if we teach the customer and service the machines ourselves, it’s just an easier time for the customer.”

Another way the machine manufacturer keeps things simple for the client is by maintaining a pretty steady work force, with the majority of its employees having been with Consolidated Technologies for many years.

“Maintaining a steady employee base is important,” suggests Lapointe. “Not only does it keep training costs down, but since we are so hands on with our customers, they can be sure that if there is a problem with a machine, they can be sure that we will send one of the actual people who built the machine to their facility to provide the best possible solution to get them up and running.

“The customers certainly seem to appreciate that level of service.”

As the purchase order is issued, and the project put into production, Consolidated Technologies has a meeting involving its engineering, electrical and programming departments to discuss the project requirements.

After the machine is built, quality assurance tests are run, to debug it before the customer is invited to the facility to see and physically try the machine themselves.

It is only after everyone is satisfied—including Consolidated Technologies—that the equipment is shipped to the customer where on-site training can commence.

“About 80 percent of the machines built here are standardized based on one of our latest models,” relates Lapointe. “The remaining 20 percent of the machine is customized, predicated on the customer’s products, production speed and facility environment.

“We design and manufacture standardized equipment that is individually customized and adapted to the customer’s needs.”

The standardized equipment offered at Consolidated Technologies are:

- Cartoners: HC-120, HC-3200, HC-4100, VDC-2900 and TSF-60—offered in semi-automatic and automatic, vertical and horizontal, and continuous indexing;

- Case-packers: UNICEL-20R, SLP-25, and WAP-25—featuring robotic top load, side loading and wrap around options;

- Sleever: US-120;

- Single- and multi-line robotic palletizers: R-PAL 30.

End-of-line packaging systems manufactured by Consolidated Technologies are equipped with Markem-Imaje coders, such as the SmartLase C350 unit.

The R-PAL 30 palletizer features a FANUC Robotics-built M-410ic 185 industrial robotic system, programmed by Consolidated Technologies, that is available with manual or automatic pallet handling.

“Of course, regardless of the set-up, the R-PAL 30 palletizer is easy to use,” mentions Lapointe. “The control and interface are user-friendly with operator and maintenance screen.”

“We designed the R-PAL 30 to be an efficient system with low energy consumption and with low maintenance requirements,” he continues. “And the servo-powered FANUC robot is a thing of beauty that is highly-reliable that can work without needing a break to ensure palletizing operations are done in a timely fashion.”

Like the rest of Consolidated Technologies equipment, the R-PAL 30 is a high-quality machine at a mid-range price, engineered to the client-driven value.

“All of our equipment is built with stainless steel and tubular welded platforms,” says Lapointe. “When there’s something we can’t—and shouldn’t build ourselves—we seek out the best equipment to work with, which is why our robotics system uses FANUC Robotics.”

FANUC actually designed the M-410ic 185 to be a four-axis palletizer-specific unit, which shouldn’t be too surprising since the company did build the first-ever palletizing robot.

According to FANUC, the compact M-4190 series featuring a reach of 3,143mm and a load capacity of 185 kilograms, increases throughput on palletizing and handling applications, providing a high-speed palletizing, assembly, machining and parts transfer applications.

Lapointe also mentioned the robotic system possesses a universal end-of-arm tool, and that its slim arm and wrist assembly offer excellent maneuverability in confined space.

Along with using Fanuc robotics for the palletizing options, Consolidated Technologies use Fanuc robots on its case packers, and work with Markem Imaje to integrate its inkjet, laser printer, print-and-apply, case coder options and more within our line.

“However, I can not overstate that what separates us from the competition is our ability to provide multiple aspects of end-of-line equipment to a customer,” relates Lapointe. “Many a competitive company has found its niche producing one type of machine, while we have found our producing multiple types of end-or-line equipment,” Lapointe explains. “And we’re very good at what we do—and that’s based on all the repeat business we do.”

But all that success and knowing its niche has not gone to the collective head of the folks at Consolidated Technologies.

Prior to shipping to a customer in Oregon, Consolidated Technologies tests the Fanuc M3ia robot pick-and-place system at its 30,000-square-foot Quebec facility.

It is always looking at ways to improve its end-of-line machines in ways a customer would appreciate—and sometimes that means tempering the expectations of said customer.

When it comes to technology, Lapointe provides interesting commentary on the current hot-button topic of Industry 4.0, and how it relates to the packaging industry.

“It really does depend on what one considers Industry 4.0 technology to be,” Lapointe sighs. “In my opinion, most people who talk about Industry 4.0 don’t really know what it means.”

He may have a point. Until the Industry 4.0 term was coined about a decade ago, there was no defined Industries 1.0, 2.0 or 3.0.

In fact, even such illustrious magazines as The Economist were, in 2012, calling the new industrial revolution: Industry 3.0.

While Industry 1.0 refers to what we generally acknowledge as the Industrial Revolution sparked by the invention of Eli Whitney’s cotton gin, it wasn’t until about 10 years ago that a German think-thank coined the 4.0 designation, and gave reference to the other eras in between.

“The problem is, that too few people actually know that Industry 4.0 refers to Cyber Physical Systems (CPS) where a machine sends performance data about itself— not the production line—to the Cloud, where software provides detailed analysis and tells the machine how to adjust itself so it can continually provide optimal performance for its owner,” explains Lapointe.

“Most people seem to think it’s as simple as using a smart phone to perform remote access check-in on a machine’s production line performance—I can see it is operating at a rate of 100 units per minute,” he says. “But, that’s not really what Industry 4.0 is really about.’

He points out that with most things that become popular or viral, people and companies often refuse to take the time to fully understand the ramifications of using terms they don’t understand.

“While we may one day provide real Industry 4.0 technology with our equipment, it certainly isn’t cost-efficient to do so at this point in time,” he sums up, “especially with too many other unknowns, such as cyber security.

“But, at least our customers know that when Consolidated Technologies talks about end-of-line equipment, we actually know what we are talking about.”

Advertisement